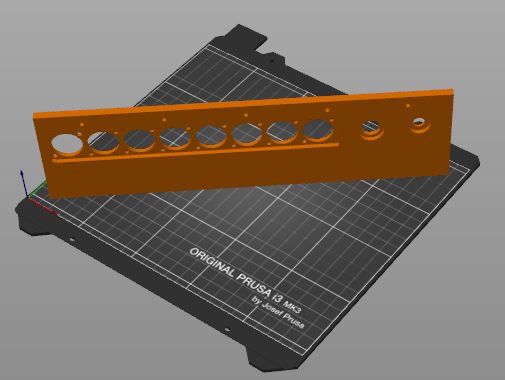

Long Rectangular Panel

Hi All,

Total newbie here. Waiting for arrival of recently ordered MK3S+ (assembled).

I'm going to print enclosure panels for an electronic project prototype starting with the rear panel, which is 11.54"W x 3.188"H x 0.5"T. It has several features in the form of 0.75"DIA holes, smaller holes, countersinks, etc.

To fit it on the MK3S+ bed, I'll have to put the 0.5"T flat side against the bed and put it at an angle.

I'd like to hear your advice on what material to use, infill techniques, and support material (or any other ideas that will make it print better). I've never used a 3D printer before, so please be gentle.

Thanks in advance for you input!

robin

Best Answer by Diem:

If you can shorten it or cut it in two and assemble afterwards it should print well lying flat without the need to tweak the settings, it needn't be so thick either.

As you show it - that's a challenging print.

Is this likely to get warm? If not this should be OK in PLA.

Cheerio,

RE: Long Rectangular Panel

Well, you didn't pick the simplest model to start your 3D printing career! With the size of it, the orientation you're showing is probably the only one feasible, but it'll give you a few headaches. Most importantly, the tiny contact surface may make it hard to get good adhesion. This may lead to (best case) warping at the end of the model, or (worst case) the model may come loose, especially as the model goes up in height. A few ideas to mitigate this issue, but large rectangular objects are notoriously prone to it:

* Make sure your steel sheet is squeaky clean. Wash with dish washing soap and plenty of hot water. After drying and between prints, wipe with plenty of 91+% isopropyl alcohol. Don't touch the print surface with bare fingers.

* Make sure live Z is properly calibrated.

* Make sure your nozzle and heater block are clean and don't have filament stuck to them.

* Slow down first layer to 10mm/s.

* Raise first layer temp by 5 degrees or so.

* Use glue stick or Layerneer bed weld.

* If I had control over the model, I might even model some sacrificial supports in, to side-stabilize the model.

The other issue I can see are the holes. If you could print flat, not a problem. But in this orientation, I expect the top of the large holes to sag, to the point that supports may be required. And conversely, the small holes may be too small to print properly.

I'd print it with variable layer height, 15% gyroid infill. If you need supports, the support defaults in PrusaSlicer have dramatically improved in version 2.4. I use Snug supports, with the following adjustments:

0.25mm z distance 3mm pattern spacing 4 interface layers 75% xy distance 0.2mm interface layer spacing 0mm first layer expansion

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Long Rectangular Panel

Thanks for your reply fuchsr. Exactly the kind of input I was looking for. Adding some external, temporary vertical supports sounds pretty easy.

I do have total control over the design, and since it's a prototype, I could reduce the panel size by eliminating a couple of redundant channels. That would make it so the panel can lie flat on the print bed.

Would that afford a significant improvement in final print precision?

If you can shorten it or cut it in two and assemble afterwards it should print well lying flat without the need to tweak the settings, it needn't be so thick either.

As you show it - that's a challenging print.

Is this likely to get warm? If not this should be OK in PLA.

Cheerio,

RE: Long Rectangular Panel

As diem said, this would be a lot easier to print lying flat. And it's so thin I wouldn't expect warping issued.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Long Rectangular Panel

OK, the fog is lifting and I'm starting to see a path forward. What I'm hearing is that it will be easier and generate better results if I lay the part flat to print it.

I like Diem's comment about making it in two smaller parts and assembling them together. I think I'll give that a try, along with creating a de-featured version that will fit as one piece. I may even try it standing on end as originally depicted, with additional temporary supports. I'm new at this and it will all be good experience.

Thanks, fuchsr & Diem for helping me get started.

I'll attempt to post results after printing...