Z calibration square is curling at the corner. All prints now failing quickly

Hi,

I've been using my Prusa MK3S for a few weeks and prints have been great. I printed the castle and it came out perfect. Then the simplest of prints would fail and end up dragging PLA around the bed in the usual mess until I found it, stopped the print and cleaned it all up.

I ran the Z calibration test again to see if it had gone out of whack. I adjusted it slightly and the lines all had good adhesion and a little squish. However, the square that prints at the end of the calibration print is badly curled up on the left hand side (viewed from front) and seems very heavy on PLA use. All prints are now failing too.

From experience on other printers I know I can fiddle with thing that I think are causing this which leads to new problems and the printer becomes worse so I thought, as a Prusa noob, I'd reach out to all of you for any thoughts.

Thanks

RE: Z calibration square is curling at the corner. All prints now failing quickly

Photo: drag and drop an image of the failed part on the print sheet, before you remove of change anything.

And - it's helpful to know printer model and type of sheet being used, plastic type, brand... Yeah, this is a Mk3 forum, but which Mk3. kit, factory built, etc.

RE: Z calibration square is curling at the corner. All prints now failing quickly

Thanks for the response, happy to provide more information. I have built, from a kit, a Prusa MK3S. The kit was bought from Prusa directly in September.

This is the castle which printed very well, no issues

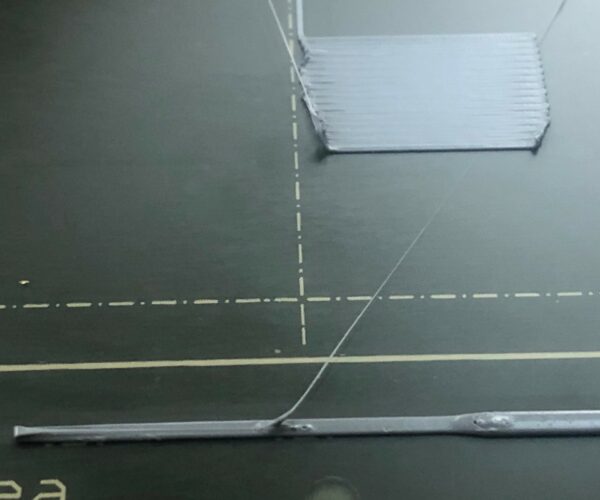

This is what the z calibration print looks like, this is zoomed out to show the purge line too

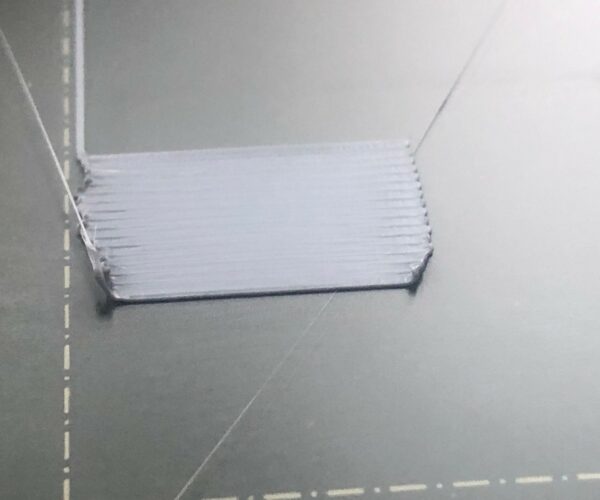

and this is zoomed in to show the curling.

Thanks in advance

Rob

RE: Z calibration square is curling at the corner. All prints now failing quickly

Hi, just to add to this ahead of a response, I am printing using the PLA the came with the printer I am cleaning the bed with isopropyl alcohol before I start. Thanks

RE: Z calibration square is curling at the corner. All prints now failing quickly

Clean bed with dish soap, alcohol does not clean all dirt.

If you change filament pla to something else, always clean bed with dish soap.

then first layer calibration should be 100%.

it also could be bad filament.

Normally not needed:

use glue stick

first layer slower,

first layer hotter,

RE: Z calibration square is curling at the corner. All prints now failing quickly

Keeping the print sheet clean is one of the trickery parts of 3d printing. There are many cases where a release agent is needed; but there are many cases where an ultra clean sheet is required. PLA is one of those ultra clean situations.

Take the sheet to a sink, and using a plain dish detergent like Dawn (US) or Fairy (UK), wet the sheet and with a few drops of detergent and a fresh paper towel, thoroughly scrub the sheet to remove all traces of fingerprints. Handle the sheet only by the edges, and rinse in hot water until the water beads up and sheets off (like a new wax job on a car). With another fresh paper towel, dab off the few remining drops of water, and place the sheet back on the printer. You are ready to go.

Never touch the print surface with your hands. Use tools to lift parts, I use pliers and a plastic razor blade knife or tweezer for small parts.

It's a longish story, alcohol can work as a cleaner, but most don't use enough alcohol to do the job right and leave an oil film that is actually worse than not cleaning at all. Sort of like what you are experiencing. Soap and water just works better, five gallons of hot soap and water at a sink is much more effective than a dab of solvent.

Again, keeping the print sheet clean is a difficult lesson to learn, but once you are in the habit of not touching the print surface, printing becomes fun again.

RE: Z calibration square is curling at the corner. All prints now failing quickly

Some general info ...

When prints are lifting off the bed:

Hot Water wash: often, as needed, and after any of the following

(not recommended for daily use on Powder Coated sheets)

- Handle the bed only by the edges.

- Wash the bed in hot water, use a fresh paper towel as a wash cloth, with a few drops of plain dish soap (Dawn, unscented, no anti-bacterial, etc.).

- Rinse well in hot water - if you have very soft water, rinse a bit longer.

- Dry the bed with a fresh paper towel.

- Handle the bed only by the edges.

- Place bed on printer.

Alcohol wash: very rarely, as needed

- Gloves recommended.

- Once in a while, an alcohol rinse is helpful to remove PLA residue. It does not remove finger oils well.

- Pour a 5 cm puddle of 91%+ alcohol in the middle of the bed, with clean hands use a fresh paper towel to scrub the bed. Wipe up all the alcohol.

- I've developed the habit washing the bed with soap and water after using any other cleaner. It seems to work best.

Acetone wash: infrequent as needed

(Not recommended for USE on Powder Coated sheets, but some find it necessary)

- Pour a 2 cm puddle of acetone on the bed, scrub it around with a fresh paper towel. It will evaporate fast as you clean. This step removes PEI oxides that form over time and with heat, and improves PLA adhesion to a like new state.

Streak test: when contamination is suspected

- With a fresh piece of paper towel, and very clean fingers, dampen the towel with 91%+ alcohol, and wipe the bed side to side moving back to front, like you're painting it with alcohol. The alcohol should be thin enough on the towel it quickly evaporates from the bed. If you see any streaks, the bed is dirty and needs a wash.

When prints begin shifting, start here:

Flat First: Belt drive gears must be tightened flat-first.

1) Start with both set screws fully loosened so the pulley is free to spin on the motor shaft.

2) Align one set screw dead center with the flat on the motor shaft, slowly tighten the screw until it fully contacts the flat surface.

3) Torque the flat set screw to spec.

4) Now tighten the jam set screw, and torque it to spec.

Once tightened, never touch the flat set screw unless the jam screw is first fully loosened.

Why Flat First? Set screws have flat ends. If you tighten the jam screw first the set screw on the shaft flat doesn't fully contact the shaft, only one small edge of the screw surface is biting. Reversing torques can easily shift the shaft to a position the flat screw no longer contacts the shaft. This lets the jam screw wriggle loose. And after a while, vibration loosens the screws until the gear is free to rotate.

Long, but worth reading about getting layer one right:

Live Z Adjust: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way

RE: Z calibration square is curling at the corner. All prints now failing quickly

Wow, thanks to all three responses they are fantastic. For some reason I thought the 91% Isopropyl was the best thing I could use to clean the bed so that is what I always use. I've just washed the bed as described and the print test came out perfectly and I'm printing something more challenging now.

I was just getting to the "I'm not enjoying this problem" stage and this has turned me around. I'm sure I'll face other problems but all your help on this has been invaluable, it is now in a Word document, I might get it laminated

Thanks

Rob

RE: Z calibration square is curling at the corner. All prints now failing quickly

To make it easy, if you have both sheets,

use for petg the powder coated,

pei sheet for pla.

If you use pla on powder coated sheet, this wil stick not as good.

use a big brim, print first layer hotter and/or slower,

use glue stick if needed.