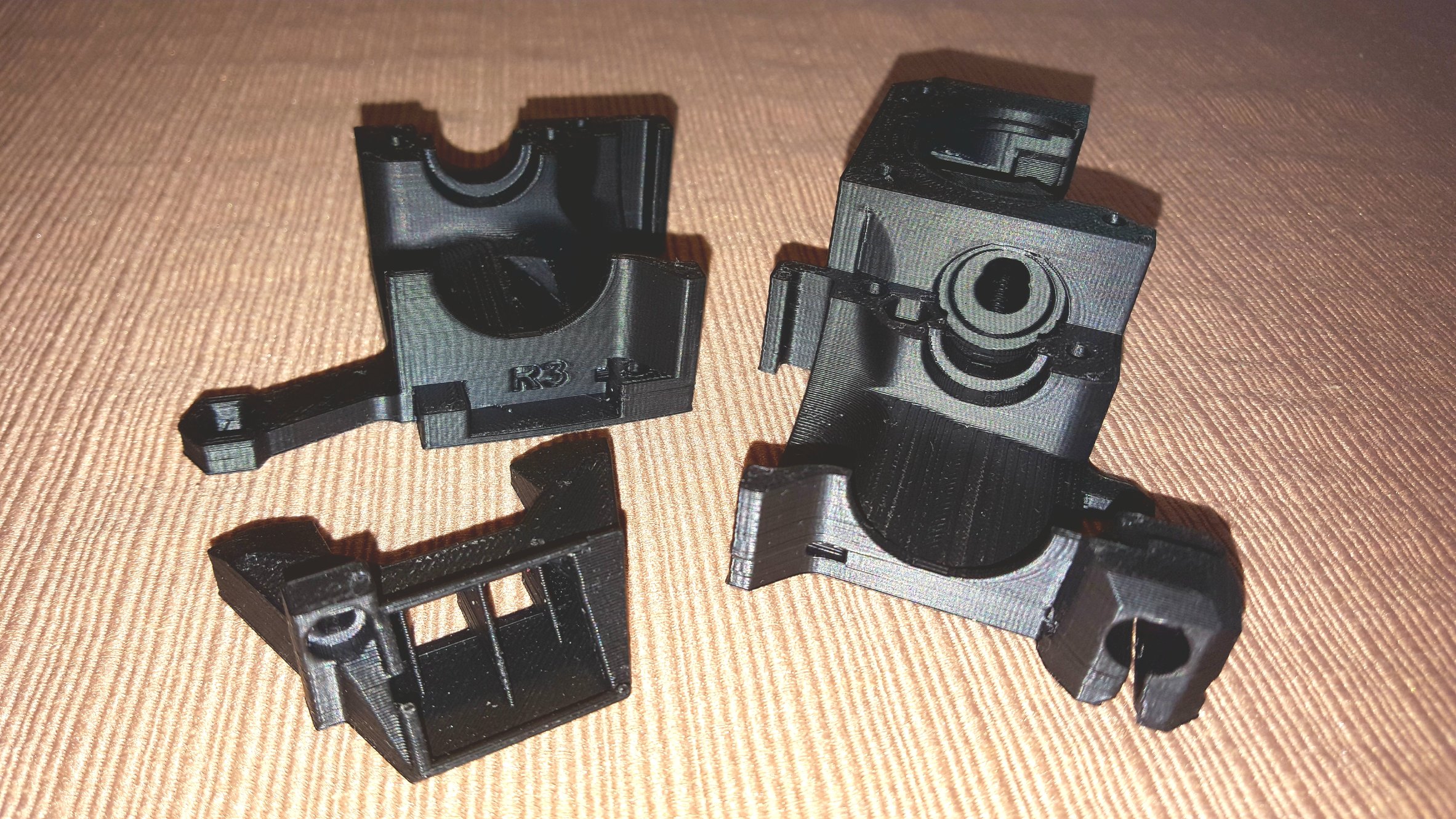

My first ABS - R3 Extruder upgrade

Today I printed my first ABS. I printed several test ducts Using Matterhackers ABS and generic ABS from Slic3r at several temperatures. (Matterhackers says 230 +/- 10) The best result were at 220, however there was still excessive sag in the horizontal bridges. So I activated fan cooling at 30% while printing bridges, and upped print temp to 225 and got a nice duct.

Using this config I printed the front and back Extruder parts

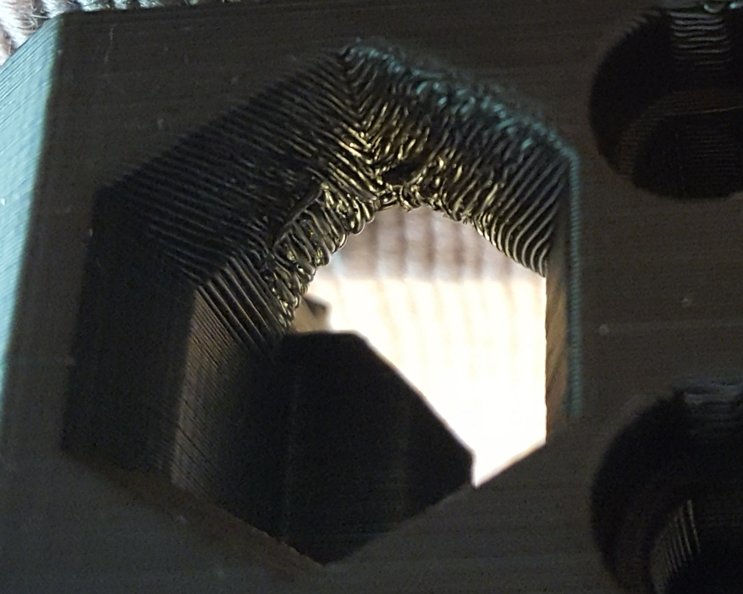

Overall they are nice except for a couple bridged areas:

Any advice as to how to improve these prints much appreciated.

Edited to reduce size of photos

Re: My first ABS - R3 Extruder upgrade

You are on are on the correct lines. Just try adjusting the fan for bridging by 5%. Also it is only the nozzle that needs to be ABS or an other high temperature filament. PETG is the recommended filament for everything else.

Regards,

Martin

Martin Wolfe

Re: My first ABS - R3 Extruder upgrade

You are on are on the correct lines. Just try adjusting the fan for bridging by 5%. Also it is only the nozzle that needs to be ABS or an other high temperature filament. PETG is the recommended filament for everything else.

Martin, thank you for the guidance!

I realize that PETG can be used for the other parts, but I don't have any black PETG, and I thought this would be a good exercise in dialing in and troubleshooting ABS. I'll probably order some black PETG if I'm not happy with my end results after an iteration or two.

Re: My first ABS - R3 Extruder upgrade

Did you get anywhere with printing this? The fan shroud is my 1st ABS print as well.

Edit: I ended up with good results after tightening the idler gears by 1/2 a turn, using a bed temperature of 110, and an extruder temperature of 225, with a bridge fan speed of 30%. I used the 0.20 stock profile.