MK3S+ Extruder clicking and underextrusion for no apparent reason

I have had this printer for just under one year now, and I have had almost zero problems with it until a few weeks ago. All of a sudden it began under extruding, and suddenly stopped extruding altogether. After multiple failed disassembles, cleanings, and cold pulls, I decided to fully take apart the entire hot/cold end and do a deep clean. I made sure to put everything back just as it had come originally when I got the printer. I then reverted back to a file which I knew was flawless (it came with the printer as a sample gcode): The Prusa Tree Frog. It printed sot super well with a few artifacts in the arms, So I decided to go back to the print for my brother's birthday: an ancient red dragon miniature. It failed miserably. I examined it and found that it was also caused by under extrusion. What is wrong with the toolhead? there is only so much that can go wrong.

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

This was printed with Jessie PLA at a variable layer height, and has perfect gcode, making it a benchmark print. It was printed directly after the cleaning of the 3D printer.

This was printed with Jessie PLA at a variable layer height, and has perfect gcode, making it a benchmark print. It was printed directly after the cleaning of the 3D printer.

This was printed with Prusament recycled PETG at 0.2 mm and is the first case of inconsistent extrusion, and eventually cut of and stopped extruding completely.

This was printed with Prusament recycled PETG at 0.2 mm and is the first case of inconsistent extrusion, and eventually cut of and stopped extruding completely.

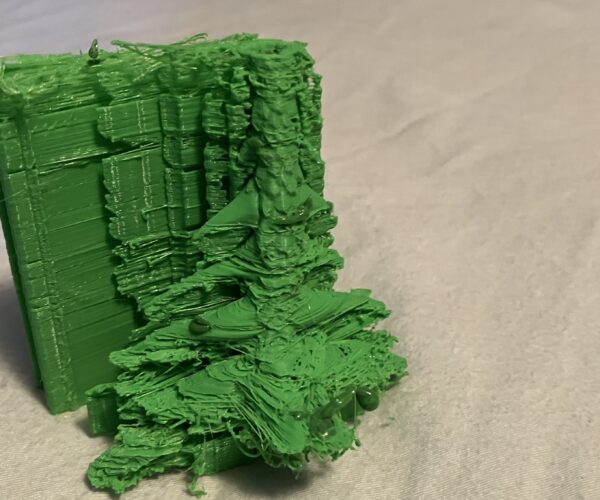

This was printed with Jessie PLA at 0.05 mm as a detail minifigure part (it is the tail of a red dragon) and was printed directly after the Prusa treefrog.

This was printed with Jessie PLA at 0.05 mm as a detail minifigure part (it is the tail of a red dragon) and was printed directly after the Prusa treefrog.

So: Some code prints well and some code fails...

First let's eliminate the file.

Please show us a failed print and the project file:

Save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

Did you replace the nozzle when you rebuilt the hotend? If not, give that a try.

I recently installed a new E3D 0.4mm nickel plated copper nozzle on my MK3S+ printer after a year printing with the original brass nozzle and print quality improved immediately.

Cheers

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

Even though perhaps less likely than a hotend issue, I'd also examine the whole filament path, all the way back to the spool, to make sure there's nothing physically binding the filament.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

What size nozzle are you using? Your last picture; they've finally shown up, is the opposite of underextrusion...

If you still have the standard 0.4mm nozzle then 0.05mm layers are usually a mistake, you are trying to smear out layers at an eighth of the diameter of the aparture causing considerable back-pressure. Try the same model at 0.2mm or 0.15mm layer height, you will see negligable extra detail at low layer heights unless you use a finer nozzle.

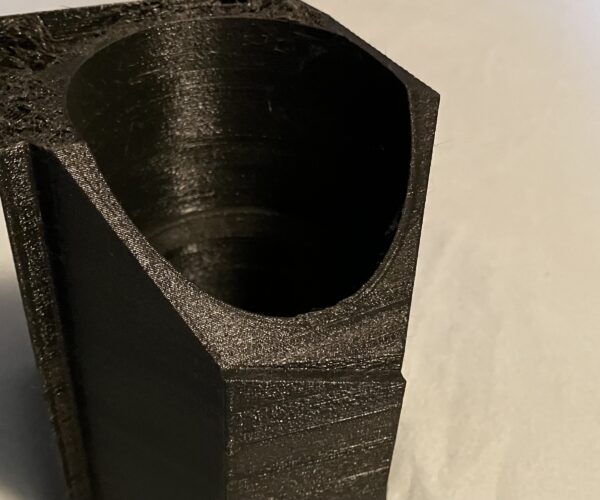

Your second picture, the black part, is the one of most interest. Please supply that as a .3mf as above.

Pictures of your nozzle/hotend assembly from at least two angles might also help us.

Cheerio,

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

I missed the mentioning of 0.05 layer height. I agree with diem, with a standard 0.4 nozzle, anything less than 0.1 is at best pointless or worse, could cause issues.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

Hi all, thank you for responding.

@Diem, here are the files and pictures:

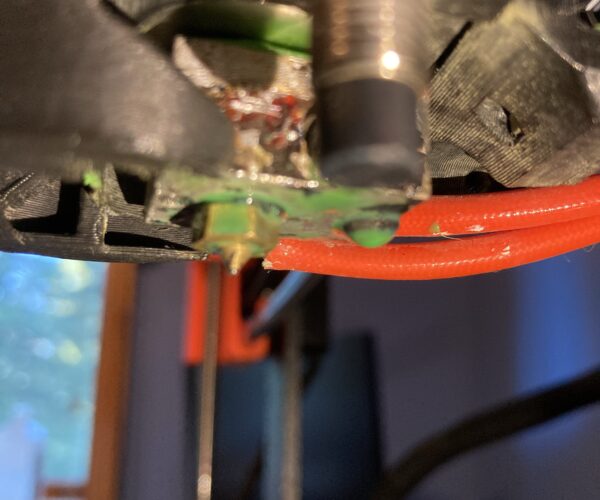

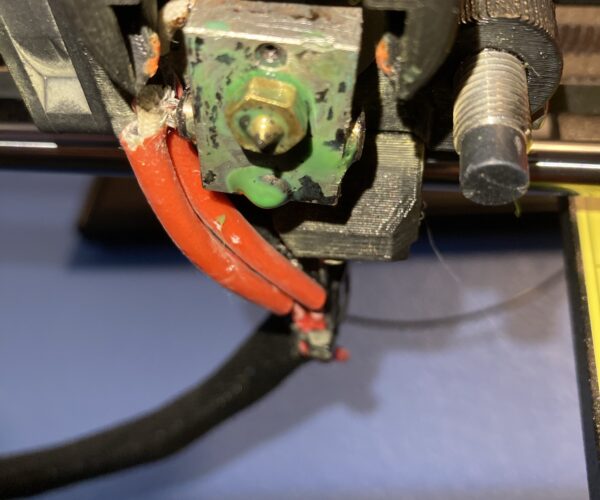

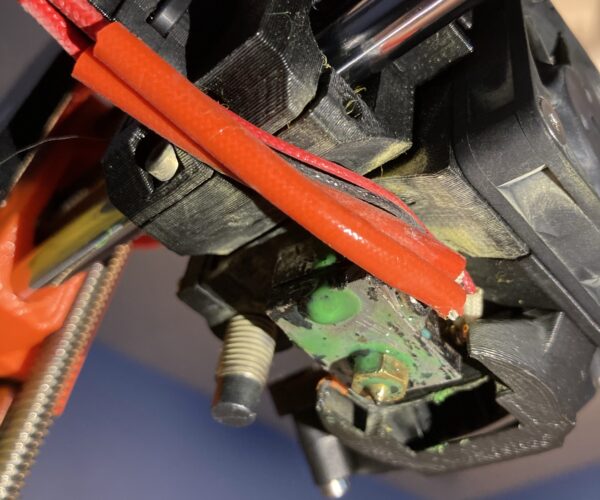

The green glob on the heating block was residual plastic from a failed print where a plastic blob melted all over the whole heating block. It does not affect prints.

[{JT-12_Right}] This was the black part, the "one of most interest."

[{elderreddragon-tailpart2}] This was the green dragon tail which you said was ruined by the opposite of under extrusion.

[{treefrog_variable}] This is the green treefrog, parts of which were printed at 0.05 mm. Actually, The area that was printed at 0.05 mm had a small blob and scar out of the picture, which was similar to what happened to the dragon tail.

As a note, I am using the stock nozzle, but I have printed many things at 0.05 mm layer height, with no problems or under extrusion whatsoever. The other parts of the dragon minifigure were all 0.05 mm and were printed perfectly. I have never noticed the 0.05 mm layer height causing problems before, so do you mind sharing where you learned about that? Thanks for helping out.

@RandyM9, Thank you for the tip! I will look into getting a new nozzle, as the current one has hundreds or maybe thousands of hours of print time on it. What quality improvements did you see with the nozzle you got? If I can fix the problem without replacing the nozzle, that would be nice, but I will still likely get a new nozzle.

@fuchsr, I did check the filaments I used when the print problems occurred. It was feeding into the toolhead well at all times, and none of the filament has much moisture, so thanks for eliminating that.

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

The pictures of the hotend&nozzle are not clear enough to be certain but it looks like filament has been running down from the top of the heatblock; I see you plan to change nozzles, pay particular attention to the diagrams at the bottom of this page:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

The black model turns out to be of less interest now I see the design, I might have sliced with more perimeters but if it fulfils its function that's fine.

The dragon tail prints much faster if laid flat and uses less support; at 0.2mm layer height it's a 3 hour and a bit print. With the back pressure you were building at 0.05mm excess pressure was squirting filament out every time the nozzle reached a less constrained position.

I have never noticed the 0.05 mm layer height causing problems before, so do you mind sharing where you learned about that?

Experience and a few test prints. I rarely go lower than 0.2mm with a 0.4m nozzle. Even with a 0.25mm nozzle I tend to stay at 0.1mm layers.

The smaller the layer the more likely you are to have extruder problems.

Cheerio,

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

@Diem,

Thank you! I appreciate the extensive information and the recommendation on the settings for the dragon tail. It seems that getting a few new nozzles and not going too low with the layer height should fix the problem. I will do that.

Thanks again, @fuchsr, @RandyM9, and @Diem. Your help is very much cherished.

RE: MK3S+ Extruder clicking and underextrusion for no apparent reason

@RandyM9, Thank you for the tip! I will look into getting a new nozzle, as the current one has hundreds or maybe thousands of hours of print time on it. What quality improvements did you see with the nozzle you got? If I can fix the problem without replacing the nozzle, that would be nice, but I will still likely get a new nozzle.

@the3denthusiast - I’m not sure if my original nozzle was beginning to wear or if it had old, burned, residual filament bits stuck inside it, or exactly what the problem was.

My prints began to suffer in quality because too often some filament would stick to the nozzle, then push the newly extruded filament out of the intended path. This eventually caused obvious flaws in the finished print or forced me to abort the print, clean the nozzle, and start over.

The finish of the nozzle had become very dull over the year plus I’ve been printing with it, and no amount of cleaning with a brass or nylon brush restored the original luster like a new brass nozzle.

I wasn’t sure if installing a new nozzle would help, but I knew it couldn’t hurt. A new E3D brass nozzle is maybe $7 US and the nickel plated copper nozzle is maybe double that, so not dreadfully expensive either way. I chose the nickel plated nozzle in hopes that the shiny hard plate will be more durable than plain brass over time and, perhaps, less ‘sticky’ with PETG, which is the material I print most.

The new nozzle immediately restored my printer to ‘like new’ print quality so I’m pleased with the modest investment of time and money for the swap. Of course, your mileage may vary.

OBTW, I’m careful now to only clean the nozzle with a nylon brush as I don’t want to scratch or dull the nickel plating and, I want to avoid the possibility of shorting a heater or thermistor wire which can have expensive consequences.

Cheers