Surface holes

Hi everybody!

I've been printing with i3 for about 2 weeks now and having some issues with the surface quality.

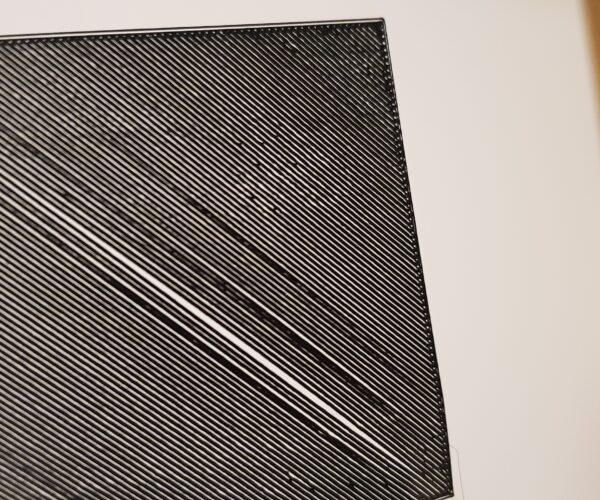

On the both sides of the prints, there are holes on the surface (pic.1).

Printing with PETG (Prusament)

The filament seems to extrude properly, nice even flow.

So i calibrated z axis once more since i wasn't sure it was spot on after the first calibration. It was set to little under -800 before and i printed one test with this value (pic.2). It was just lines next to each other not sticking together, so i tweaked it down to -976 and the lines were sticking together now, but there were holes inside(pic.3).

I made one print with PLA (prusa) and it too hasn't got a nice surface

After that i ran another z axis test and the result was this:

Lines are apart once again and there's some inconsistencies, i know that's what's causing bad surface, but can't figure out why is this happening.

I've tried using Prusa slicer as well as Cura. With prusa i didn't change the settings, with cura i set the retraction to 2mm distance and 45mm/s

speed - it helped to reduce blobs, but the holes still remained.

Any idea what's causing it?

RE: Surface holes

You are not low enough or the nozzle is clogged or under extrusion.

How to make a first layer calibration.

RE: Surface holes

Thank you for your reply!

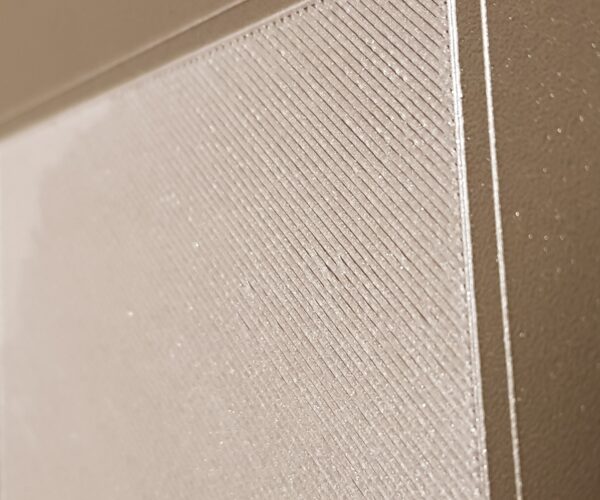

I made one z calibtration test and it looks like this:

Now my extruder started clicking as well, so it might be a clog. Checked the teflon tube and the gears are ok.

What do you use to clean the nozzle?

RE: Surface holes

Search forum or a manual by prusa,

how to do a cold pull

Do this several times to clean the nozzle.

or change the nozzle and you know within a few minutes if it was the nozzle.(manual on e3d is good).

Try different filament(bad filament), and different temperatures( a little higher then it melts more) .

RE: Surface holes

I have done the cold pull for at least 10 times. Cleaned out the nozzle at least 10 times.

Took the extruder apart and changed teflon tube + cleaned the gears that feed the filament. Nothing helps, still the same result.

I know about bad filaments as well. At the moment i'm using original Prusa filament - that shouldn't be bad.

I'm going to order a new nozzle to try it out, but it is not available in my country, so it takes me back a few weeks just to check that...

RE: Surface holes

Check your spring tension, see manual from prusa.

Check if gears are OK, in mk3 the pin which in in the gear could be assembled wrong, if you go to far to one side , it could come loose.

RE: Surface holes

I should have mentioned it, but i encountered this problem on my 3rd day of printing. Extruder started clicking as it was unable to pull filament down, when i centered the pin, it worked for a day and same thing happened. Then i printed a new idler door and it has been ok ever since.

Gears look good as new.

Removed the nozzle today and will give it a proper clean once again...we'll see what happens.

RE: Surface holes

Managed to get my hands on a new nozzle, but it didn't help.

Printed some z axis test circles all over the bed and got different results.

Could it be uneven bed problem?