Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

I am trying to print my PETG parts with as good of a texture as Prusa is able to obtain on my MK3S front panel, which virtually has zero texture defects:

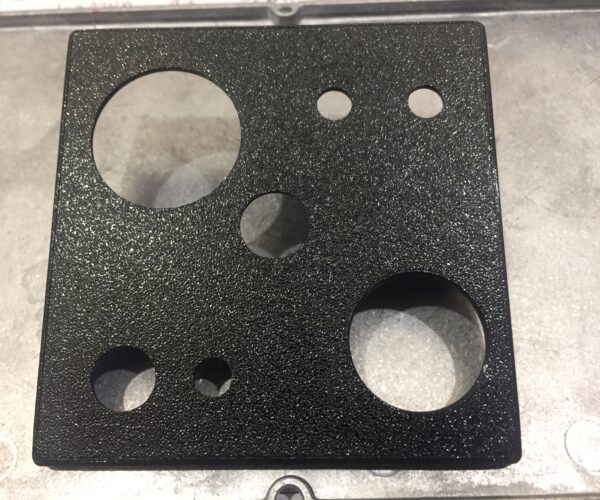

Here is the best I can get so far (I increased all nozzle and bed temp from default values by 5 degC which was better than the defaults):

To me, it appears that the material is not flowing into the texture as well, so higher in temps may work but how high can I go?

What will I see when I get too high in temps besides more strings?

I do not want to have my nozzle seize up with overheated plastic.

Any ideas how to achieve their results?

Are the parameters which they use in their farm available to us?

Dale

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Hi Dale, I don't know about exact factory settings,

If you download a Gcode set from the Prusa Printable files section, there should be a set of settings, included

a bit like this

; avoid_crossing_perimeters = 0

; bed_custom_model =

; bed_custom_texture =

; bed_shape = 0x0,250x0,250x210,0x210

; bed_temperature = 90

; before_layer_gcode = ;BEFORE_LAYER_CHANGE\nG92 E0.0\n;[layer_z]\n\n

; between_objects_gcode =

; bottom_fill_pattern = rectilinear

; bottom_solid_layers = 4

; bridge_acceleration = 1000

; bridge_angle = 0

; bridge_fan_speed = 50

; bridge_flow_ratio = 0.95

; bridge_speed = 30

; brim_width = 0

; clip_multipart_objects = 1

; compatible_printers_condition_cummulative = "printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK3.*/ and nozzle_diameter[0]==0.4";"nozzle_diameter[0]!=0.6 and printer_model!=\"MK2SMM\" and printer_model!=\"MINI\" and ! (printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK(2.5|3).*/ and single_extruder_multi_material)"

; complete_objects = 0

; cooling = 1

; cooling_tube_length = 5

; cooling_tube_retraction = 91.5

; default_acceleration = 1000

; default_filament_profile = "Prusament PLA"

; default_print_profile = 0.15mm QUALITY @MK3

; deretract_speed = 0

; disable_fan_first_layers = 3

; dont_support_bridges = 1

; duplicate_distance = 6

; elefant_foot_compensation = 0.2

; end_filament_gcode = "; Filament-specific end gcode"

; end_gcode = G4 ; wait\nM221 S100\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\n{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+30, max_print_height)}{endif} ; Move print head up\nG1 X0 Y200 F3000 ; home X axis\nM84 ; disable motors

; ensure_vertical_shell_thickness = 1

; external_perimeter_extrusion_width = 0.45

; external_perimeter_speed = 25

; external_perimeters_first = 0

; extra_loading_move = -2

; extra_perimeters = 0

; extruder_clearance_height = 25

; extruder_clearance_radius = 45

; extruder_colour = ""

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; extrusion_width = 0.45

; fan_always_on = 1

; fan_below_layer_time = 20

; filament_colour = #FF8000

; filament_cooling_final_speed = 3.4

; filament_cooling_initial_speed = 2.2

; filament_cooling_moves = 4

; filament_cost = 27.82

; filament_density = 1.27

; filament_diameter = 1.75

; filament_load_time = 0

; filament_loading_speed = 28

; filament_loading_speed_start = 3

; filament_max_volumetric_speed = 8

; filament_minimal_purge_on_wipe_tower = 15

; filament_notes = "List of manufacturers tested with standard PETG print settings:\n\nE3D Edge\nPlasty Mladec PETG"

; filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

; filament_retract_length = 1.4

; filament_retract_lift = 0.2

; filament_settings_id = "Prusa PETG"

; filament_soluble = 0

; filament_toolchange_delay = 0

; filament_type = PETG

; filament_unload_time = 0

; filament_unloading_speed = 90

; filament_unloading_speed_start = 100

; filament_vendor = Made for Prusa

; fill_angle = 45

; fill_density = 20%

; fill_pattern = grid

; first_layer_acceleration = 1000

; first_layer_bed_temperature = 85

; first_layer_extrusion_width = 0.42

; first_layer_height = 0.2

; first_layer_speed = 20

; first_layer_temperature = 230

; gap_fill_speed = 40

; gcode_comments = 0

; gcode_flavor = marlin

; gcode_label_objects = 0

; high_current_on_filament_swap = 0

; host_type = octoprint

; infill_acceleration = 1250

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0.45

; infill_first = 0

; infill_only_where_needed = 0

; infill_overlap = 25%

; infill_speed = 80

; interface_shells = 0

; layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]

; layer_height = 0.2

; machine_max_acceleration_e = 5000,5000

; machine_max_acceleration_extruding = 1250,1250

; machine_max_acceleration_retracting = 1250,1250

; machine_max_acceleration_x = 1000,960

; machine_max_acceleration_y = 1000,960

; machine_max_acceleration_z = 1000,1000

; machine_max_feedrate_e = 120,120

; machine_max_feedrate_x = 200,100

; machine_max_feedrate_y = 200,100

; machine_max_feedrate_z = 12,12

; machine_max_jerk_e = 1.5,1.5

; machine_max_jerk_x = 8,8

; machine_max_jerk_y = 8,8

; machine_max_jerk_z = 0.4,0.4

; machine_min_extruding_rate = 0,0

; machine_min_travel_rate = 0,0

; max_fan_speed = 50

; max_layer_height = 0.25

; max_print_height = 210

; max_print_speed = 200

; max_volumetric_speed = 0

; min_fan_speed = 30

; min_layer_height = 0.07

; min_print_speed = 15

; min_skirt_length = 4

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = {input_filename_base}_{layer_height}mm_{filament_type[0]}_{printer_model}_{print_time}.gcode

; overhangs = 0

; parking_pos_retraction = 92

; perimeter_acceleration = 800

; perimeter_extruder = 1

; perimeter_extrusion_width = 0.45

; perimeter_speed = 45

; perimeters = 2

; post_process =

; print_host =

; print_settings_id = 0.20mm QUALITY @MK3

; printer_model = MK3

; printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK3\n

; printer_settings_id = Original Prusa i3 MK3

; printer_technology = FFF

; printer_variant = 0.4

; printer_vendor =

; printhost_apikey =

; printhost_cafile =

; raft_layers = 0

; remaining_times = 1

; resolution = 0

; retract_before_travel = 1

; retract_before_wipe = 0%

; retract_layer_change = 1

; retract_length = 0.8

; retract_length_toolchange = 4

; retract_lift = 0.6

; retract_lift_above = 0

; retract_lift_below = 209

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 35

; seam_position = nearest

; serial_port =

; serial_speed = 250000

; silent_mode = 1

; single_extruder_multi_material = 0

; single_extruder_multi_material_priming = 0

; skirt_distance = 2

; skirt_height = 3

; skirts = 1

; slice_closing_radius = 0.049

; slowdown_below_layer_time = 20

; small_perimeter_speed = 25

; solid_infill_below_area = 0

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 0.45

; solid_infill_speed = 80

; spiral_vase = 0

; standby_temperature_delta = -5

; start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}200{elsif nozzle_diameter[0]==0.6}24{else}45{endif} ; Filament gcode"

; start_gcode = M862.3 P "[printer_model]" ; printer model check\nM862.1 P[nozzle_diameter] ; nozzle diameter check\nM115 U3.8.1 ; tell printer latest fw version\nG90 ; use absolute coordinates\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0\nM221 S{if layer_height<0.075}100{else}95{endif}

; support_material = 0

; support_material_angle = 0

; support_material_auto = 1

; support_material_buildplate_only = 0

; support_material_contact_distance = 0.1

; support_material_enforce_layers = 0

; support_material_extruder = 0

; support_material_extrusion_width = 0.35

; support_material_interface_contact_loops = 0

; support_material_interface_extruder = 0

; support_material_interface_layers = 2

; support_material_interface_spacing = 0.2

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 2

; support_material_speed = 50

; support_material_synchronize_layers = 0

; support_material_threshold = 55

; support_material_with_sheath = 0

; support_material_xy_spacing = 50%

; temperature = 240

; thin_walls = 0

; threads = 4

; thumbnails =

; toolchange_gcode =

; top_fill_pattern = rectilinear

; top_infill_extrusion_width = 0.4

; top_solid_infill_speed = 40

; top_solid_layers = 5

; travel_speed = 180

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; variable_layer_height = 1

; wipe = 1

; wipe_into_infill = 0

; wipe_into_objects = 0

; wipe_tower = 1

; wipe_tower_bridging = 10

; wipe_tower_no_sparse_layers = 0

; wipe_tower_rotation_angle = 0

; wipe_tower_width = 60

; wipe_tower_x = 170

; wipe_tower_y = 125

; wiping_volumes_extruders = 70,70

; wiping_volumes_matrix = 0

; xy_size_compensation = 0

; z_offset = 0

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Hi Joan, that is great info, I will get those gcode files and have a look.

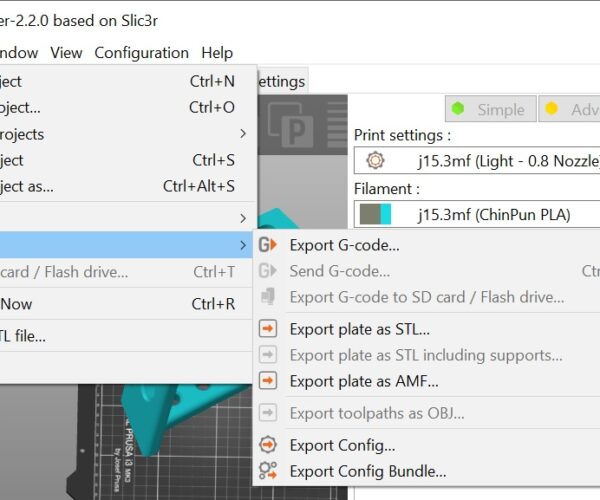

I see that PrusaSlicer can export gcode easily but what about importing gcode so that I can use the settings in the gcode files in PrusaSlicer, if not can gcode settings be converted to ini files?

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Hi Dale,

You can use

Export config and import config, to move and save setup info...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Hi Joan, I am unable to find the gcode here: https://www.prusa3d.com/prusa-i3-printable-parts/

I only see options to get MK3S stl files which won't have the Prusa settings in them:

Is there another place to look for the files, Google didn't help with a "prusa printable gcode files" search...

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

But I do not see a way to import config info or Prusa settings from a gcode file, I only see export to a config file, am I missing something?

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

BTW:

I have figured out how to achieve a similar quality texture but I would still like to see the gcode files with their settings in them 😉

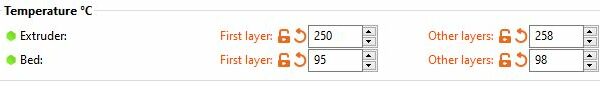

1. My temps were (E&B_250,95_1st_then_258,98)

2. Lowered 1st layer thickness from 0.2 to 0.15

3. Set LiveZ so that it looks like the nozzle height on 1st layer is a little too low.

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

But I do not see a way to import config info or Prusa settings from a gcode file, I only see export to a config file, am I missing something?

Try File->Import config and select an existing gcode file. If the gcode was generated in PrusaSlicer (or its predecessor Slic3r), the settings will be imported.

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Ah thanks and sorry, I missed the fact that a config.ini could be imported and created from a gcode file 🙂

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

hey @dalekramer

were you able to achieve the first layer texture quality of the original Prusa parts? if so, what is the solution?

RE: Printing PETG on textured powder coated sheet with same quality as Prusa obtains on the MK3S front panel face?

Yes, monatomic fill method solved everything.