X axis cable management - Idea - help needed!

Hi

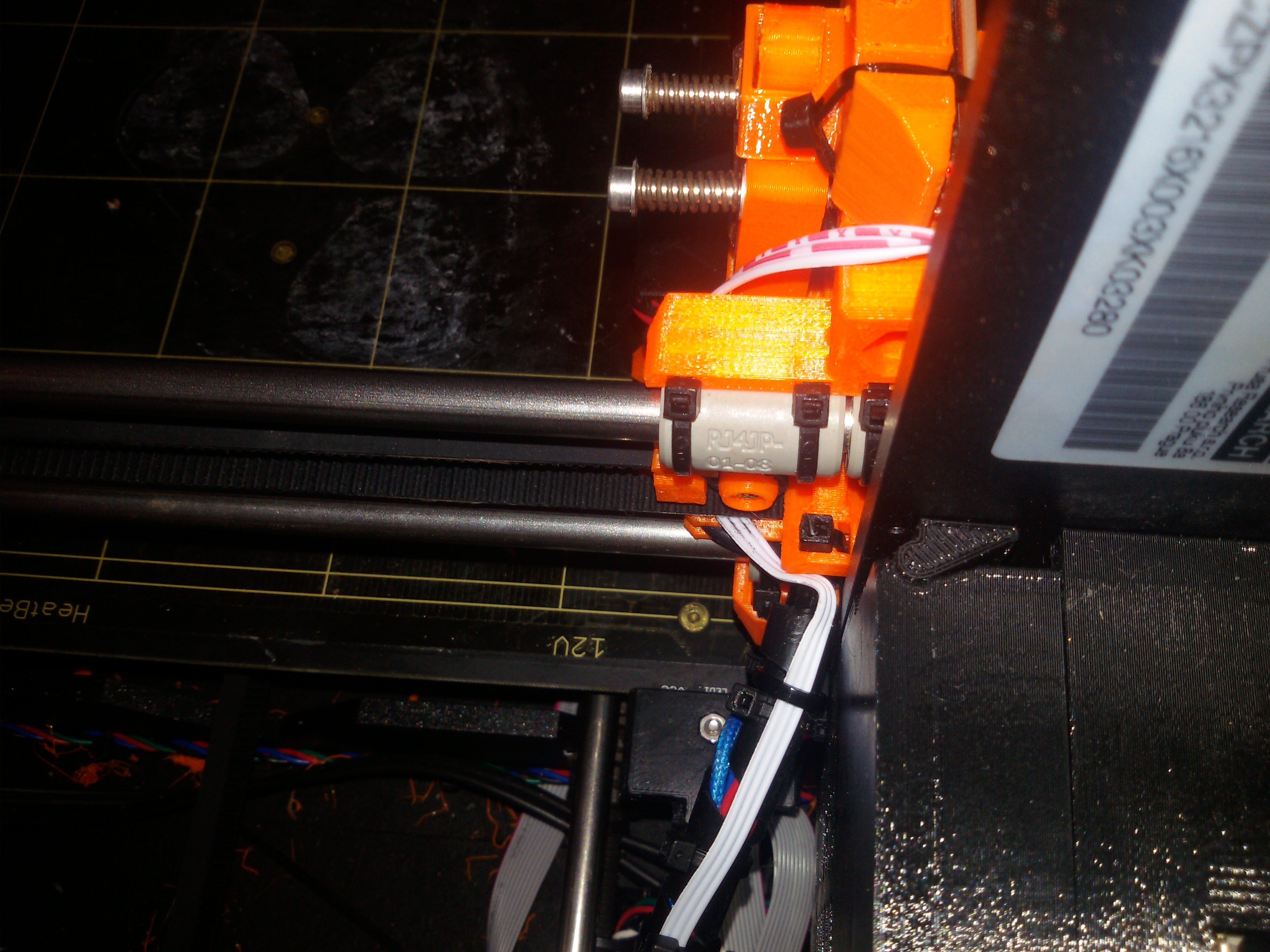

As many of us know the cables from the hotend can sometimes bend the the left side and make it impossible for the carriage to touch the x endstop. This leads to a annoying sound and could also lead to misprints, if the part is so big that the hotend needs to touch the endstop, in order to print the part etc.

There is a thread about this here somewhere but i could not find it.. Nonetheless, I also ran into that problem while i was installing my filament sensor and the cables and probably zip ties bending to the left are the cause here.

Ok so i talked to the support and they said thanks for the finding we will report it to the tech guys, please open a thread on the forum to let other ppl know your idea. So here i am:

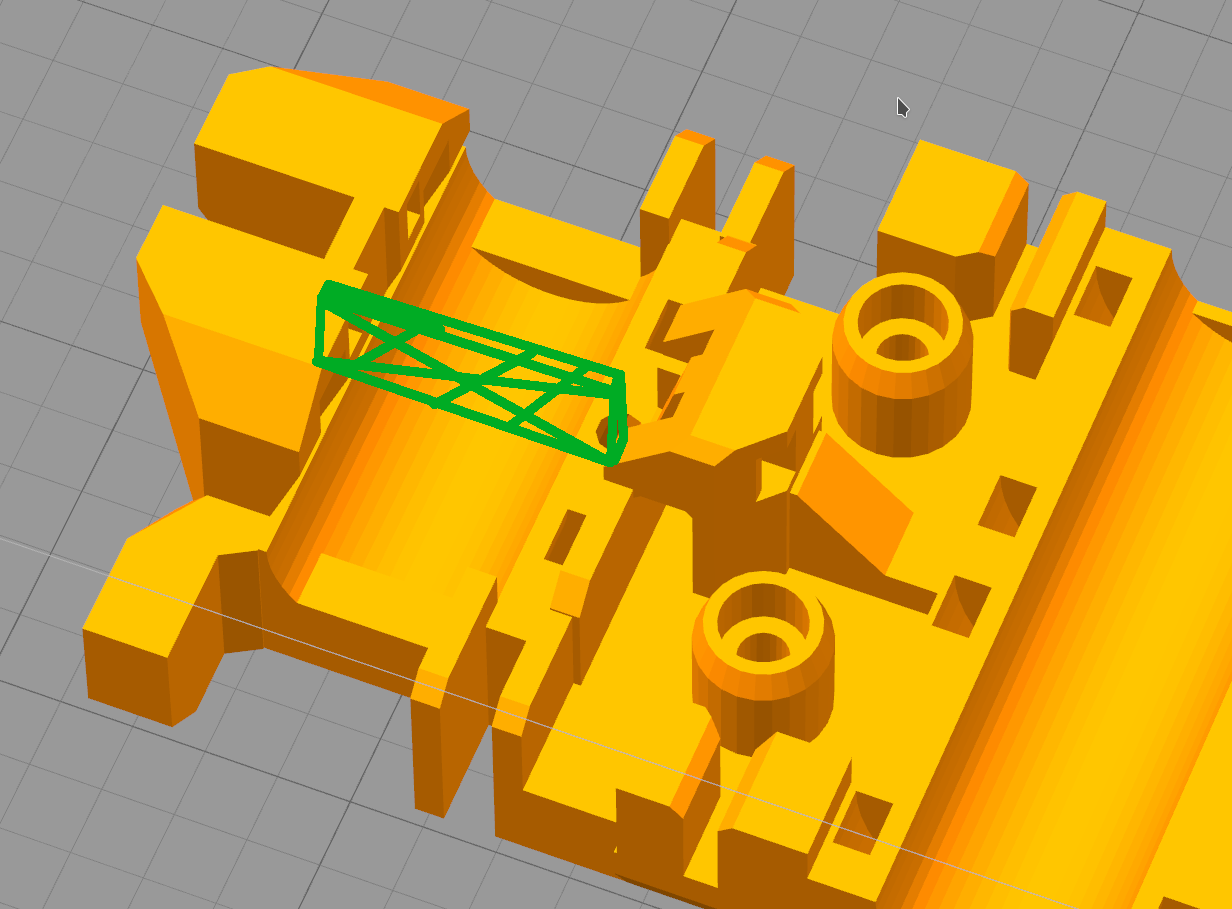

My idea is some sort of shield or cable "tunnel" a bit away from the x carriage so the cables can not bend at there crucial 0.8 cm so the endstop can be reached all the time.

This tunnel or shield could be attached at the small part that holds the ziptie in place who runs up and down to squeeze the bearings and provide a bit of cable management. (The long one).

Here is a mockup:

However, i dont think this is a particular good design as it would have to be very thin like 0.4 mm or so.

Another idea would be to make a zip tie holder on the other side and slightly pull the cables to the right.

So i'm calling for help to improve the design on the idea 🙂

Thanks!

Re: X axis cable management - Idea - help needed!

I think the problem is that your spiral wrap is placed too close to X-carriage. According to assembly manual http://manual.prusa3d.com/Guide/5.+Extruder+Assembly/114 step 37, 38 the spiral wrap must begin wrapping the cables a bit away from X-carriage, this will create the clearance necessary to avoid Z frame collision.

Re: X axis cable management - Idea - help needed!

I think the problem is that your spiral wrap is placed too close to X-carriage. According to assembly manual http://manual.prusa3d.com/Guide/5.+Extruder+Assembly/114 step 37, 38 the spiral wrap must begin wrapping the cables a bit away from X-carriage, this will create the clearance necessary to avoid Z frame collision.

I second this. When I built mine I had the cable wrap all the way up to the X axis carriage like in your picture. This prevented the carriage from reliably hitting the X axis end stop. Starting the cable wrap inch or so away from the X axis carriage resolved the issue.