Re: Problem with Prusa Petg and Slicer PE

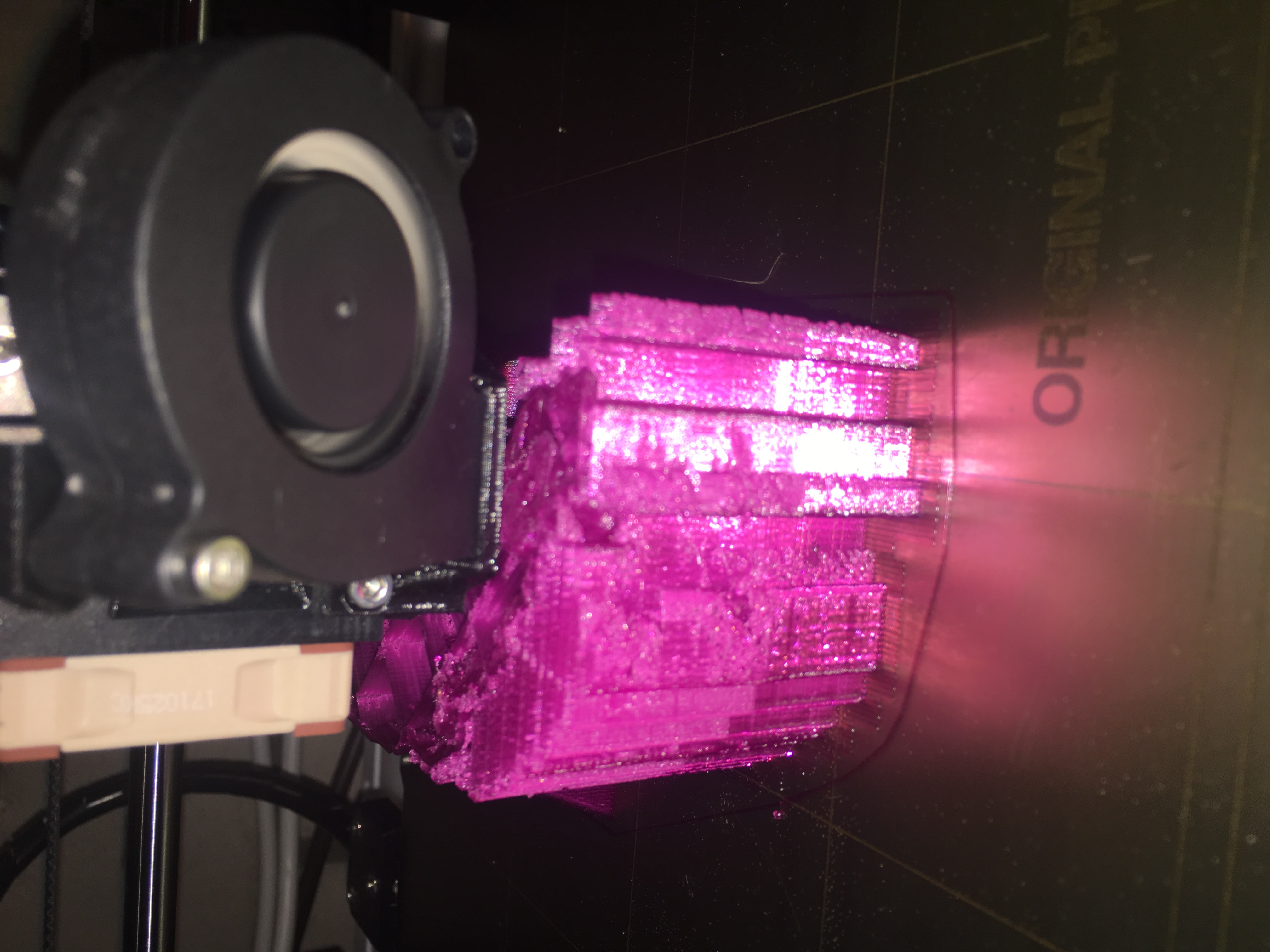

looks like its starting to air-print and jam. search how to do a cold-pull and further hotend maintenance if needed.

Re: Problem with Prusa Petg and Slicer PE

I dont think that. Because with other Petg I don't have this problem. Just with prusa filament.

Bad roll?

Re: Problem with Prusa Petg and Slicer PE

That’s PLA, not PETG. Right? Prusa only sells PETG in jet black and orange. That looks like Ms. Pink. PLA.

When someone asks you if you're a god, you say, "YES!"

Re: Problem with Prusa Petg and Slicer PE

That’s PLA, not PETG. Right? Prusa only sells PETG in jet black and orange. That looks like Ms. Pink. PLA.

Not entirely true, they also sell PETG in other colors like green and blue. But you are right, they don't sell pink.

Which filament settings did you use?

Re: Problem with Prusa Petg and Slicer PE

That’s PLA, not PETG. Right? Prusa only sells PETG in jet black and orange. That looks like Ms. Pink. PLA.

Not entirely true, they also sell PETG in other colors like green and blue. But you are right, they don't sell pink.

I, possibly incorrectly, inferred OP was referring to “Prusament” branded filament. But you are correct, they do sell other colors w/o the Prusament branding.

When someone asks you if you're a god, you say, "YES!"

Re: Problem with Prusa Petg and Slicer PE

Yes it was not prusament. I bought this before prusaments comes out. Now I try to print this in black with other Petg and it works.

Very strange.

Re: Problem with Prusa Petg and Slicer PE

Does the filament "feel" the same in your hand as the other PETG filament? Or is it different somehow?

Re: Problem with Prusa Petg and Slicer PE

Nope feels like the same.

Re: Problem with Prusa Petg and Slicer PE

Are there temperature specs on the spool?

That checkout clearly says PETG, but the only “transparent violet” on the site today is a PLA/PHA. I wonder if they mislabeled it when they sold it?

When someone asks you if you're a god, you say, "YES!"

Re: Problem with Prusa Petg and Slicer PE

From the pictures I am having trouble understanding what the issue is. are you saying that the infill is getting damaged by the nozzle?

if so dial back the flow rate so that it is not building up a blob on the nozzle and dragging it into the infill.