Re: Printing Issue with the surface

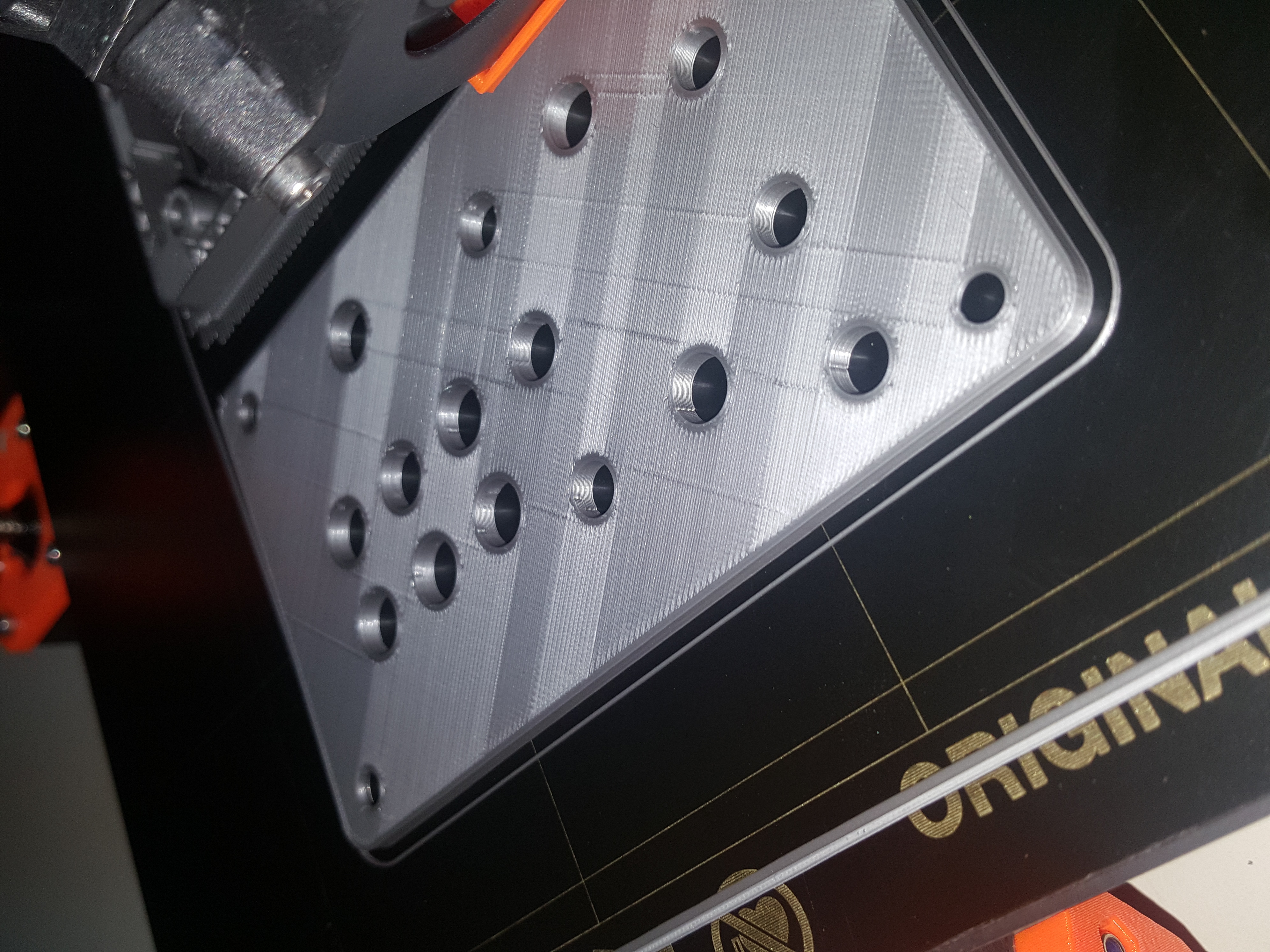

The previous layer is bleeding through. When doing infill, Slic3r moves the head along until it finds a hole, then comes back from the other direction. This leaves a single thicker line at that intersection. You can see them in your photo along each hole.

Slowing down the print speed can help. Especially the infill speed. It defaults to 200mm/s which is generally too fast. I'd start at 100mm/s, and move down from there, depending on many things... no strict formula to recommend (none I can recommend because I'm still fighting this myself).

If it's the "sheen" you are concerned about, that two tone effect, slowing infill can help that, too. Or even playing with the fan speed.

Re: Printing Issue with the surface

Try Cura, it has an "ironing" option which goes over the top layer a second time to smooth it out.

Re: Printing Issue with the surface

Or try pressing it into a heated cast iron sizzler so that the sand mould texture is transferred to the surface of the print.

(Do this at your own risk, as I will nor be responsible for burnt fingers!)

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Printing Issue with the surface

> Try Cura, it has an "ironing" option which goes over the top layer a second time to smooth it out.

I created an ironing process for slic3rPE, the pull request is currently on hold.

If you want to stay on slic3rPE and test, it you can download my fork here ( https://github.com/supermerill/Slic3r/releases ). Please report back to see if it's worth adding, (and if it's better/worst than the cura one)