Problem with Support

Hi,

i hope someone can help me with my problem.

First my data:

Printer: Mk3 preassabled

Firmware: 3.3.0

Software: Win 1.40.0

So now the problem:

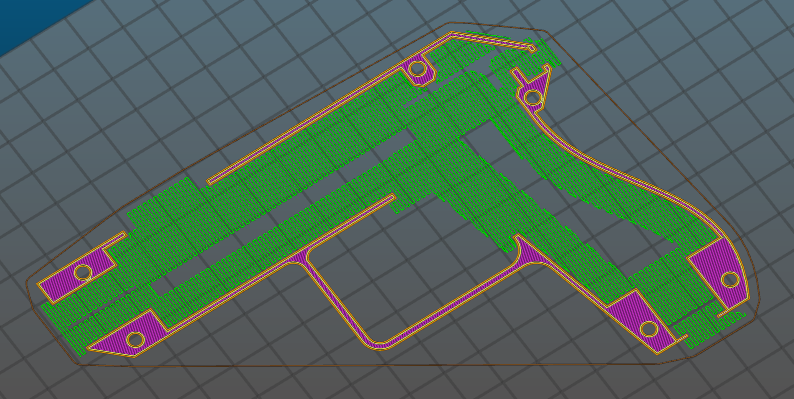

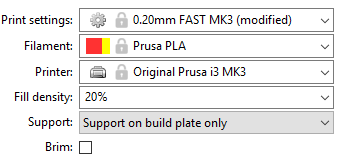

I have a print with support:

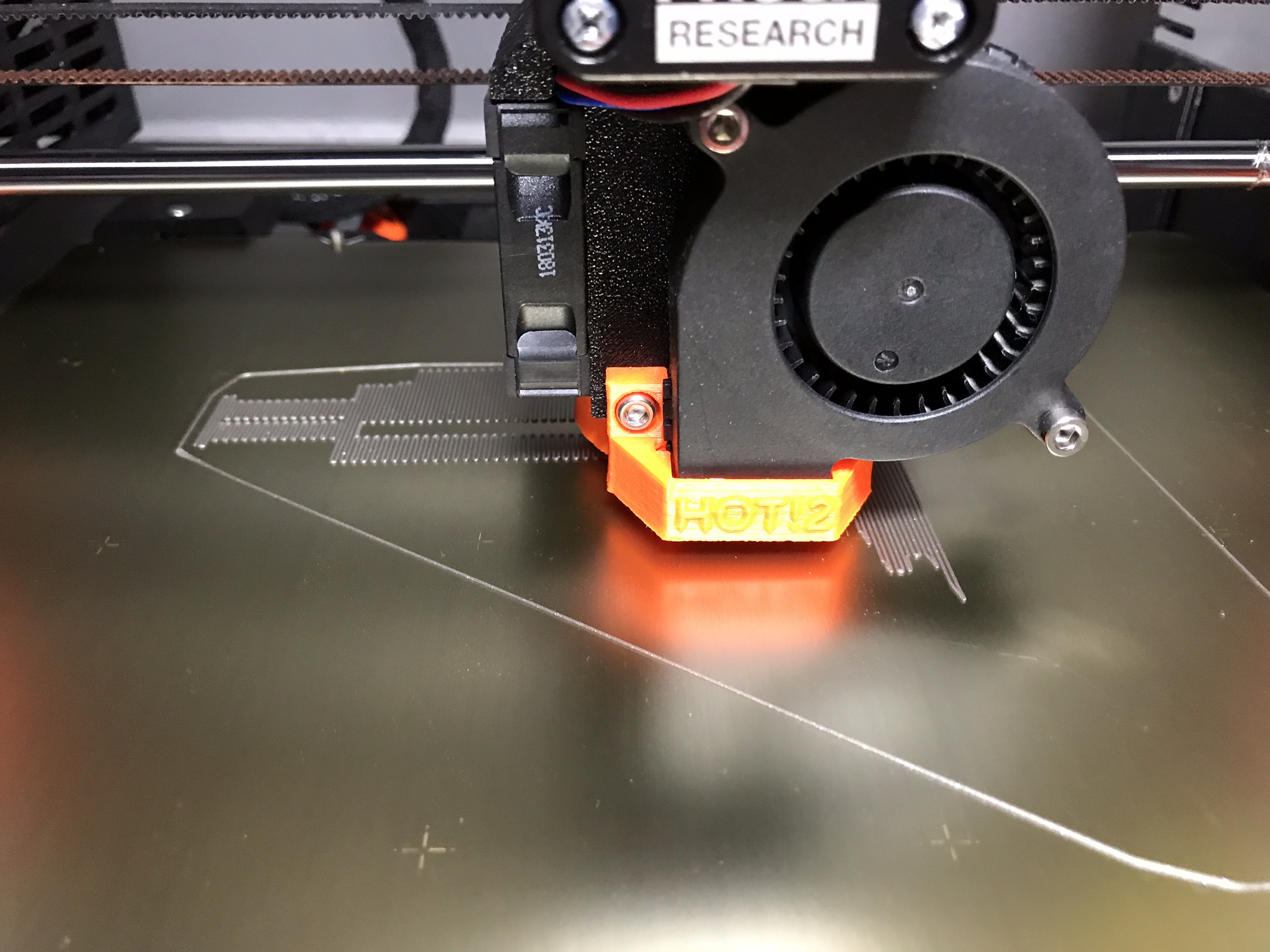

When i start to print this model i get this bad first layer result:

Here the settings:

The same with the 0.15 Settings.

What is the problem? 🙁

Re: Problem with Support

Is your nozzle free of debris, and did you clean bed with isopropyl alcohol?

Re: Problem with Support

Looks like you need to adjust your Z height. See pages 24-26 of the manual.

Doing my thing from my little corner of the world.

Re: Problem with Support

In addition to the 1st layer, SLOW IT DOWN. I find that detailed dense support is really touchy, and any sort of disruption will result in it peeling off the bed. To test, when your print starts, simply dial speeds back using the front knob. I'd suggest go back to 50% and see if the filament starts laying down consistently. Once it does, you can start adjusting speeds upwards.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Problem with Support

Is your nozzle free of debris, and did you clean bed with isopropyl alcohol?

Yes i clean the bed every time bevor a print with 99,9% isopropyl.

The nozzle is also free of debris:

Looks like you need to adjust your Z height. See pages 24-26 of the manual.

I bought the printer fully assembled. So i hope the calibration must be fine!?

Re: Problem with Support

In addition to the 1st layer, SLOW IT DOWN. I find that detailed dense support is really touchy, and any sort of disruption will result in it peeling off the bed. To test, when your print starts, simply dial speeds back using the front knob. I'd suggest go back to 50% and see if the filament starts laying down consistently. Once it does, you can start adjusting speeds upwards.

Ok i will test it maybe with 35% and give you a feedback 🙂

Re: Problem with Support

In addition to the 1st layer, SLOW IT DOWN. I find that detailed dense support is really touchy, and any sort of disruption will result in it peeling off the bed. To test, when your print starts, simply dial speeds back using the front knob. I'd suggest go back to 50% and see if the filament starts laying down consistently. Once it does, you can start adjusting speeds upwards.

Ok i will test it maybe with 35% and give you a feedback 🙂

Ok in the first minutes the result looks better. bevor i scaled down to 70% and it was the same problem... now i tryed with 35% and the result looks like this:

Re: Problem with Support

Even if the printer is pre-assembled, you really should to Live-Z adjustment. It can vary depending on filament type and any nozzle changes or other adjustments you've made.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Problem with Support

I bought the printer fully assembled. So i hope the calibration must be fine!?

Recalibration is necessary even after moving the printer carefully, for instance in your own car. I doubt the factory calibration is going to survive transport by parcel carrier.

Re: Problem with Support

Thank you for all your help.

Another problem solves my issues with the support.

It was the same issue like this one: https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/first-layer-frustrations-t19004-s20.html

So the Topic can be closed 😉