Trying to solve my stringingproblem

Hi all,

I have recently changed my nozzle on my i3 MK3S to 0.25mm because i want to try to print miniatures with this nozzle. I have seen the video on the subject that the difference between 0.25mm and 0.4mm is thin. That however is not what my question is about.

Fillament: Prusament PLA 215 degrees hotend and 60 degrees bed temp

My printer is in an Ikea enclosure solution in my livingroom and i have kept the doors open. My fillament is stored in a compartment above the printer in the same IKEA enclosure solution however the windows are made 'airtight' with rubbertape and the compartment has two giant dry silica sacks inside to keep the fillament dry (one sack is normally for one car). Before i started this test, i recalibrated the printer. I also did a completely new first layertest. All is very well.

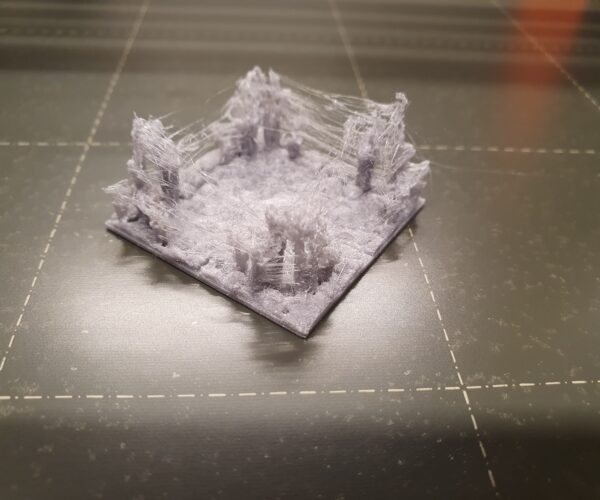

I keep getting stringing problems; with both nozzles by the way. As a test i printed a tile with grass. Not only i get stringing between the grass peaks but also a lot on the floor of the tile:

I then read a post on the subject on this forum to see how others solved their stringingproblem.

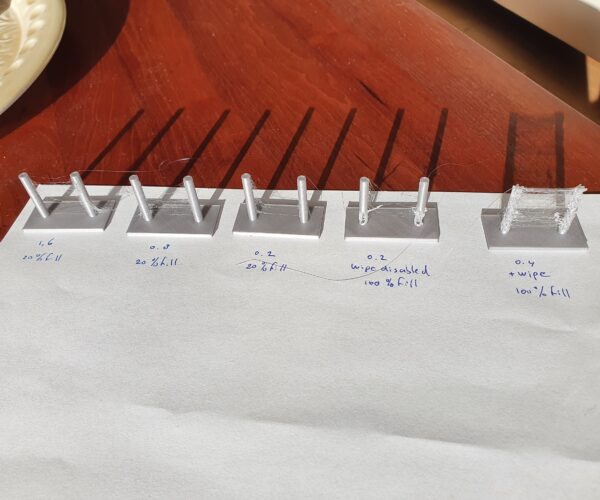

I have changed the retractionsetting (up and down), turned wipe on and off

From left to right:

retraction 1.6mm 20% infill wipe on

retraction 0.8mm 20% infill wipe on

retraction 0.2mm 20% infill wipe on

retraction 0.2mm 100% infill wipe off

retraction 0.4mm 100% infill wipe on

My best print in this set is 0.2mm 20% infill wipe on. However, it still has stringing.

I also wonder how it can be that the first centimeter of the pillars of the fourth testprint is hollow?

Does anyone have an idea?

Thank you!!

RE: Trying to solve my stringingproblem

While I mostly print PETG in the tropics with extremes of humidity I had similar issues. No matter how I store filament it does get wet. Running it in a filament dryer for 4 hours helped some. Feeding from a running filament dryer helped on longer prints. Lowering temps into the lower end of the recommended range made things better. Then for PETG increasing retraction to 3mm (I'd be cautious pushing that far with PLA but you can experiment with smaller increases) with wipe on and a .2mm lift pretty much removed it all. Don't be afraid to keep tweaking things and I have found in my extreme humidity silica is just not enough. Don't know if all this will help but I hope so!

Your filament is wet. Look for threads on here about drying it.

Cheerio,

RE: Trying to solve my stringingproblem

Thank you Sailor Eric and Diem. I'll dry the fillament and try again. I thought i could manage with silica sacks only 🙂

Thanks for the help!