Problems with Second and Third Layers?

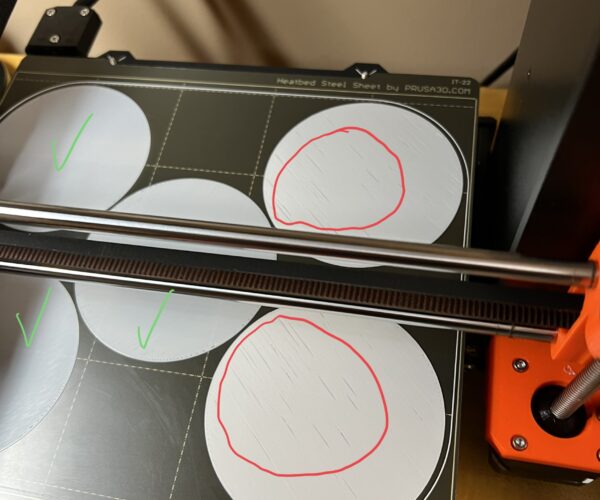

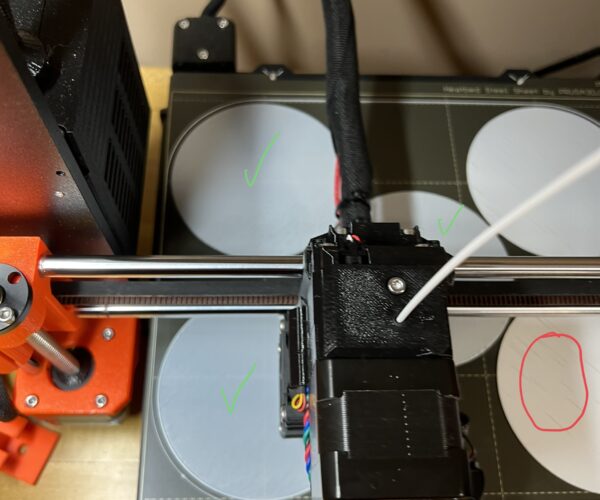

I’m printing drink coasters. Looking at my photos I think I have a good first layer. (Fell free to correct me if I’m wrong.) My problems started happening on my second layer and continued through my third. The fourth layer and above look better, but I wouldn’t call them perfect.

As you can see in the photo it appears as if my second layer is my first and I have my Z too low, however this is not the first, it’s the second. I originally thought since the print speed was faster on the second layer maybe the extruder tensioner not set correctly? But layers four through seven are printing fine.

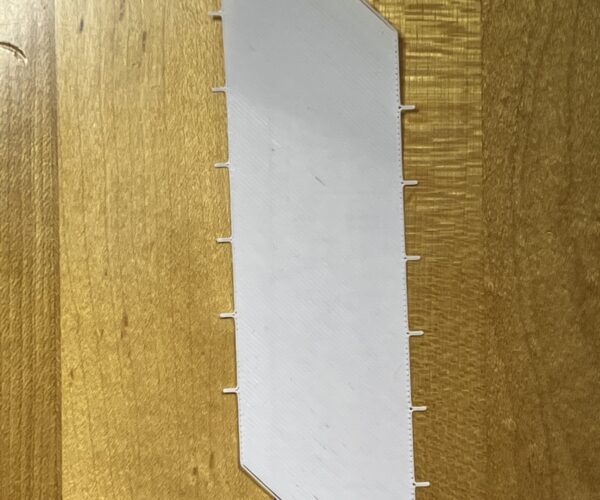

Just to double check myself I printed the large calibration strip to set my new Z. My Z is set to the value you see in the middle of the strip. Is it too low?

Green is first layer, red is second.

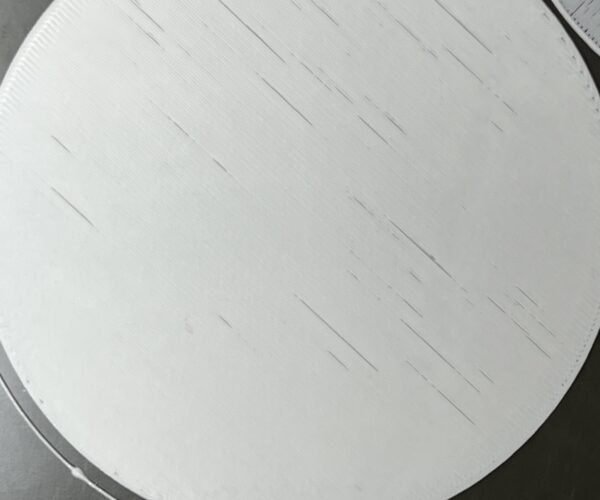

Closeup of second layer.

Large calibration print. I used the value that’s about in the middle of this strip.

Mini+MK3S+XL 5 Tool

I'd be more inclined to suspect the filament, white is always tricky; does the issue persist with a different colour?

If so, and if you must use white, try increasing the temperature by a few degrees. Slowing the print might help as well.

Cheerio,

RE: Problems with Second and Third Layers?

That’s something I haven’t thought of, but you are right. I’ve seen some strange things with white that I never expected.

Let me experiment and I’ll get back to you.

Mini+MK3S+XL 5 Tool

RE: Problems with Second and Third Layers?

Funnily enough one of todays articles on HAD was on the problems with white filaments. https://hackaday.com/2022/12/06/psa-watch-out-for-white-filament/

But yeah white has often been problematic. Even without the sometimes abrasive colour which I dont worry about (steel nozzle X) its the particle size that can cause partial clogs.

RE: Problems with Second and Third Layers?

Wow, that’s interesting. Unfortunately I have to use white for this project because it’s supposed to be an ice surface. Might be interesting to note that image is from my Mini+. My MK3S+ is only a month old so I’m confident it’s not the nozzle, and everything else printed on it looks great.

So far I’ve printed 140 of these things, most of them were two at a time on my Mini. 🤯 I recently changed my filament, I started with “Made for Prusa PLA” but due to a miscalculation on my part I ran out and the images in this post are from Polymaker PLA. While I did notice this when I still had Made for Prusa, it wasn’t as noticeable as these photos. This is my first time using Polymaker, so I’ll play around with speed and temp. 😉👍

Mini+MK3S+XL 5 Tool

RE: Problems with Second and Third Layers?

Wow, that’s interesting. Unfortunately I have to use white for this project because it’s supposed to be an ice surface. Might be interesting to note that image is from my Mini+. My MK3S+ is only a month old so I’m confident it’s not the nozzle, and everything else printed on it looks great.

So far I’ve printed 140 of these things, most of them were two at a time on my Mini. 🤯 I recently changed my filament, I started with “Made for Prusa PLA” but due to a miscalculation on my part I ran out and the images in this post are from Polymaker PLA. While I did notice this when I still had Made for Prusa, it wasn’t as noticeable as these photos. This is my first time using Polymaker, so I’ll play around with speed and temp. 😉👍

Great to know as Prusa 3D printers are highly reliable machines and can produce excellent parts right out of the box. Priced just under $1,000, the MK3S+ offers a very good price-to-performance ratio. With its open chassis and customizable “everything”, it's a great option for those that like to get manual.

RE: Problems with Second and Third Layers?

I can recommend white Verbatim PLA, I use it quite a lot...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!