RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Hi all,

So I did some further testing. First off, I switched back to PLA to make sure that the issue was not in the extruder. This went well and I was able to get a print out with ease. So I switched back to PETG on the PC sheet and highered the nozzle and bed temperature gradually for the first layer to 245-90. This lead to the filament actually sticking to the bed instead of the nozzle and gave a decent result. I wanted to try a print but this failed due to filament coming loose. I decided to recalibrate but i have the feeling that the nozzle is already quite close (going further from the bed makes the filament cling to the nozzle, closer i get this lumps of filament on the first layer)

What can i do more? Should I event higher the T?

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Try a different brand of filament, then you can see if it is the a bad petg roll.

Clean bed with dish soap, and do not touch with your fingers on the bed,

and see movie or pictures on the z-layer height, both are needed to get it sticking.

Clean nozzle with a brush.

Extra an normally not needed:

first layer slower,

first layer hotter,

use glue stick or hairspray to get it stick better.(bad filament?).

Check if nozzle is partially blocked, sometimes not good visible , if you change the nozzle 10 minutes work and you now if it was the nozzle.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Petg on a pei sheet, here you should use window cleaner, because it should stick to much, and destroy the pei sheet.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

@peter-m26

Some PETGs can do this but not all.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Petg on a pei sheet, here you should use window cleaner, because it should stick to much, and destroy the pei sheet.

My experience is that, if anything, PETg sticks too well, to both the smooth and textured sheets.

If, as the OP stated, PLA sticks to the sheet fine and a certain PETg does not, I would say that there's some issue with the filament and not with the sheet.

The only Prusa(ment) PETg that I have used is the orange, described as 'the stuff we use in the Farm', and again, if anything, it sticks too well.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

@jsw

True. I have a couple of brands that are difficult to stick.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Yes, it is weird certainly while using Prusament. So far the nozzle is fine and bed well cleaned. Maybe it is a bad spool, i have another PETG spool of prusament black I can try this and see if it changes anything. Sticking-wise i have no difficulty in removing all the calibration stuff, it is a bit tougher then pla but not so much more.

However i noticed that i highering the temperatures helps a bit but does not seem like an optimal solution since i think that the nozzle is very low against the bed.

Could the nozzle be jammed regardless of being able to print PLA well and what seems like a normal flow-through?

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

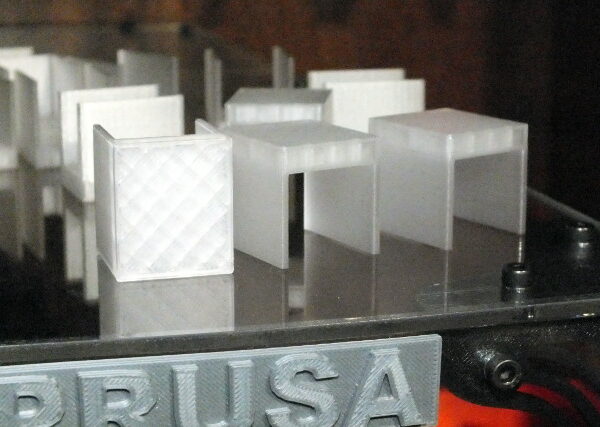

Here is a picture of the first layers of a part. I noticed that it has some small holes in it. Maybe it can help illustrate the issue.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

@alec

Make a picture of 1 layer(only 1 layer), and make the picture so we can zoom in.

See pictures in this thread how low you should go, it is important to get the z-layer 100%.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Here is a picture of the first layer, it might be a bit far. What do you guys think?

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

We gave a movie and another use gave you pictures, how to do a first layer, look at these, and look at your first layer.

You have wholes in your first layer.

And possible you need to to go lower, you need to press the filament a little in the bed, otherwise i will not stick.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

If you have a partially clogged nozzle, the line could be to thin, do not go to low if this is happening.

If you want to rule out a partially clogged nozzle, change this, is 10 minutes work.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Partial cogs can be treated several ways,

- Replace the nozzle - easiest.

- Use an acupuncture needle.

- Use a small drill bit.

- Cleaning filament.

All will have to be performed after heating the hotend.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

One other data point here for PETg on the textured sheet ...

I was printing another batch of LED diffusers (below) using so-called transparent PETg tonight.

I figured what the (heck) and decided to try it on the textured sheet, figuring if anything, the surface would give another layer of diffusion to the LED beams. I had previously done these only on the smooth sheet.

I first made sure that the plate was not only merely clean but Really Most Sincerely Clean (tm) and then applied a layer of the Layerneer Bed Weld in the center where the diffusers would be printed. I then quickly brushed off the nozzle to remove any boogers and other crud.

When I started the print, at the finish of the priming line, a very small 'string' dragged the left end of the priming line off of the plate and into the print area. Fortunately I caught it and yanked it out, and the print proceeded normally.

Lesson learned: Apply the Layerneer to the prime line area as well, just in case! I've never had this before (string pulling off the prime line) but PETg can be stringy, and this can most definitely happen.

RE: PETG Prusament + Powder Coated Steel Sheet Adhesion issue

Hi guys, sorry for the late reply.

After some tweaking I was able to get the PETG to stick. I think one of the reasons was a low ambient temperature due to the shift in seasons.

However one strange side-effect appeared, normally prusa slicer is quite accurate in printing times but now I see that they are often way off (+/- 1h difference). I don't know what the source is, might have to do with the tinkering with the settings. Any idea how to adjust this?