Outer perimeter pulls away from inside curve

I have this white "silk" PLA filament that never had good self-adhesion, but it hasn't been a problem as long as I don't try to make structural parts from it -- until today, when I used it to print on an inside curve at a 45° overhang.

When the printer lays down an outer perimeter on an inside curve that has a 45° overhang slope, the perimeter pulls away from the part at some point. Subsequent outer perimeters tend follow the first miscreant.

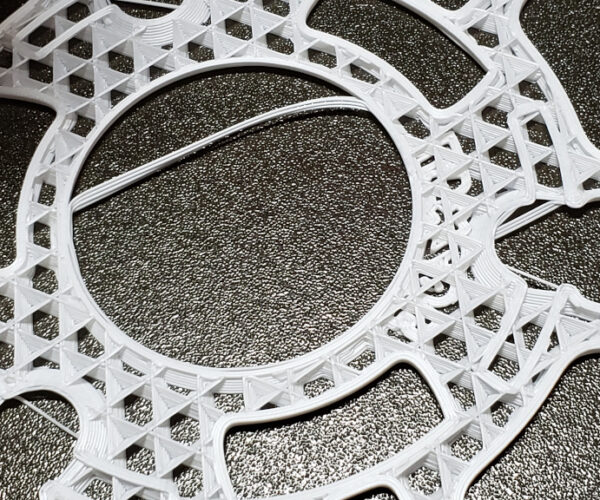

Here's an illustration. PrusaSlicer was using the stock "0.30 mm DRAFT" preset with the top and bottom surfaces set to zero layers (I thought it might improve the photograph but it didn't matter).

Every one of those stray strands is on an inside curved overhang surface (to make beveled edges).

I thought maybe the extrusion width multiplier needed adjustment for 0.30 mm layers, but the calibration test showed that the extrusion width is quite consistent, 0.56-0.58, near enough to the 0.5 default in PrusaSlicer for the 0.30 mm draft profile. In fact, I would think it should work better with a slightly wider extrusion width.

I thought perhaps the nozzle temperature was too low. I raised it to 215°C, to no avail. I could raise it further I suppose, but I suspect it won't help.

Would the fact that it's winter, and rather cool in this apartment, have anything to do with it?

What does one do with material that has poor self-adhesion?

Best Answer by Anachronist:

I printed the part with a different PLA (my standby, the 2-year-old silver-gray Prusament that came with the printer), same settings (except normal PLA temperature), and it worked fine. It's still a mystery how I would get this white silk PLA to work with that part, but I'll use the white silk PLA for something else. Material with poor self-adhesion just doesn't work if you have overhangs on an inner curved surface.

RE: Outer perimeter pulls away from inside curve

Well, based on what @fuchsr wrote in another thread, I raised the first layer temperature to 220 and subsequent layers to 225. It didn't help. The higher temperature didn't even seem to improve anything; in fact I got a few more pull-aways than in the initial picture. I am stumped.

RE:

The thing that I see immediately is the use of the textured sheet.

Those typically have more adhesion issues than smooth sheets.

If this were my print, the first thing I would try would be a good rigorous Z calibration using that sheet with that filament, using one of those multi-square test prints.

When I calibrate on a textured sheet, I'm now in the habit of 'tuning' the Z to the point that the 'brush strokes' of the bead just disappear into the texture when viewed from the bottom side of the test print.

I would then try the print using default filament parameters and change them only if there is a known specific reason to do so.

RE: Outer perimeter pulls away from inside curve

The textured sheet is not the problem, and I don't have a problem with bed adhesion because I have learned over the past two years how to deal with this textured sheet. Yes, I do what you describe, and more. I've posted my experiences with the sheet elsewhere on this forum; basically in addition to z calibration and really squishing in that first layer, I wash it in warm soapy water about every 10 prints.

I apologize for that distraction. I should have photographed a print this separation happens much higher up. I saw it happening here so I stopped the print and took the picture. The part adheres just fine to it. The first two layers were perfect.

The issue with perimeters separating occurs at any elevation. I was printing taller part with vertical sides, but when the print got up to the inside-curve overhangs, the perimeter would pull away. The picture I included just happened to show it in the first few layers.

RE: Outer perimeter pulls away from inside curve

What's the angle on the slope of those walls ? Is it the dark blue of over hang in the preview.

If you wouldn't mind saving the project (File>Save Project as) and taking the resulting .3mf file, zip it up and attach it here we could get a better idea of all the thousands of settings and variable in play.

Sometimes, slowing the print down 50% will help with this kind of a design flaw

Go slower (when printing, rotate the wheel/knob counter-clockwise for a bit and the speed will start to drop.)

RE:

What's the angle on the slope of those walls ? Is it the dark blue of over hang in the preview.

If you wouldn't mind saving the project (File>Save Project as) and taking the resulting .3mf file, zip it up and attach it here we could get a better idea of all the thousands of settings and variable in play.

The wall angle is 45°. It's just a bevel. It doesn't get identified as an overhang perimeter. The only dark blue shown in the preview are some short bridges higher up in the model.

It's my own design, so I was hesitant to upload anything as it's still a work in progress, but I've attached the 3mf. It's using stock settings with minor changes -- enabling overhand detection, disabling wipe tower, raising temperature of filament, using zero top and bottom layers, things like that -- but none of them make a difference. The same thing happens with the stock "0.30 mm DRAFT" profile that comes with PrusaSlicer.

RE: Outer perimeter pulls away from inside curve

Go slower (when printing, rotate the wheel/knob counter-clockwise for a bit and the speed will start to drop.)

That's an idea. In fact, I can set the speed of just the outer perimeters in PrusaSlicer. The default is 35mm/s. I could set it to 15. It adds more than an hour to the print duration, but understandable since the part is mostly perimeters anyway.

@anachronist

You might also try turning off, or adjusting, the "Elephants foot compensation". I can't tell for sure from your G-code but it looks like you still have the extrusion widths for the first layer set to defaults, maybe try increasing them.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE:

You might also try turning off, or adjusting, the "Elephants foot compensation". I can't tell for sure from your G-code but it looks like you still have the extrusion widths for the first layer set to defaults, maybe try increasing them.

I usually turn off elephant's foot compensation. I find that to be the most useless setting. The default extrusion width is 0.5mm for a .30mm layer height. As I said in the first post, I did the extrusion width calibration according to the Prusa knowledge base article and it came out at 0.58mm.

Also, please bear in mind that this problem has zero relevance to the first layer. The problem happens on inside curves with 45 degree overhang, regardless of height. I printed another object where the curves start about 10mm in elevation, and it happened there too. I tore the loose filaments apart to test how far the poor adhesion propagated, so there's nothing to photograph on that part. The photograph I posted, unfortunately, shows the problem near the print bed, which has proved to be a distraction that isn't relevant here. The problem is the material's poor adhesion to itself. This particular silk PLA had poor self-adhesion since I bought the spool, but other than weak parts, it didn't give me problems until just recently when I tried to print a part with an inside-curve overhang. It has worked fine on flat overhangs.

In the picture, the first two layers were perfect, as inspected with a 10X jewelers loupe. There was no separation from the bed. The perimeters separated higher up. In other prints that start out with vertical walls, when it gets to an inside curve, the perimeter sometimes separates.

What does one do when the material doesn't want to stick to itself? Raising the temperature didn't help. When the room I'm in warms up sufficiently (it's cold now) I'll try it with a slow outer perimeter speed. Maybe the nozzle coming into contact with an adjacent perimeter for a longer time might cause it to bond better with the extrusion.

RE: Outer perimeter pulls away from inside curve

Go slower (when printing, rotate the wheel/knob counter-clockwise for a bit and the speed will start to drop.)

Update: Well, I reduced the outer perimeter speed in the slicer to 15mm/sec (default is 35). That improved the situation somewhat, although there were still perimeter separations on the inside curves starting at the fourth layer. 15mm/sec is really crawling. I could go down to 5mm/sec but that changes what was originally a four-hour print into a 9-hour print.

I think I need to give up on this white silk PLA filament for this particular project. It just doesn't adhere well enough to itself (and never has). It works well for lithophanes, convex parts, or on overhangs with flat or convex surfaces. I could use it to print a thread on a screw shaft (convex curved overhangs) but not a thread in a hole (concave curved overhangs). I was hoping that this project would use up that spool, but I seem to be using it up instead on failed prints.

RE:

I printed the part with a different PLA (my standby, the 2-year-old silver-gray Prusament that came with the printer), same settings (except normal PLA temperature), and it worked fine. It's still a mystery how I would get this white silk PLA to work with that part, but I'll use the white silk PLA for something else. Material with poor self-adhesion just doesn't work if you have overhangs on an inner curved surface.

RE:

If anyone is interested in the design I was developing that started this thread, I finished it and posted it on Thingiverse here: https://www.thingiverse.com/thing:5146603

It has 45 degree overhangs on inside curves on the reel flanges and in the locking mechanism in the hub. Lesson learned: Don't print parts with such features using silk PLA.

Wow. How long to make one?

Is masterspool a safe assumption? This looks like an awesome design goal.

RE: Outer perimeter pulls away from inside curve

Is masterspool a safe assumption? This looks like an awesome design goal.

I didn't print all four designs for the four different spool sizes I found (at least those for which filament refill coils are sold). I just printed the MasterSpool. I'm not sure what you mean by "safe assumption" except maybe that MasterSpool refill coils are getting harder to find? I did find some, however.

Printing took about 3-1/2 hours per half, a bit over 7 hours of print time in total, which is quicker than for the other reusable spool designs I found. I was intrigued by the SlantSpool design using two identical halves, but I found some deficiencies in that design (like the fact that you use up a quarter of a 1kg spool just to print it), so I decided to roll my own from scratch. Because I did it in OpenSCAD, I could make it parametric and adaptable to the various refill coils I could find being sold.

RE: Outer perimeter pulls away from inside curve

Following up. The original Thingiverse link has been "disappeared" by Thingiverse. It happened when I tried to add one more STL. It's still visible to me when I'm logged in, but 404 for everyone else. So I uploaded it again. Same thing happened.

That was the last straw. I have migrated my stuff to prusaprinters. The design is now here: https://www.prusaprinters.org/prints/129989-lockspool-v3-parametric-reusable-1-part-printed-tw and I uploaded it to Thingiverse a third time, but it points you to prusaprinters for the STLs.

A few people who made this didn't report any separation of perimeters from inside overhang curves. It's just that white silk filament of mine. Fortunately the spool is nearly used up.

RE: Outer perimeter pulls away from inside curve

I have exactly the same problem (only I am using a regular gray PLA filament), meaning the problem is occurring on concave (but not convex) curves. And as you mention multiple times, it is not unique to the first layer or related to bed adhesion. I also noticed & found it interesting that in my model (which contains concave & convex curves ranging from around 3-300mm radius) all concave curves had loose or detached walls, while all convex walls were fine. For a radius difference of 3 vs 300 this is definitely worth noting.