Prusament PETG help

I’m new, and struggling. I3 MK3s+, using Prusament PETG trying to print spare parts from Prusa.

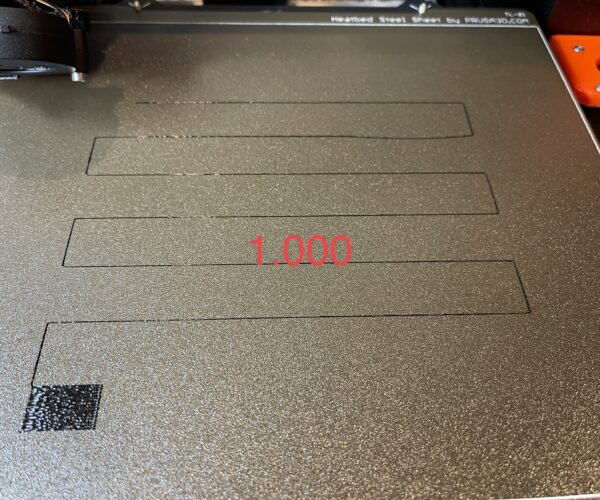

On my first layer, I get what appears to be the nozzle dragging into the print. I have the Z offset at -1.3 (I realize this is printer dependent) but if I raise the tip then the filament doesnt stick, if I lower it I end up with this dragging as seen below. I have tried 2 different brand new Prusament PETG filaments straight from the bag. I have done a full re-calibration 3 times. I have the pinda set to exactly 1mm using the ziptie method as well as a printed adjuster (PLA prints great BTW). I have cleaned the top, I did a cold pull to make sure everything was clean inside. Any advice would be greatly appreciated.

RE: Prusament PETG help

the Prusa First layer calibration tool id not particularly easy to use I prefer

Life Adjust'Z' My Way (By Jeff Jordan)

there are test square files in a zipfile at the bottom of the first post.

with these files you get a longer print time to adjust your settings correctly

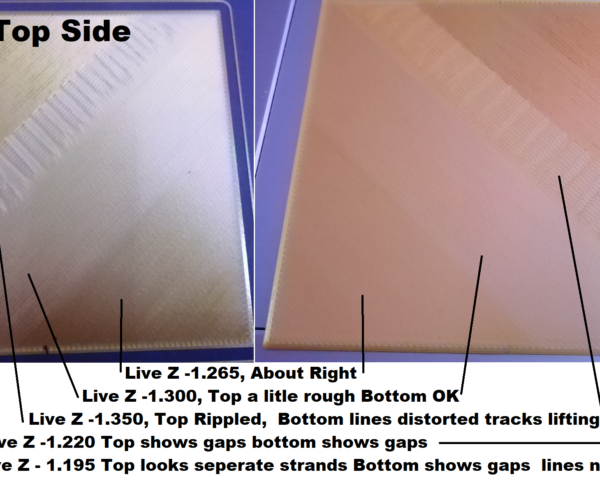

the images above are unique to my printer, and printed on a smooth sheet,

the situation is similar on a textures build plate. they demonstrate the small variations in live Z value that make significant differences in the surface finish.

please remember that you can alter the live z value whilst the printer is printing, to adjust the quality of your first layer to the best possible values

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Prusament PETG help

@tekjunke

People have very different experience with their textured sheet, some say they are great, some say they are garbage!

Prusa seems to have more than one supplier of the textured sheet so they behave differently depending on where they come from. That the conclusion I have made reading all the threads about people struggling with their textured sheet and PETG.

I notice your sheet is marked "TL-21", I don't know if that number has something to do with supplier, different supplier has different number, or different batches has different number.

However, what I do know is that my textured sheet is marked "TL-21", and I struggle with it so much in the beginning, could not use it to print petg. Almost gave up on it. In the end I have two alternatives, throw it, or (against Prusas recommendations!!) clean it _thoroughly_ with dishsoap and water, hot water, lots of hot water, more then once, dry with paper towel, and immediately on the heated bed to get it really dry, 10min on each side.

Never had a problem since 👍

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: Prusament PETG help

@ringarn67

I had the same issue and a thorough scrub with dawn platinum and hot water worked great. I even hit it with 99% IPA after drying just for for kicks. PETG and TPU stick to it great. That part you are printing I've had a number of issues with. In my experience the first layer needs to be extra slow to get those small parts of the lettering to go down well.

RE: Prusament PETG help

I'm of the opinion you are not low enough yet. All of those patches are showing adhesion issues. The picture with the torn up patch is probably a fingerprint coupled with Z too high. Every one of those pictures is not smooth, exhibiting curlies (too high). I print PETG most of the time (daily) and what you should see is a smooth sheet with almost no visible lines.

Adjusting Z is only begun when you set pinda height and set your initial Z. Be prepared to live-z adjust any time - and if your textured sheet is new, you'll probably have issues (it's a slippery devil). You need to be closer when you on the textured sheet because the surface is irregular - dips and hills. Adjusting Z for just the hills doesn't get you adhesion on the dips.

RE: Prusament PETG help

Thanks for all the replies an advice.

I think I got to the bottom of the problem, when I set the super pinda height, I "think" I had the steel sheet in place. I reset it without the steel sheet, using a zip-tie that measured 1.16mm, did a fully XYZ calibration then set the live adjust Z to slightly lower that I thought it should (with textured sheet) and BINGO, perfect first layer.

RE: Prusament PETG help

@tekjunke

I believe there are profiles for different beds, in which you can set each profile a Live Z, when you change beds just use the other profile.

https://help.prusa3d.com/en/article/steel-sheet-profiles_1955/

Glad to hear you've fixed it!