Small gear print is terrible

I'm a little at the edge of my capabilities, but I'm determined! There's this little helical gear on the end of a small electrical motor that drives other gears to set the rear-view mirror. All of the gears are in perfect shape except the ones on the end of the motor. They want $250 for a replacement motor! I can print this little gear for cents!

But I've been having a terrible time getting anything close to a usable print. Any suggestions?

I'm using petg and I've tried 10, 15, and 20 for print settings with 50% fill. (I don't think fill matters at this size.)

My first layer is perfectly set and I use the highest setting for pre-print calibration (all latest software and drivers.)

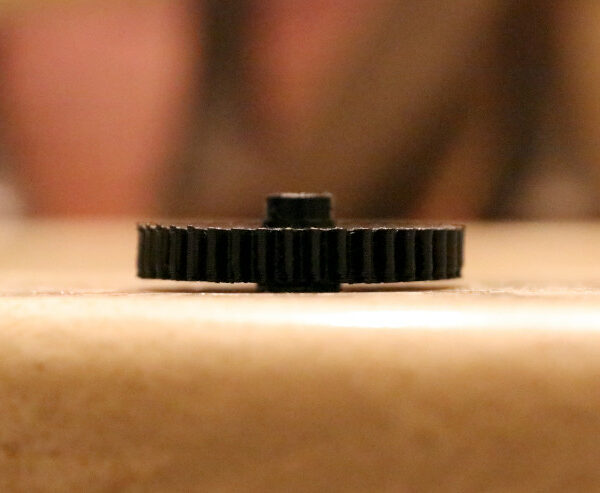

The little black gears are my print attempts. They should be 7mm wide, but they are coming out as 6.5mm wide. They SHOULD look like the white gear in the picture using the same thread pitch and size. Just 7mm long instead of the length of the white piece.

RE: Small gear print is terrible

Here's the STL that SHOULD work, but isn't... Am I slicing this wrong?

RE: Small gear print is terrible

You need to zip files to attach them. If you don't then the forum just silently doesn't do it.

Ideally we need more than an stl (but thats a start). What we need is your project file saved from Prusa Slicer. File>Save Project As. Same rules about zipping it up to attach apply. A project is a snapshot, it contains not only the model but ALL the settings used, its placement, any modifiers etc. It allows someone else to slice it exactly the same as you are doing and check though the previews.

We also don't have to play 20 questions about settings.

Beyond that when troubleshooting potentially difficult parts its often a good idea to try printing it in PLA first to work out if it is printable. Once you have a sucessful print in pla then you can look at what's needed to print it out of your target material.

RE: Small gear print is terrible

Thanks @Neophyl !

Attached is the zip file with the stl and the project file I last used.

I don't own any PLA. I have 10+ spools of PETG in various colors since nearly 80% of everything I print is for outdoor or "stressed-environment" use. You just reminded me; however, I DO have a spool of ASA if I need it for this. Should I get a spool of PLA for this type of difficult prototyping? I never got the impression that there was much difference to printing PLA or PETG, but I'm certainly not the genius in this stuff or I wouldn't be here asking the question. 🙂

RE: Small gear print is terrible

PLA and petg do print quite differently in practice. That is a very challenging print due to several factors. Its at a size where I would normally say print it on a resin printer 😉 Secondly the worm gear 'teeth' are mainly overhang, especially at the 0.15 layer height you are using.

I did print one out of PLA though, its not perfect as the outer edges of the teeth have a tendency to curl up. Its way better than the ones in your picture though. Thats with pla, petg curls up /contracts more. For this project I would suggest you dig out that ASA you have. Its a far more suited material for gears. IIRC some of the more popular 3d printing youtubers like CNC kitchen or Angus from makers muse have done tests and found that pla gears actually last longer and work better than petg ones as the material is more rigid. ASA is better though.

First thing you need is to drop the layer height to 0.1. That stops most of it being overhang. I'd flip the part over too to give more surface area in contact with the bed.

The melting you are getting is quite common on thin posts with the default filament cooling thresholds too. You need to change the slow down if layer print time is below xx down to a very low number so that it doesn't slow down. When it slows too much it stays in contact longer and the heat just builds up more and more and it prints on a non cooled previous layer. Fan speeds are low with petg (or ASA) so you can experiment with increasing them slightly. With such a small area getting hot that can counter the heat build up.

One thing I noticed, why the heck is your extrusion multiplier for this filament 0.85 ? If I had to set it that low to print I'd be looking for something physically wrong with my printer. Personally I find that measuring the actual real world diameter of my filament and plugging that number in results in my EM being=1 on all my prints. Every extrusion calculation is based on that filament diameter, if your real filament is 1.76 then it will be pushing more plastic through. Accurise it and you find that you rarely need to touch EM.

Filament EM settings aside heres the one I did in PLA

The curl upwards at the edges would probably wear down with a bit of a run in against another matching gear.

I've attached a modified version of your project in your petg with some cooling setting changes as well as dropped to 0.1 on the print settings. Worth a go as its such a short print time.

Beyond that I'd experiment a bit with your fan speeds and also try out the ASA. Id change the ASA filament profile too for the slow down in print time is below xx value too as the Prusa defaults have them pretty high which is ok for 'most' things but not so much for thin small cross section bits.

RE: Small gear print is terrible

Awesome! Thanks! I'll try that and report back.

Definitely prototype gears in PLA. You are running into the approximations used when representing curves with triangles in generating meshes; a couple of print, measure and calibrate cycles should be enough.

Polyamides such as PETG and even nylon do not make good printed gears and bearings at small sizes but you do have the option of printing a slightly oversized blank and machining to fit if you have access to a small lathe...

Cheerio,

RE: Small gear print is terrible

@neophyl, thanks again!! I don't recall exactly why the .85 was in there. I think there was a brand of PETG I tried last year that required it. I guess I forgot to change it back. I did, and that definitely helped. I guess between the temp/hover suggestions you put in the project file and changing it back to 1 was the magic sauce I was looking for.

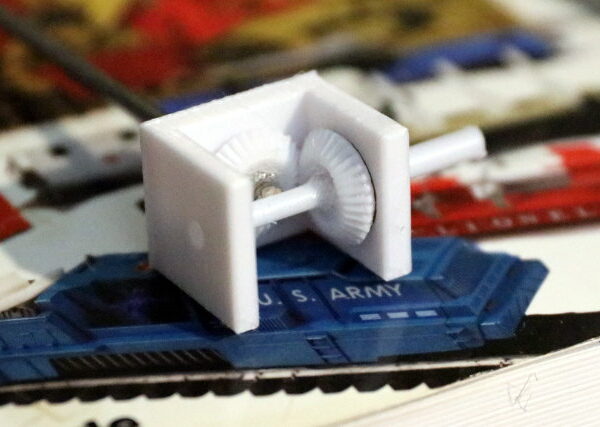

Here are two prints I made in white ASA. The first one on the right was a bit too small on the pitch, so I stretched it out a bit and it and the newer one on the left is really close to what I need. Still need a little more pitch.

It also doesn't seem to suffer from the overhangs like the PETG did, but that could have been from the .85 setting squishing too much filament. Anyway, thanks again!