Problem with the steel plate

Whenever I print e.g. ASA on the coated steel plate, it does not stick to the plate.

Best Answer by Zoltan:

Can you show us (picture) please the result of your first layer calibration and let us know what Firmware release do you have installed?

The textured sheet requies lower Z live set calibration. If you have FW 3.8.0 and higher you can have 8 different "sheet profiles" with different z live calibration.

Usual Z level for smooth is about -560 to - 600 for the textured (coated ) is between -700 to -800.

So if you changed the smoot sheet by the coated you have to recalibrate the live Z.

Thanks Lars Bo Wassini

RE: Problem with the steel plate

Start with a really clean sheet that has been scrubbed with unscented dish detergent and water.

Print a Live Z calibration square, 2" or so in size. Make sure the Z is correct. Post your result here.

I don't know if ASA needs any special treatment - like glue stick - but your Z looks high to me.

RE: Problem with the steel plate

@wassini

re "unscented dish detergent" from @robert-rmm200

try the 'Frosch' window-cleaner; a quick google said that this should be available in Denmark.

If not: do yourself a favor and buy *the cheapest one*, e.g. the brand you would never use to clean dishes or windows 'cos its too harsh to your skin.

-> The stuff they put in "to be nice to the skin" (some oil, aloe vera, whatever) is exactly what prevents the filament-stickage.

BUT (read in the voice of Tyrion Targaryen):

-) a proper Z-Calibration (the pics in the manual are really ...non-optimal...) is still needed

-) maybe your printer is simply going too fast (dial down the speed with the knob after the calibration-song-and-dance)

-) do the samples (included on the SD-card, the PRUSA-Logo prints in 20 minutes) work?

all the best & have a nice weekend

RE: Problem with the steel plate

Can you show us (picture) please the result of your first layer calibration and let us know what Firmware release do you have installed?

The textured sheet requies lower Z live set calibration. If you have FW 3.8.0 and higher you can have 8 different "sheet profiles" with different z live calibration.

Usual Z level for smooth is about -560 to - 600 for the textured (coated ) is between -700 to -800.

So if you changed the smoot sheet by the coated you have to recalibrate the live Z.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problem with the steel plate

So many people seem to have issues or just don't know what a good first layer should be. I decided to made a video today showing how to adjust the live Z to get a good first layer. Hope this helps.

https://www.prusaprinters.org/prints/20306-first-layer-calibration

RE: Problem with the steel plate

Prusa must have had Bang-up post-Christmas sales. A lot of new folks joining.

Most of the people posting start with "I got my MK3S kit yesterday and just finished it.

Nothing sticks to my build plate - the Ender 3 is better".

They seem unwilling to take the time to either build the kit carefully or learn what is required to be successful printing.

Hopefully, with time will come wisdom. Or there is always that Ender 3.

RE: Problem with the steel plate

It's hard to wait when you get a new toy! Use now ask later! 🙂

RE: Problem with the steel plate

Hi @wassini

did you manage to set up your first layer?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problem with the steel plate

[...] Hopefully, with time will come wisdom. Or there is always that Ender 3.

Things aren't much better in the various 3D printing reddit groups. While the Prusa Live-Z procedure can be a bit mysterious, it's nowhere near as bad as what the poor folks with only manual bed leveling wind up with. At least is stays level even if you use the printer.

The BuildTak-like surface on those printers tends to grip no matter what, so you see a lot of prints with very badly leveled beds, followed by frustrations getting glass or other work-arounds to work.

Whenever I see those complaints, I can only suggest they spend time in those other groups and realize that mastering anything as complex as current consumer-grade FFF printing takes a bit of time, but is time well spent.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Problem with the steel plate

@zoltan

Yes - adjusting the Z level helped a lot. Now I only have another problem. The ASA gets stuck inside the heat element after a few minutes of printing.

But I'll create another thread for that.

Thanks Lars Bo Wassini

RE: Problem with the steel plate

So many people seem to have issues or just don't know what a good first layer should be. I decided to made a video today showing how to adjust the live Z to get a good first layer. Hope this helps.

https://www.prusaprinters.org/prints/20306-first-layer-calibration

First tell the firmware which sheet you have mounted (smooth or textured) the last Z setting you set will be stored by the firmware for that sheet.

You need to repeat this process for each different sheet type you use. The physical thickness of the textured sheet is thinner than the smooth sheet.

Never ever mislead the firmware about which sheet is current. That can dig trenches across the sheet - or print in the air.

Thanks @robert-rmm200

RE: Problem with the steel plate

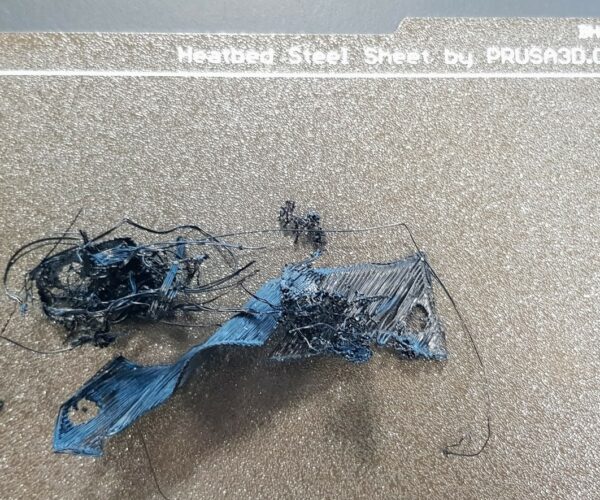

Using plain "Heatbed steel sheet"

I hade the same but opposite problem.

I made several prints with PLA, no problem.

Changed to ASA hade some minor problems with warping (very big part).

Changed back to PLA, CATASTROPHIC !!! no adesion to steel plate.

Some fast cleaning with aceton

Slightly better, but still very bad.

Very good cleaning with acetone.

OK but not as before .....

I am a chemist and have been working with surfactants, how chemicals i minute traces adhere to surfaces. This seems to be the problem ....

Even very small amounts of some chemicals in the ASA can have a devastating effect on the next filament (if it is PLA azure blue in my case).

It might be the same problem in your case.

Problem can also be how to clean the nozzle.