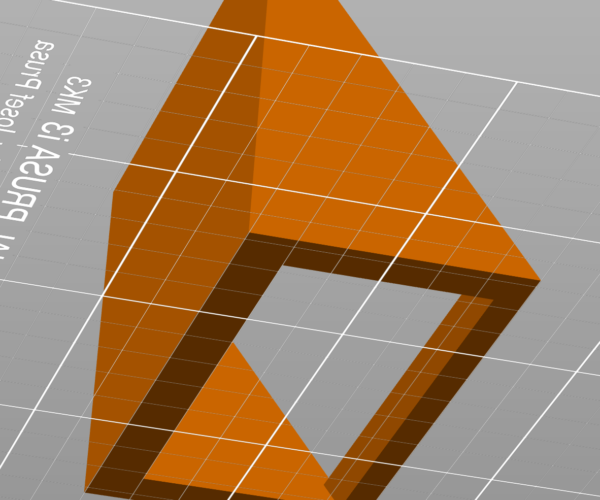

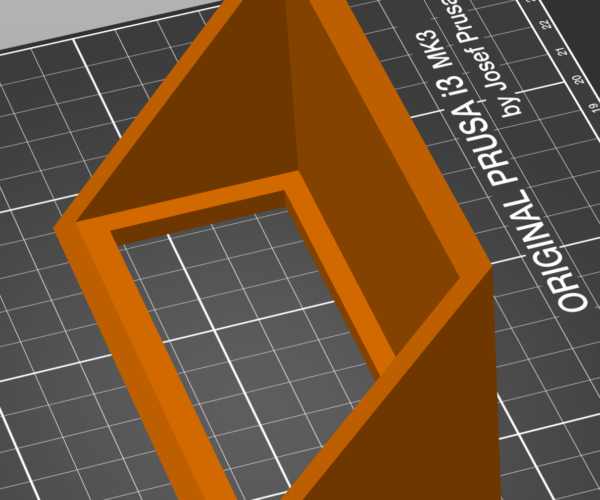

Printed Item Bows on Corners

I have designed a part in F360 and it is square when drawn. As the part is being made, the corners start to bow upward off the build plate. PLA, .15 layers 15% infill. Does great until about 50% complete then it starts. Any ideas? No cold air issues, room temp is steady. PLA stored with dessicant pack.

RE: Printed Item Bows on Corners

I think this is a pretty standard issue. I think solutions include:

Use a brim.

Use mickey ears on the corners that you detach after printing

Use Gyroid infill pattern. @swiss_cheese told me that that cubic another infills can cause this too. I'm currently printing something where I was having the same issue and I was using cubic. I'll let you know how mine turns out.

RE: Printed Item Bows on Corners

@ssill2

Thanks for the info. I'll give these a try....

Hal

RE: Printed Item Bows on Corners

Mine did have one corner lift. oh well. might do a brim myself.

RE: Printed Item Bows on Corners

If that works for your design, you can also try to make the corners round. Short of that, a brim is probably your best bet.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printed Item Bows on Corners

That's warping. It can be caused by poor bed adhesion. Be sure the bed is thoroughly clean. I recommend dish soap and water and nothing else. Be sure your Live-Z is well calibrated. I recommend Jeff Jordan's "Life Adjust" procedure. If you're sure the basics are taken care of, you can try:

- Increase the bed temperature. PLA will deform above 70C or so, so don't go too high.

- Stabilize temperatures. You don't necessarily need an enclosure, but protect the print against breezes and temperature variations.

- Adhesion booster. I'm not crazy about these, but a bit of MagiGoo or similar can help with difficult prints.

- A brim can be added. The downsize to a brim is that it's a consistent width around the entire print, and only along the outside. It may be too much for some areas, and not enough where you really need it.

- Mouse ears can be placed on the corners and other lift-prone areas. I do this frequently with large prints that are prone to lifting due to uneven cooling. You can make them whatever shape and size you need. I find 30mmx0.2mm discs a good size for grip.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printed Item Bows on Corners

Thanks for all the responses. I changed the infill type to gyroid, added the brim and raised the bed temp to 65C. It has pretty much solved the bowing. I clean the build plate after each run with a little Dawn and warm water. The brim sheds easily after printing, so I'm going to run a couple more to be sure.

Thanks again for everyone's assistance.

Hal