Issues with SUNLU PETG

Hi,

I recently had successful prints with the Prusament PETG on textured sheet.

I have a stock of SUNLU PETG to use and in particular:

- I don't think that these are sticking issues, because at the beginning the printer can create that small holes without issues (only one hole failed when I tried to print at lower temperatures);

- I cleaned the textured sheet with 90% IPA;

- I tried different extruder temperatures (220-240) and bed temperatures (75-85);

- The filament stayed closed and never opened for months, so I opened the filament only this week.

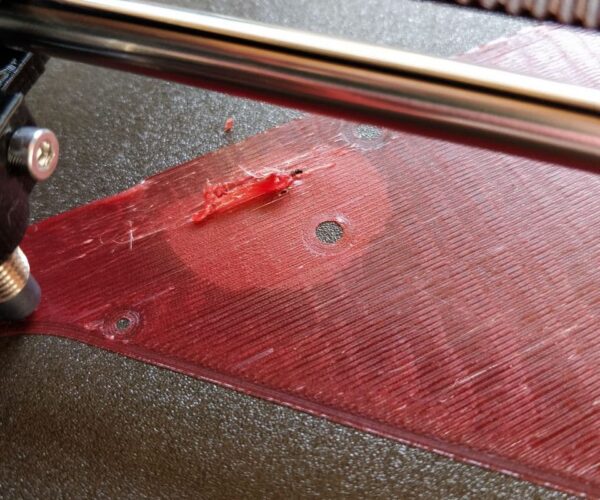

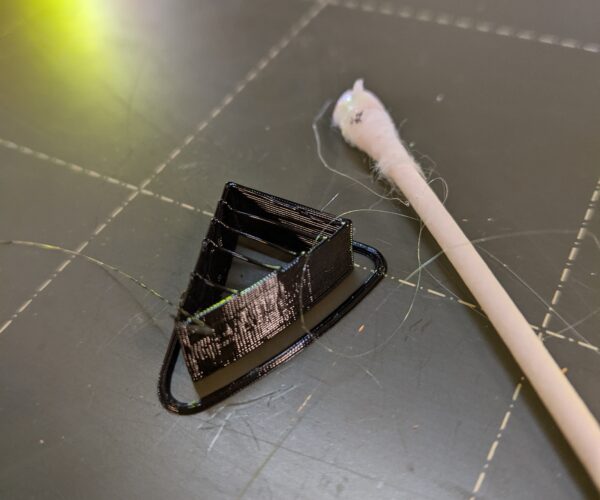

I'm having these print issues that could damage my PINDA sensor by collision:

What can I do?

Thank you for your support,

Andrea

RE: Issues with SUNLU PETG

I don’t like the look of this first layer. I would start with a thorough cleaning of the sheet with dishwasher and hot water, followed by redoing live z. I just finished printing 16 rolls of Sunlu PETG and only had to clean the sheet a couple of times with IPA but had to adjust live z every now and then.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issues with SUNLU PETG

Thank you for your reply 😀

I don't know if it's ok to use water and/or dishwasher as reported here https://blog.prusaprinters.org/how-to-print-on-a-powder-coated-sheet_30178/ (in the video seems that dishwasher shouldn't be used)🤔 .

About the first layer, do you think that nozzle is too high or too low?

I tried to adjust a bit before these prints but that looks strange because with Prusament PETG printed well.

What bed and extruder temperatures do you use for SUNLU PETG? Did you set any other important settings? Are you using the textured sheet?

Thank you

RE: Issues with SUNLU PETG

I know Prusa doesn’t recommend it but a lot of people here use hot water and non-fragrant dish water liquid such as Dawn regularly, with excellent results. And never touch the plate with your fingers.

I use the generic PETG profile with Sunlu filament, didn’t make any changes. I’ve used the Prusa smooth and textured sheet, as well as the BCZAMD textured sheet, the latter being my favorite.

For live z calibration, follow this method:

It has nice pictures to show what good and bad live z looks like

Remember that textured sheets are thinner than smooth so your live z will be more negative.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issues with SUNLU PETG

And why Prusament worked? Who knows. I guess some filaments are more forgiving than others as far as Live Z is concerned. But I’d say most cases of bad adhesion are either sheets not properly cleaned, or incorrect Live Z.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issues with SUNLU PETG

I've tried Esun and unbranded PETGs. I find china brand PETGs really hard to work with and highly hygroscopic to the point that I might need a filament dryer to achieve higher nozzle temp. I can't go higher than 220C without the popping sound and the filament coming out of the extruder looks really rough and uneven. They usually do best when nozzle temp is set 5-15C lower than their recommended temp. So if the sticker attached to the spool says 230-250C try 220C. Or if you're using a particular brand and material for the first time I suggest you print a temp tower like I always do.

Some brands also seem to have varying Live-Z values. Sometimes you need to increase or decrease the Live-Z value for a particular brand. Finding the right Live-Z is critical. You may use the "life adjust Z" calibrations gcodes found in the link above. Or you could create your own similar calibration prints based on your nozzle size, filament and print settings. Simply launch the Prusaslicer, rightclick the buildplate to add shape (box). Set the XYZ values to 75 x 75 x 0.2 mm (just to be clear its 0.2mm not 2mm), choose the system presets or manually input your preferred print settings then slice.

And yeah, prusament PETGs are great. Im still in search of a better PETG that is available locally here in my area. So far I found none. The best ones are overseas (US/Europe) which cost double or triple including tax and shipping.

RE: Issues with SUNLU PETG

Thank you to everyone,

My issue was probably that the noozle was too close to the bed (according to this similar post found here https://www.reddit.com/r/prusa3d/comments/gw59us/first_layer_with_petg_on_textured_sheet_whats/ ).

I solved by changing the live Z from -1.4 to -1.3 and cleaning the bed with IPA 90% (I've putted IPA in two pieces of toilet paper and then I cleaned the cold bed with a bit of pressure).

I successfully did 5-6 long prints with both filaments withouth adhesion issues.

For SUNLU PETG I used default "Generic PETG" profile and for Prusament PETG I used its profile.

The only issue I found is that randomly there are very small parts of SUNLU filament that are burned (the color was red and became black in that point). Maybe too high temperature or some filament stayed attached to the nozzle too much...

I hope that I gave some useful information to someone 😉 😀

RE: Issues with SUNLU PETG

Glad it works now. PETG likes to curl up on the nozzle and can get burned. Make sure you clean the nozzle and the heat block thoroughly.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issues with SUNLU PETG

@fuchsr

This is especially true if you Z is too low.

--------------------

Chuck H

3D Printer Review Blog

RE: Issues with SUNLU PETG

I got sent a coupon and got a roll of Sunlu/Jayo petg for $10 off. It came yesterday so I printed some small lure parts first, and then moved up to a couple of lures. I had no challenges with this material - it printed like it was prusament. I put it on my "default" z value for petG on smooth sheet and pressed go. The prints were good, the first layer was good.