Recommendations/rules of thumb for printing Tall-Thin objects

Hey all,

Very new and have printed maybe 20 models in last week. I'm looking to start printing a few models that are tall and thin. I am doing my initial one by laying it down, but would like to try standing up.

It seems there must be a standard diameter-to-height ratio, print speeds, acceleration, nozzle temps, pause between layers, which determines if a model will succeed or fail without supports and/or brim?

Can anyone recommend some reading material on the subject?

Thanks!

RE: Recommendations/rules of thumb for printing Tall-Thin objects

I've printed assembly pins that are 35mm tall, 4mm in diameter for the most part, with kind of a 6.5mm 'nail head' at the base, on the smooth plate, in both PLA and ABS with no brim and a light coat of Layerneer on the plate.

To assemble properly, these have to be close to perfectly round, and they are. Very little artifact on the MK3S.

I do these 2-up and 4-up at times and the come out very consistently good.

I do nothing as far as adjusting the default parameters in the slicer. I've found that it's very rare that those settings need to be tweaked.

Using those proportions, you can compare with your models and maybe get an idea if they will print, but the best thing to do, actually, is to try it.

Also some of those 'torture test' prints will have small vertical cylinders which you can try and see how tall thin parts print on your machine.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

I don't normally use anything on the bed for PLA (haven't tried ABS yet), but I do wash the smooth sheet with Dawn dish soap and HOT water if I want it to stick well. Much better results, for me, than alcohol. I use alcohol when I'm lazy and want to 'cheat' a few more prints before washing. If it's small or a complex part, I wash the sheet.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

Use the Print settings presets labeled "Quality" or "Detail", because speeds are slowed down and it is less likely the model will detach.

I nearly always use the Prusa glue stick. Only Downside is you have to apply it and maybe have to clean the model afterwards.

RE:

Do you all do these tall-thin prints without brim or supports?

I'd like to print something which is about 8mm x 6mm x 17cm. I can't see this not falling over.........

I just completed a cylinder which was 8mm dia x 4cm with a brim successfully on smooth PEI PLA with no issues....looks great.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

Do you all do these tall-thin prints without brim or supports?

I'd like to print something which is about 8mm x 6mm x 17cm. I can't see this not falling over.........

I just completed a cylinder which was 8mm dia x 4cm with a brim successfully on smooth PEI PLA with no issues....looks great.

170mm is quite tall, but my hunch is that if it's 8mm x 6mm at the base, it will print fine.

You might add a brim just to be sure.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

My main concern with a 8mm x 6mm tower that high isn’t it coming loose it’s that towards the top it will flex more and you get the possibility of uneven layers. Without seeing the actual model though it’s hard to judge. I know for tall thin things in the past I’ve modelled in sloping supports that join part way up to act as trusses to stop lateral movement.

RE:

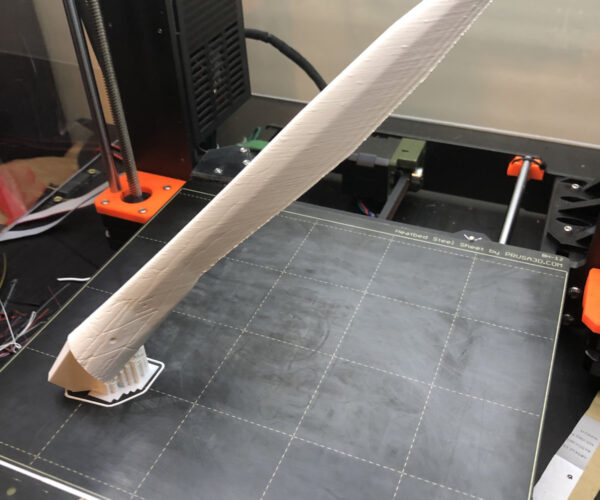

Pla on smooth sheet with nothing but fairy and hot water clean, about 2 weeks ago. Almost full height, around 200mm

WOW this print is amazing! I had no idea the bond between build plate and model could withstand these kinds of forces. Great Job!

I really like the idea of angular support part way. Could you share a file where you have done this so I can see your method? or a picture?

RE: Recommendations/rules of thumb for printing Tall-Thin objects

I'll see what I can find in my archive when I get home. I probably don't have any pictures but should still have the models in blender I generated the stl files from.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

@robin-2

I agree with Neophyl, as you get taller you have a good chance of experiencing wobble, one thing you can do is slow the print down as it approaches a certain height, you will have to take cooling into account as you slow the speed.

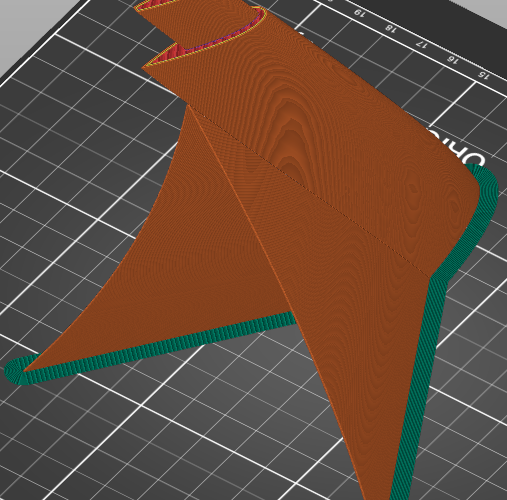

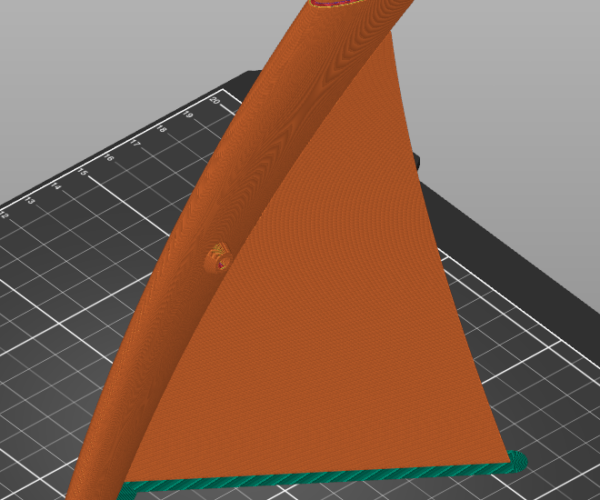

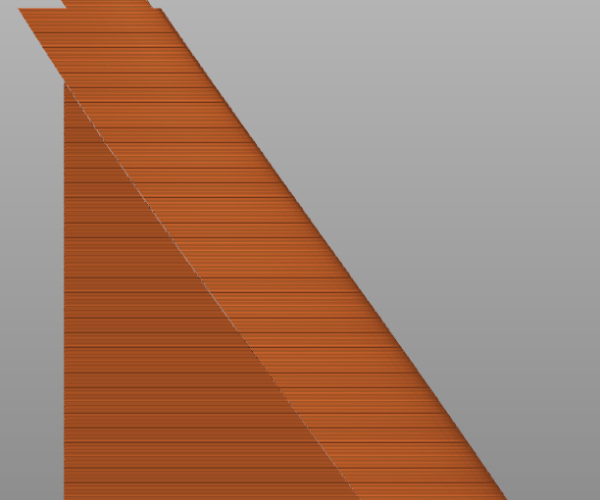

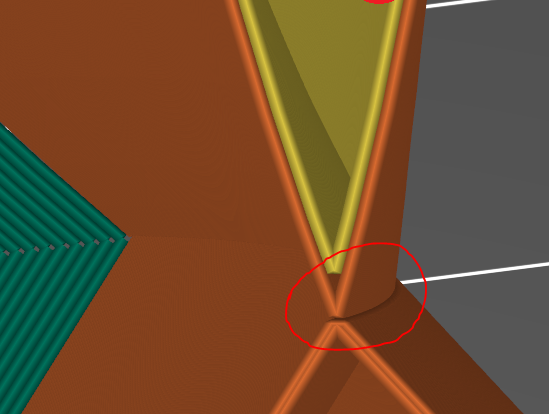

Here an example of a support solution I used on a 170mm tall part, it was added just to stop wobble, and designed to just pop off after completion. I was able to print full speed for the entire print without the effects of wobble.

Note the Gap, if I remember right, it was about 0.2 allowing for the support to be snapped right off after printing.

The supports are 0.84 thick, and I added a brim for the supports.

The base is approx. 9.5mm X 39mm, and it will print without support.

But definitely printed faster and better with them in this case with them.

These are a couple of the finished prints one with supports still attached and same print with the support removed after printing.

Maybe this will help give some idea of the range of techniques that can be employed towards printing tall thin parts.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Recommendations/rules of thumb for printing Tall-Thin objects

Great job! Thanks for the hints! Is there a way to build supports like these in prusa slicer, or is the only way to model them?

RE: Recommendations/rules of thumb for printing Tall-Thin objects

There's no way you will get ones as elegant as THOSE using slicer. They make my modelled in ones look clunky by comparison 🙂 . You can sometime use modifiers to crudely do it in slicer depending on the model but it will take you much much longer to do it and they wont be as good.

It really does pay dividends to learn at least one cad program. In the end you will save time and it opens up many more avenues to you.

RE: Recommendations/rules of thumb for printing Tall-Thin objects

Yes that is what I expected. Too bad, would be nice to have an "All-in-one" solution. I'm previously strong with Solidworks and Sketchup and now I've had a hand at Fusion 360 but have never yet tried manually adding in supports. Will be a fun challenge when needed! 🙂

RE:

Well yeah, you know you need a 3d program to do that, I guess I should have mentioned that. all I was intending was to show your not stuck with slicer. if you need a solution Blender is a great alternative, I don't use Blender exclusively, but I'm a strong supporter.

SolidWorks is great also, at work we have integration with our Stratasys machines.

The Filament Whisperer