Problems with Tunning, Printing , adhesion, over all mess.

Greetings,

I have a Prusa MK3S, I have had it for about 2 years now, and havent used it much, I have restarted printing a few things, short version, its a HINGE for a Card Clock.

I was able to print 60 of the 77 I need, however, I changed my nozzle, from the brass supplied, to a hardend steel. as Well I ran out of of my PETG spool, so I had to change that as well

since having to do this, I am cant seem to print a successful hinge to save my life.

- I have reset the wizard and re-calibrated.

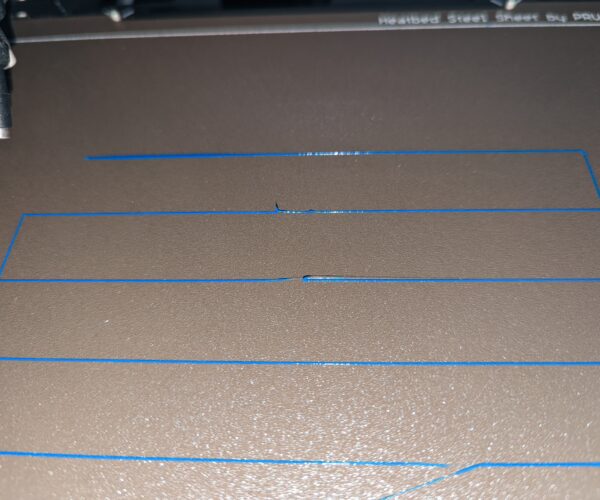

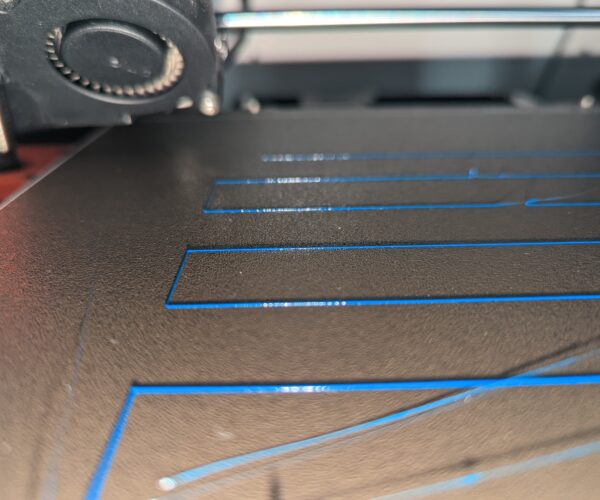

- I have re-calebrated the first layer setting about a 100 times.

It seems to print the extrusion test layer pretty good, but when it does the calibration, its hit or miss.

but when it prints the hinge , it seems to get hung up in the nozzle,

I am looking for some calibration help or someone to point me to a video that will help.

I have to take a break every mins or so. or I am going to rip my ears off.

even when it was successful in the past, I struggle to print multiple copies of the hinge.

I was able to print 60 or so hinges, 1 at a time, when I tried to print 2, fails everytime.

I suspect its all calibration, but I dont know anymore.

I would love some insight.

RE: Problems with Tunning, Printing , adhesion, over all mess.

Did you try adjusting your print temperature? Hardened steel has a different profile than brass. When I played with a Nozzle X I had to adjust all my profiles up about 10 degrees or so. I'm now using tungsten carbide, which doesn't require any adjustments.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/