Trying to print NACA airfoil and getting frustrated

I am trying to print a small model rocket fin using a NACA symmetrical airfoil cross section. The fin is about 70mm long, averages 30mm wide, and an average thickness of 3mm (the width and thickness taper toward the tip). I'm using PLA with a 0.4mm nozzle. My print bed is powder-coated and PLA sticks poorly to it, so I always use a brim, which helps.

The problem is the trailing edge. It's basically a knife-blade. I need to print it as thin as possible.

Printing the airfoil standing up vertically (with the root of the "wing" on the print bed), I have to adjust the trailing edge thickness to be about double the nozzle thickness, or about 0.8mm, which is unacceptably thick for a small airfoil like this. This is going on an actual rocket and I need to minimize drag, and a thick trailing edge has a lot of drag.

So I tried printing it on its side at 0.05mm layer thickness (using PLA), with support for the curved airfoil surface facing the bed. That was a disaster. The support structure was printing just fine, but in the actual airfoil, plastic started bunching up in one region after just a few layers. The nozzle kept crashing into this mound of plastic until the whole part broke loose. The printer's crash detection never activated.

It wouldn't be a problem if I had a large airfoil, but this small one really needs a knife-edge. I was hoping to take advantage of a small layer height.

Because the airfoil is symmetric, I could print two halves of an airfoil, but then I run into the problem of first layer height being 0.2mm, which results, again, in a fairly thick trailing edge when I combine the halves together.

Questions:

- Does anyone have suggestions on how to print a small airfoil with a sharp trailing edge?

- Why was plastic bunching up into a mound once the part started printing on the support structure? What could I do about this?

- If I were to print symmetrical halves, how thin could I reasonably go with the first layer?

Thanks.

RE: Trying to print NACA airfoil and getting frustrated

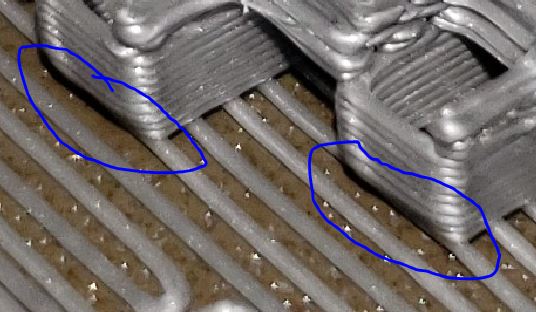

Here is a picture. The raised mound of plastic is in the foreground. I really don't know how I'm going to accomplish printing this object. (picture uploaded upside-down for some reason).

RE: Trying to print NACA airfoil and getting frustrated

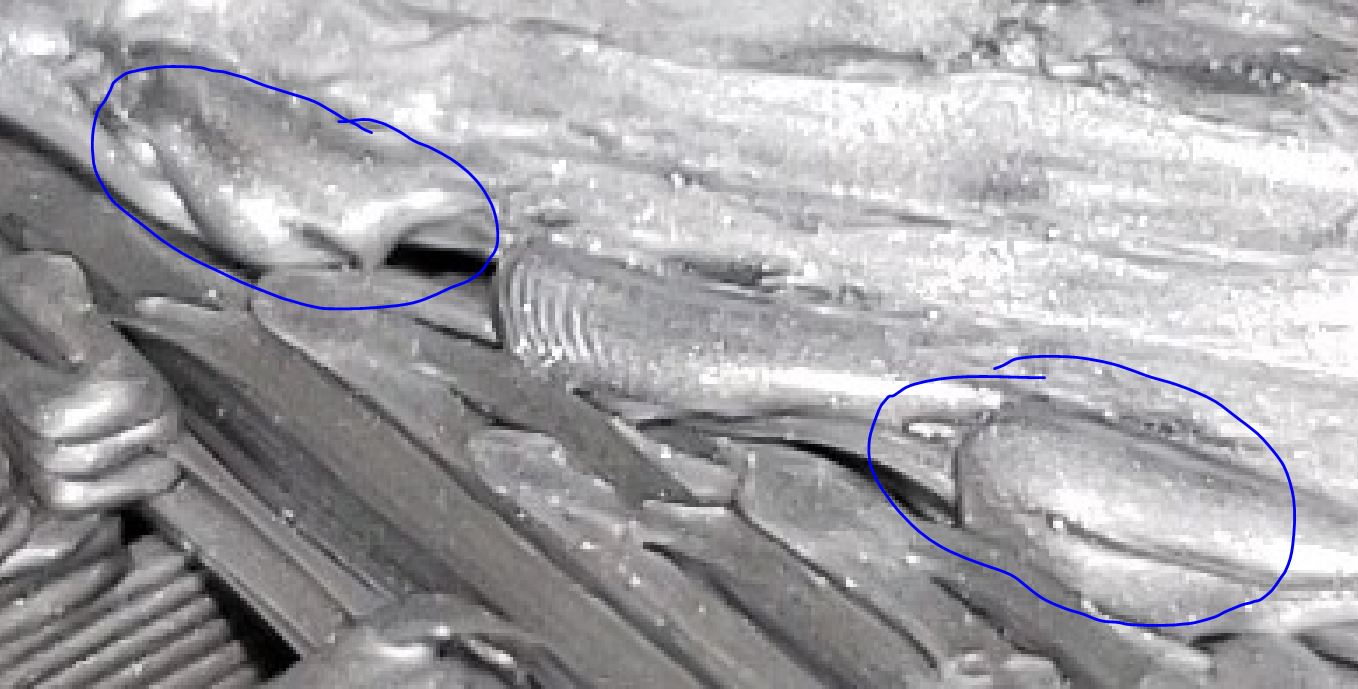

You have more serious print issues than worrying about the edges.

Layer 1 is way to thick (it is nearly round, eek).

You are printing way too hot for the filament.

Your belts are much too loose, and/or you have loose belt drive gears.

RE: Trying to print NACA airfoil and getting frustrated

@tim-m30 - 215 C is way too hot? That's what the printer uses when I set it to preheat for PLA. I'm using the filament that came with the printer.

I can try flattening the first layer, but my recent calibrations show that when I lower the Z axis further, the test pad starts ripping. But I agree, I don't like the look of that first layer either. I've been real frustrated by this. When I've made it flatter, I've seen the filament just drag around the bed without sticking.

The belts are tight, according to what the printer says and what the assembly manual says. Tightening the screws another half-turn woudn't hurt, though.

I've had great prints until now.

I'm more curious about why a mound of plastic formed here. I understand that 0.05 mm layers can be finicky.

The main point of this post was to ask for advice on how to print sharp edged objects. Aside from the first layer, do I have the right idea?

My next test I was thinking of, was to remodel the airfol with dull edges, print it as a vase, and then sand the edge sharp.

RE: Trying to print NACA airfoil and getting frustrated

@anachronist

First layer thickness of 0.05mm won't work. The printer has a minimum height for the first layer (0.2mm I think). You can set the first layer for less in the slicer, but the printer won't actually go below the hardcoded minimum. You end up with a way under-extruded first layer and the following layers are screwy because the actual vs expected height is wrong.

RE: Trying to print NACA airfoil and getting frustrated

Corner should be squared, poor layer adhesion allows filament to drag; and Live-Z is too positive and filament is not forming needed rectangular shape to fully contact bed and provide a good surface to subsequent layers.

The overhang forming above layer 1 are either loose belts or loose belt drive gears. Loose belts are also hinted at by the rather rounded corners during infill, as shown in the last image.

These blobs are either over-extrusion, or by printing too hot and the nozzle is wiping material from prior passes. Also a function of thermal expansion and if the print is warping - both result in the part lifting higher. But the fact there plastic is flowing after it is extruded,points to temperature. It may be some other function, in an enclosure?, but nozzle temp too high for the filament is my first guess.

RE: Trying to print NACA airfoil and getting frustrated

As for sharp edges? Yes and no. You'll find that printing on a raft won't work. Your fin will be quite ugly on the bottom side, ugly enough you probably won't want to use it.

Printing two halves will yield a much better surface quality. It also helps strength because you use the linear extrusion strength rather than depending on inter-layer adhesion/bond strength. But best overall visual quality would be printing the fin vertical, where the fin cross-section will be accurately reproduced.

The sharpness of the fin won't affect airflow over it as much as you are worrying about. It might even help to have the 0.2 mm radius left by the nozzle; especially at scale.

RE: Trying to print NACA airfoil and getting frustrated

I did print an airfoil for a model wind turbine - it was a royal pain to get it right, but I was able to get a single extrusion trailing edge.

I printed it with the leading edge down. It required amazingly clean smooth PEI ... freshly washed and scrubbed in near boiling water and fresh acetone wash to ensure the surface had no oxides. I was depending on two 0.4 mm by 6 inch streaks in contact with the bed to hold up a 12" long 1 inch tall blade. There were many attempts (rafts included).

Depending on just how precise you want the fin, a 0.25 mm nozzle may be in your future. Until then - and I admit I could be 100% wrong - it's my impression you have a couple other print issues that need to be addressed.