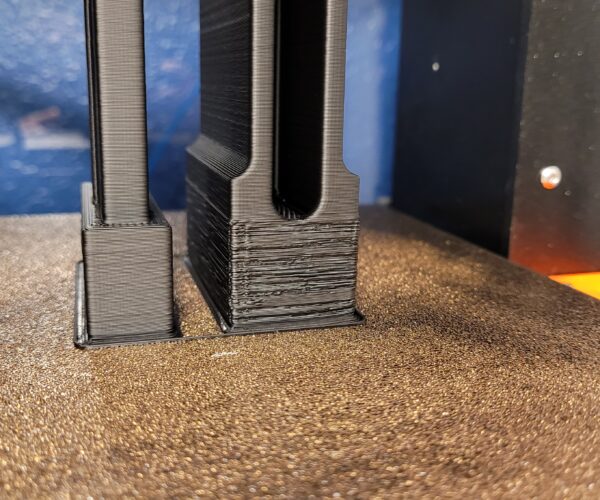

Perimeter issues

Experiencing a confusing perimeter issue. Print settings are stock prusaslicer 0.6 settings. The main difference between the two parts of this print is the part with the ugly perimeters has supports. My best guess is that that the extruder is not catching up with the flow rate from support to perimeter.

Turn off the supports?

Doesn't look like a part you would need supports to print .... um...

@feildin

Can you post a Zipped up .3mf project file exported from Slicer ?

Regards

Swiss_Cheese

The Filament Whisperer

RE: Perimeter issues

Swiss I am hoping this is the file you are mentioning. Dan, it could probably be printed without supports, but I admit I haven't got my bridging clean enough to prevent it from interfering with the intended operation of the print.

RE: Perimeter issues

Wrong file, thats the gcode file. Its the .3mf file saved from Prusa Slicer when you use File>Save Project As (Or save project if previously saved).

As Neophyl mentioned we need the .3mf, I suspect I know what the problem is, but can't be sure until I look at the settings your using in the .3mf project file.

Regards

Swiss_Cheese

The Filament Whisperer

Give this a Shot 🤣

@feildin

I made some adjustment to your project file, my suspicion is that you had to much plastic going into the area in question to fast, so I reduced the amount of plastic and slowed that specific area down to allow for more cooling time as it printing, it should still be very strong.

I could think of a couple of ways to achieve this but don't have a 0.6 nozzle in currently so I wasn't able to test.

Speed_Loader-_Body_10_Round_Swiss.Zip

Give this a Shot, let us know how it goes.

Good Luck

Swiss_Cheese

The Filament Whisperer