Print problems with PETG

Hi all,

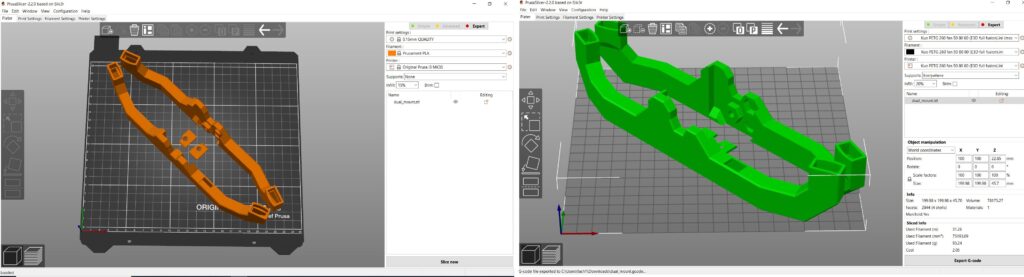

I am a bit of a nooby when it comes to printing with PETG. I am getting alot of stringing and oozing resulting in bleeding with my prints (see attached picture). I have been researching on the web but can't really find which settings I should change in Prusa Slicer or where I can find them. At the moment I am using the standard PET settings to print it. Is anybody out here who can help me out which settings I should change to get better results?

Thanks in advance!

Dennis

RE: Print problems with PETG

First thing you should try is to lower the nozzle temperature, it would significantly resolve the stringing problem.

RE: Print problems with PETG

Yep,. I had a lot of trouble printing at first with PETG (using the AmazonBasics PETG). Lowered the temp and ensured that the filament wasn't wet. Drying is pretty simple in a electric oven. If your spool has been out, make sure you dry it. (Four hours at 60-70C - ELECTRIC OVEN ONLY - PREHEAT THAT OVEN FOR AN HOUR BEFOREHAND - does wonders) That solved some of the layer issues and stringing with me. With most of your stringing problems, petg, tpu, tpe, adjusting down by 5 degrees as you print and watching the difference and adjusting more as necessary is the best way to fine-tune. Then you can create your custom filament settings for that specific brand of filament (save-as in the filament profile).

For particularly problematic stringing, I've made sure the fan was on full after the first layer - and slowed the print down a little bit, to allow that fan to do its work. You want to strike a fine balance between cooling the petg too much (then layer adhesion suffers) and not enough - too much flow, uneven layers with air movement in the room and stringing. But once you dial it in, you want to print everything in it! Keep at it.

As an aside, make sure you adjust your z a teeny bit up (you can find a good setting somewhere on here - can't remember how much offhand). You don't need to "squish" the first layer with petg like pla and if you do, that sh%$ sticks to the nozzle and give you added boogers and stringing. throughout your print. Once I adjusted my height a bit, I no longer needed to pause the print to snip off an offending string or booger with nail clippers.

RE: Print problems with PETG

Sorry to barge in on your post but I'm about to print with PETG for the first time myself.

As far as Prusa Slicer goes, when you select Prusament PETG from the list, it looks to me like the only settings that change are the temperatures, etc under the "filament settings".

The speed and retraction settings under "printer settings" and "print settings" don't seem to change.

Is that right? Am I supposed to change those myself?

RE: Print problems with PETG

As far as retraction settings go, leave them alone for now. The default petg prusament settings work well for other petg brands. Dial in your temp first. You can live adjust on your first print test (look for a stringing test model). Lower temp gradually (during print - live adjust) a few degrees at a time until less stringing. Honestly there's almost always at least a whisper of stringing with Petg. Your temps might need to change with the seasons unless you have a enclosure/ partial enclosure. You should get decent results with the prusa slicer presets.

RE: Print problems with PETG

I've printed only a few PETG brands, but the default settings work quite well. Prusa PETG needed a bit higher temps for good interlayer adhesion, but Amazon PETG is printing quite well, but wants a few degrees lower. Prusament PETG printed without any changes except a tweak to Live-Z to make it easier to get off the PEI.

RE: Print problems with PETG

Hi,

I have PETG printing problem also. This is my second real print. Let's clarify.

I am using a PET-G that says Printing temp: 200-220

This is strange, since even the Prusa Preheat LCD menu, set the starting PET temp from 230, that is over this material range.

So I decided to print 215 first layer, 210 other layers.

I saw that the PET profile in PrusaSlicer set 85° for FIRST layer, and 90° for the other.

- Why this ?

I would expect for PET the same logic of PLA, the first layer with higher bed temp to improve the adherence, and a lower temp for the others. Anyone knows why ?

On printing, I experienced after one hour of print the same clog issue I had times ago with PLA.

- No PETG come out from the nozzle.

- I noticed that I had the extruder click of death.

- The filament was consumed in powder at the point of the extruder grinder.

- The print looked like its started to extrude less and less material.

- I aborted the print, (keeping the nozzle high temp) and opened the extruder, door, and saw the filament consumed.

- I removed it manually, and it comes out normally.

- I pushed manually it inside, and manually I could extrude the PETG filament... (mmmhhh nozzle not clogged ?)

The impression was that :

- The filament was extremely dense to extrude

- The low temperature may have increased the issue

- Since my filament is so dense, there is no way to print infill and perimeters at 80 mm/s 😧

- The filament is so dense that when the extruder motor (that by the way, was very hot, 72°) tried to extrude it, there was a big effort, that caused the motor to overheat, and since the filament was slow to be extruded, the grind mechanism made power instead of moving it.

- Seriously, are the standard PrusaSlicer speed settings (I used 0.15 quality) realistic ?

I re-sliced everything from 0.15mm to 0.20mm, and reprinted it.

- On the second print, when I heard again the first click, I lowered the 100% value on the LCD to 60%, and increase manually the temp from 210 to 220, and since then, it was able to complete the print.

I think the PrusaSliced parameters work well for very fluid PLA, but with dense materials like PET-G or Flex, they need to be reviewed.

- What are your speed settings for PET-G ?

I will check the REAL E calibration. Even if my printer was a PRUSA Assembled, I will check to ensure the printer is extruding the correct filament length, and I will check the PET diameter is at least an average of 1.75.

Regards

RE: Print problems with PETG

I print primarily PETG and polycarbonate. Your mentioned PETG nozzle temperatures are super low.

Attached is a zip archive with my PETG print, filament and printer settings.

filament Kuo PETG 240 fan 50 80 80 (E3D for stringy brands).ini Kuo PETG 245 fan 50 80 80 (E3D standard).ini Kuo PETG 260 fan 50 80 80 (E3D full fusion).ini print Kuo PETG 0.15 3Perim 4TopBot.ini Kuo PETG 0.15 4Perim 5TopBot supports.ini Kuo PETG 0.15 4Perim 5TopBot.ini printer Kuo N7 R1 startup.ini

You can import them into PrusaSlicer to use them. Be sure to get all three types of settings imported and selected (Print, Filament, Printer)

These settings work well in my systems for a wide variety of PETG including AmazonBasics, Prusament, StrongHero, Paramount, and Overture.

Caveats learned the hard way here....

When switching from one type of filament to another, remove all residuals from printing other plastic from your nozzle and print surface. The nozzle can be cleaned by running a dozen or so cm of cleaning filament through the extruder (at higher melt temp of the two filaments you are switching between). Alcohol wipe down is insufficient for 1st cleaning between different plastics. Wash once with with a Dawn dish soap. Thereafter, alcohol wipe is sufficient.

If PETG isn't sticking 1st layer, your print plate needs to be washed. <<<

All the PETG's benefit from drying. If you don't have a filament dryer, you are simply missing an essential tool. Really not much excuse to skip drying if you are serious about having good quality, consistent print results. A simple $110 food dehydrator works perfectly. https://www.amazon.com/gp/product/B01M6AZ863

Some brands of PETG are stringier even after drying (ColorMe3D, Stronghero). For those, I use profiles with slightly lower nozzle temperature. Other brands are amazingly consistent with my profiles (Paramount, AmazonBasics, Overture) and can even go to higher temps for maximal layer fusion.

RE: Print problems with PETG

@antimix

The post that keeps on giving. I was having problems with Overture PETG leaving detached threads on the inside of radiuses. Simple temperature increases, like those in...

Kuo PETG 260 fan 50 80 80 (E3D full fusion).ini

... solved my problem. Thank you!

RE: Print problems with PETG

@guy-k2

Thank you! I am rockie on this, and your files fix my issues. I am new in printing and still learning about the fine tune-up settings. Your settings help to solve my problems. I have a rockie question; after I load your ini file, my bed size change. I know the bed changed the size because it is not room to moved or add something. How can I fix this? Thank you.

RE: Print problems with PETG

I print primarily PETG and polycarbonate. Your mentioned PETG nozzle temperatures are super low.

Attached is a zip archive with my PETG print, filament and printer settings.

filament Kuo PETG 240 fan 50 80 80 (E3D for stringy brands).ini Kuo PETG 245 fan 50 80 80 (E3D standard).ini Kuo PETG 260 fan 50 80 80 (E3D full fusion).ini print Kuo PETG 0.15 3Perim 4TopBot.ini Kuo PETG 0.15 4Perim 5TopBot supports.ini Kuo PETG 0.15 4Perim 5TopBot.ini printer Kuo N7 R1 startup.ini

You can import them into PrusaSlicer to use them. Be sure to get all three types of settings imported and selected (Print, Filament, Printer)

These settings work well in my systems for a wide variety of PETG including AmazonBasics, Prusament, StrongHero, Paramount, and Overture.

Caveats learned the hard way here....

When switching from one type of filament to another, remove all residuals from printing other plastic from your nozzle and print surface. The nozzle can be cleaned by running a dozen or so cm of cleaning filament through the extruder (at higher melt temp of the two filaments you are switching between). Alcohol wipe down is insufficient for 1st cleaning between different plastics. Wash once with with a Dawn dish soap. Thereafter, alcohol wipe is sufficient.

If PETG isn't sticking 1st layer, your print plate needs to be washed. <<<

All the PETG's benefit from drying. If you don't have a filament dryer, you are simply missing an essential tool. Really not much excuse to skip drying if you are serious about having good quality, consistent print results. A simple $110 food dehydrator works perfectly. https://www.amazon.com/gp/product/B01M6AZ863

Some brands of PETG are stringier even after drying (ColorMe3D, Stronghero). For those, I use profiles with slightly lower nozzle temperature. Other brands are amazingly consistent with my profiles (Paramount, AmazonBasics, Overture) and can even go to higher temps for maximal layer fusion.

Attachment removed

Hi bunny science,

I will try your settings because I have some problems with PETG.

Do I just need to upload all the files using 'Import config" features?

It feels weird because I have all the settings in every dropdown list so I'm not sure what I need to choose as options.

Thank you

RE: Print problems with PETG

can you please upload your setting again?