snot leading to fill grabbing and layer shift

this is getting frustrating ... I am so close to getting almost perfect larger prints I guess next step is to make my own slice and slow down the infill speeds but that does not help the tiny shifts seen higher up in the print.

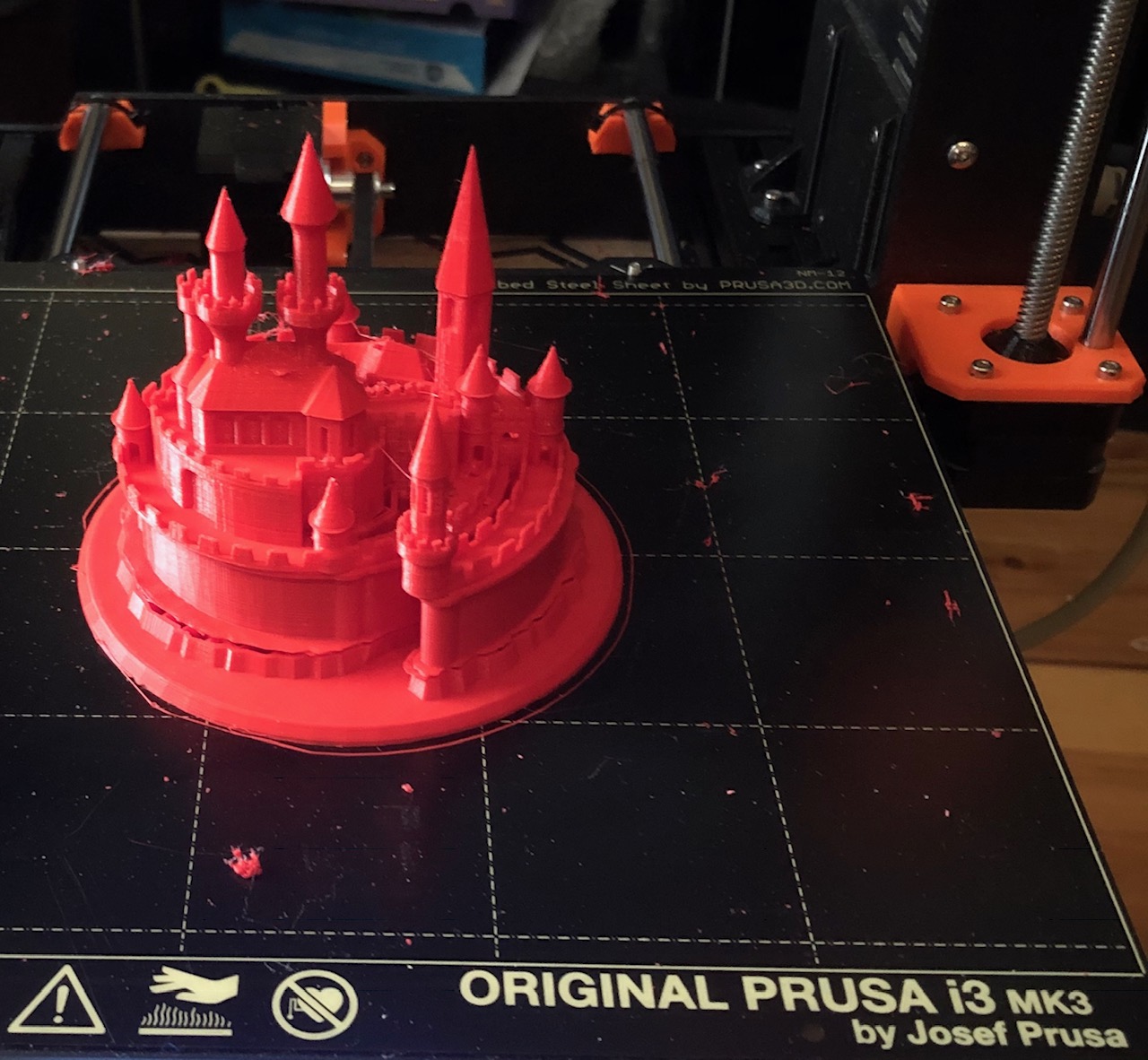

0.10 layer hight 0.4 mm nozzle Prusament lipstick red pla 13 hour print from Prusa provided Gcode

of this file from the MK3 software download but I don't see then as separate downloads on the site

Applications ▸ Original Prusa Drivers ▸ Objects ▸ Sample Objects Castle.stl

print paused and large amount of snot removed from nozzle area this was after the large area grid infill was done I think the speed of the infill has something to do with this snot accumulation

and then print was resumed over night.

note the layer shift right at the level where this was done... there are tiny shifts of much less than 1 mm higher up in the print but the design of the print makes them hard to see in general this is a fantastic print were it not for those items a bit of tweezer work to get the spider webbing and random bits of snot the pointy bits are very pointy and the detail is good but the snot/layer shift is problematical

needless to say the usual suspects for layer shift have been checked and found to be ok...

one other item this is with an e3d nickel plated solid copper nozzle (i have their nickel plated solid coper heat block but I have not yet installed it.

Re: snot leading to fill grabbing and layer shift

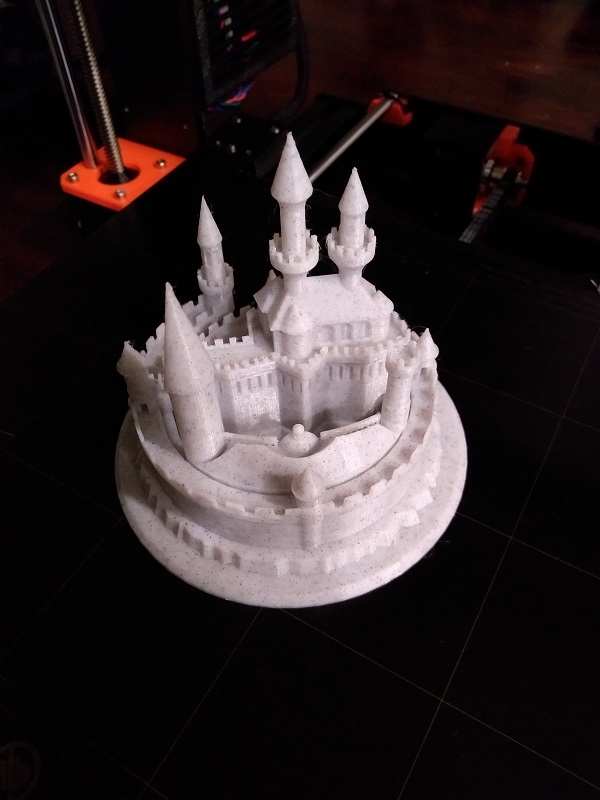

I printed that castle and had zero problems except the marbled filament was pretty stringy. Your print looks suspiciously like some I've seen where the bed adhesion failed and the part warped, causing the nozzle to drag across the part extruding out the sides and making a mess. aka Layer 1 Cal and Bed Cleaning.

And beware of using the Copper Plated Nozzle - it takes very little abuse to destroy one. Image below of one that was shot after 250 grams of Glow PLA. E3D says they are recommended for high temperature applications only. Apparently the nickel plating is the soft kind, not the hard kind. E3D was kind though, they said I must have a really good printer for the wear to be that precise. 😮

Re: snot leading to fill grabbing and layer shift

Interesting Tim, the part was still attached to the extent I had to bend the sheet for it to pop off while a lot of my PLA prints just detach themselves when the bed cools. this was one of my first prints after I got the smooth PEI sheet... today I am back with a project with PETG and the powder coated sheet where I have much better luck . looks like I need more practice with the smooth sheet

Re: snot leading to fill grabbing and layer shift

To be honest, I fought adhesion for a while. It wasn't until I used acetone to clean the bed that I began getting good adhesion. That and learning even one fingerprint is a disaster. Now parts like that castle are difficult to remove, and bending the plate still requires a plastic tool to get under and pry the part off.