PLA print pulling up on one side

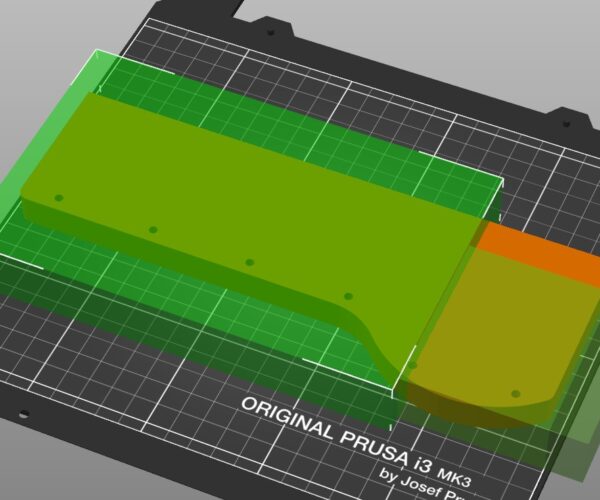

Super newb here. This is my first week of printing ever. Using a MK3S+ I just finished building. I've printed 4-5 things so far and they all just worked with no tweaking necessary. I was really pleasantly surprised with that, I expected much more trouble in my first efforts. Those parts were all smaller and fit in the center 1/3 of the bed. This next part is pretty much full width. I didn't want to dive right into a many-hour print without first testing that my clearances are ok on my over-printed nuts. So I added some negative volumes to print only the one corner of it as seen below

The first go went terribly. It started out fine and after a few layers I thought "all good" and stopped watching. Next time I looked over the piece had broken off the bed and was being pushed around in a small ball of filament. Fortunately nothing bad to clean up.

I started the same print again and this time watched it closely. After a few layers, all of which seemed stuck to the bed, the print fan kicked on. Shortly after this the right edge (evenly from front to rear) started to lift. I stopped the print.

Then I went into Prusa slicer and raised the bed temps from 60 to 65 as well as disabled the print fan until layer 5. I then had it taper in from layer 5 to 15. The thinking behind both of these changes was just to make sure those lower layers were plenty hot to stick properly. Right/wrong? I also manually set the bed temp to 65 and let it preheat for 10 minutes. I thought perhaps since I'm close to the edge of the bed it might need more time to come up to temp.

As another test, I used my IR temp gun (which I know Prusa says is not accurate for bed measurements) and the temps within all 20 squares on the sheet were within a 5 degree range. It was measuring about 5 degrees less than what I had it set to. For example, when the printer was set to 60, temps measured 53-56. When set to 65, they measured 56-60.

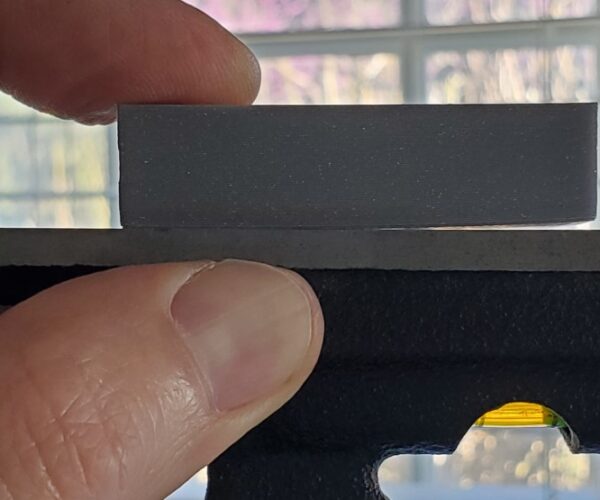

This seemed to work better, and for the first 10-15 layers I couldn't really tell that it was lifting. But by the end, there was definitely a gap again. The print completed, but the part, which is supposed to be 14.0 thick (Z) tapers down to 13.7mm in the rightmost 20mm or so.

Things I have thought to try next:

- Glue stick on the perimeter of the bed

- Add a raft

- Disable the print fan entirely

- Raise the bed temp to 70

- Surround printer with carboard to ensure no drafts

I would be really appreciative if you all could weigh in on what you'd suggest as well as the "why." I'm really wanting to understand all of this and it seems like I'm reading that warping can be from both too high and too low of temps.

Thank you!