PrusaSlicer- Print problems

I have been trying to print this back plate . I have modified it to have two holes in it (one square and one round) , but when I put through the slicer the holes disappear?

What am I doing wrong?

RE: PrusaSlicer- Print problems

Firstly there is no attachment on your post or pictures so its kind of hard to know whats wrong. It is highly likely though that the model has one or more errors. That's the usual cause of these sorts of issues.

If you are on Windows 10 you can right click the model and use the fix through netfabb option. That is a very good method than can usually fix issues. If you arent on windows 10 you can use the netfabb online service to fix them instead.

If you save your project file (File > save as) in Prusa Slicer and then take the resulting .3mf file, zip it up into an archive and then attach the zip file here we can take a closer look. It needs to be zipped up for the forum to accept it. Your project .3mf file will contain the models and all the settings you are using to slice with, so any modifiers etc as well as model positioning etc will be saved. This allows much easier debugging of issues.

RE: PrusaSlicer- Print problems

Many thanks File attached

RE: PrusaSlicer- Print problems

Try again. Still no file. Either use the attach file button or the Add Media button.

RE: PrusaSlicer- Print problems

I tried to attach a STL file but it says that it is not allowed

RE: PrusaSlicer- Print problems

As I mentioned above you have to zip up files for the forum to accept them. Only pictures are allowed. Also a saved project file is better than a stl.

RE: PrusaSlicer- Print problems

Now Hopefully File attached

RE: PrusaSlicer- Print problems

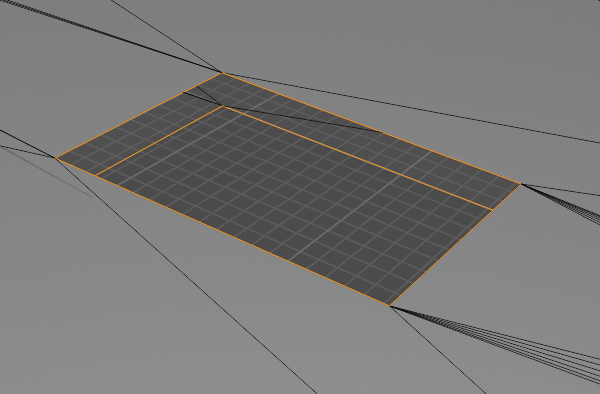

Ok that worked that time. I can already tell you that the model is not fixed by netfabb which means its quite badly broken. It has 60 non manifold edges and 66 intersecting faces according to Blenders 3dprint tool.

Looking at it in blender its apparent that your holes are not filled in. They do not have faces where they cut through the face plate geometry.

For example your square hole. Because there is no connection between the vertices of the hole edges (connecting top and bottom of the holes) all the automated repair tools (and slicer) will just fill in the faces, leaving no holes.

Its not too hard to manually fix though on such a simple model. See attachment with a fixed stl inside.

RE: PrusaSlicer- Print problems

Magic! thanks I will have a look in Blender

RE: PrusaSlicer- Print problems

I cut the hole using Freecad by drawing the hole using a sketch and then switched to Part and Extruded the hole and then Slice Apart then delated the Extruded part which left me with the back plate and what I though the hole?

RE: PrusaSlicer- Print problems

Your faces have a hole in them, on both sides. Unfortunately the 2 holes arent connected together.

Imagine you have a ship with a double thickness hull. You cut a hole in one hull and a matching hole in the other, both above the waterline (dont want the ship sinking now do we). Its great you can now see through it, Its mostly a window. Unfortunately you can also see into the area between the hulls. If it rains or the waves get high then water is going to get into the space between the hulls, that will cause the ship to sink. You need to fill in the edges of the hole for the window to make your hull watertight again.

Thats basically the 3d modelling term for being manifold. ie water tight. If a model isnt manifold then its technically not printable. Most slicers will try and automatically fix these issue when they slice. Same with the auto fixing programs. Software can only guess so much though so in your case it filled in the 2 cuts you had made to make the model watertight/manifold.

RE: PrusaSlicer- Print problems

I use Freecad quite a bit. It's a great design tool, but does have some quirks.

Switching between the various workbenches can be tricky and can result in corrupt results unless you are very careful.

I would suggest that you do most nontrivial but simple designs using the 'Part Design' workbench, rather than the 'Part' workbench. It has a seamless interface into the Sketcher and has the basic add and subtract operations. It's more foolproof than the Part workbench.

The Part workbench does have its place, for basic designs that are mostly additive. With care, you can combine operations of Part and Part Design, but it's easy to get objects that do not print as you would think by trying it.