TPU Printing - Issues at external perimeter/surface

Hi guys,

I need your help again. For PLA and PETG I'm getting very good results with my new MK3s, but I'm not able to get a clean TPU print now.

I'm printing with a filament from TIANSE. Maybe you never heard about it, but you can get this on Amazon for a good price and my friend is getting very good results with it (also MK3s). The filament is very hard, not very flexible but still elastic - this makes it easier to print and works well for printing drone parts.

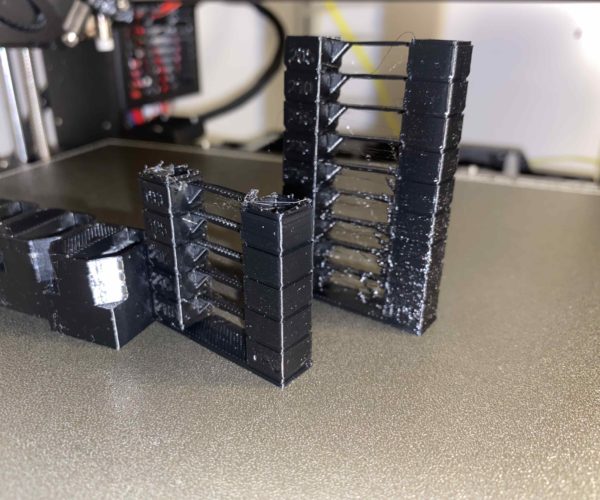

At first I calibrated the linear advance K factor and found that K150 works as the best for me. Then I printed a temp tower to determine the best printing temperature for this filament:

It looks like the print was getting better each time I lowered the printing temperature. With 190°C there was almost no stringing and a nearly perfect external perimeter, but with 185°C the printer stopped to extrude and the filament started to wind around the extruder (this was not easy to remove...)

So, printing with 190°C at the edge of the possible temp range didn't seem to be the solution for me, I thought I was just "working around" another problem. Maybe the printer starts to under-extrude because it can't get more filament through the nozzle because the filament doesn't get that fluid as it should be? I started to play around with the extrusion multiplier, but this didn't affect the result as I expected.

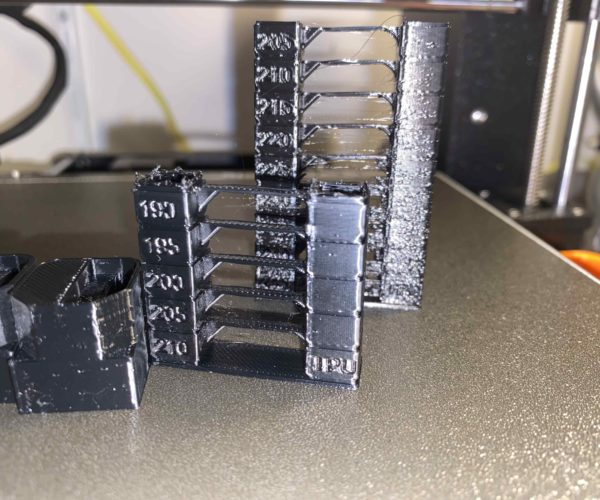

From left to right:

1) 0.95 extrusion multiplier, 210°C, faster printing speed

2) 0.95 extrusion multiplier, 200°C, slower printing speed

3) 1.15 extrusion multiplier, 200°C, slower printing speed

4) 0.85 extrusion multiplier, 200°C, slower printing speed

Any idea what could improve my results? This external surface looks very unpretty for me... Thank you in advance!

RE: TPU Printing - Issues at external perimeter/surface

I'm not sure myself how to answer your issues, but have you tried getting a 3mf file that works on your friend's printer to see how he did it? Also, try to get the gcode from your friend of a successful print to make sure it works on your printer to rule out printer differences vs. slicing settings differences.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: TPU Printing - Issues at external perimeter/surface

@sembazuru

Yes, I already tried to print files from him, but the result is nearly the same. But I have to mention that he changed the original extruder to work around the known issues about the extruder case and the hot bondtech gear due to the direct connection to the motor.

But I saw some nice results from other people here which are printing flex filaments with stock firmware as well 😊

RE: TPU Printing - Issues at external perimeter/surface

What volumetric value do you have set for the filament?

RE: TPU Printing - Issues at external perimeter/surface

Do you mean the "max volumentric speed" value? This is currently set to 15mm3/s.

RE: TPU Printing - Issues at external perimeter/surface

Try to dry the filament.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: TPU Printing - Issues at external perimeter/surface

try setting TPU volumetric to 4 or 5

RE: TPU Printing - Issues at external perimeter/surface

@nikolai-r I opened the filament 7 days ago, it was sealed in a vacuum bag, I don't think it absorbed that much humidity in this time.

@david-a66 Okay, I'll give it a try.

In the meantime, I tried to slice the same object with the same printing temperature with Cura and the generic TPU 95A profile. The result is the cube in the following picture on the right. This looks much better than every cube that was printed with PrusaSlicer, except the stringing at the top. The good part of this finding is that my printer can do pretty results with the filament, the bad part is to figure out which setting is wrong in my PrusaSlicer.

RE: TPU Printing - Issues at external perimeter/surface

I tried to adapt some settings from Cura to my PrusaSlicer profile.

What I changed now:

Max volumentric speed: 15 -> 4

Retract length: 2.0 -> 0.8

Lift Z: 0.2 -> 0.4

Cooling fan speed: 80-100% -> 30-50%

Not sure what was the crucial setting, but the result is very good now (left old PrusaSlicer print, mid Cura, right new settings with PrusaSlicer):

RE: TPU Printing - Issues at external perimeter/surface

If an enclosure is involved, you have to add cooling to the extruder motor. This is an extremely well known issue.

Also - volumetric flow is quite limited for flexible filaments, and is probably what gives the better result.