Issue: print head prints in the air after a few hours of successful printing

Hi all!

I am having an issue with my MK3S (Grey Prusa PLA, .25 nozzle, standard temps, Cura slicer configured for Prusa MK3S), although it had been working quite neatly for a few months.

When printing this object (the big flat portion on the bottom), I have a weird issue (for which I found nothing on this forum or on Google): the nozzle starts printing in the air. I have tried this piece 3 times, including once at a bigger size (with more slots, see the picture), and every time it seemed to happen roughly at the same time. I come back and find a blob of plastic on the nozzle, and the print head moving as it should but above the print.

Before the last failed try, I tried a similar design, but in smaller (with only one slot), and it worked perfectly.

Any idea/tip would be greatly appreciated.

As you can see from the picture, I have another issue, albeit less important: there are filaments in the "holes", that should be on the outline, but I gess didn't stick. If you know how to tackle this issue, I'd love to hear your solution as well.

Best Answer by --:

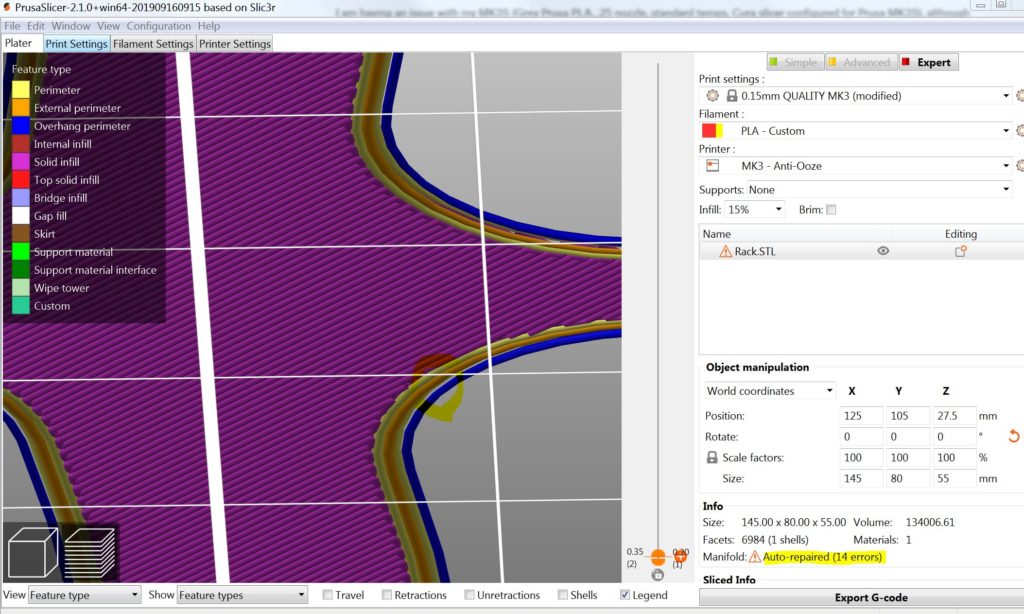

The radiused bevels in the top surface will be impossible to print without supports. The curves exceed the printers ability to form layers ... that's where your problems start. Those holes should be chamfered for printing. The image shows the perimeter trying to print in free space. That's why you get stragglers in the first few layers.

The part also has errors. Hard to say what they are, but they may impact printing.

And last: if you unload filament after it stops printing, what does the tip look like?

RE: Issue: print head prints in the air after a few hours of successful printing

The radiused bevels in the top surface will be impossible to print without supports. The curves exceed the printers ability to form layers ... that's where your problems start. Those holes should be chamfered for printing. The image shows the perimeter trying to print in free space. That's why you get stragglers in the first few layers.

The part also has errors. Hard to say what they are, but they may impact printing.

And last: if you unload filament after it stops printing, what does the tip look like?

RE: Issue: print head prints in the air after a few hours of successful printing

Thanks a lot for your help, Tim.

The curves exceed the printers ability to form layers ... that's where your problems start. Those holes should be chamfered for printing.

That makes sense, I put a chamfer, it will be better now.

The part also has errors. Hard to say what they are, but they may impact printing.

That's weird, its quite a simple part, idk what caused them. I tried to change a few things on SolidWorks, but the errors were still here. So I repaired the stl online, no more errors. Here it is, in case that helps.

And last: if you unload filament after it stops printing, what does the tip look like?

Good question, turns out I noticed it was unusually damaged: it was flattened and brittle around 8cm from the tip, which I don't remember happened before.

Thank you very much and have a good day!

RE: Issue: print head prints in the air after a few hours of successful printing

As far as I can tell the new repaired file should print without any issues. An option to chamfers is to start the radius so that the initial angle is 60 to 70 degrees, that way you aren't trying to print challenging 87 degree overhangs. That will allow a more attractive part and still be printable.

The filament sounds like it was chewed by the extruder gears. Normal with jams. The very tip is of interest though: especially any stubs that formed.

RE: Issue: print head prints in the air after a few hours of successful printing

There was indeed a small portion wider just at the tip, that looked like the photo you posted here, a bit shorter in length. Unfortunately, I threw it so I can't measure anything, I just lanched a print of the repaired file, and will keep you posted. There also was a little string that came with the filament when I unloaded it.

Additionnaly, I don't get jams, but sometimes clicking in the extruder, if it helps. (I tried to clean then grease the gears, cut a bit the PTFE tube that was overshooting a bit, it still clicks at times).

Thanks a lot!

RE: Issue: print head prints in the air after a few hours of successful printing

There was indeed a small portion wider just at the tip, that looked like the photo you posted here, a bit shorter in length. Unfortunately, I threw it so I can't measure anything, I just lanched a print of the repaired file, and will keep you posted. There also was a little string that came with the filament when I unloaded it.

Additionnaly, I don't get jams, but sometimes clicking in the extruder, if it helps. (I tried to clean then grease the gears, cut a bit the PTFE tube that was overshooting a bit, it still clicks at times).

Thanks a lot!

A clicking noise is never a good sign and made lead to underextrusion soon or later. I would try to eliminate it by either reducing the print speed or watching your ambient temperature. I may have different causes, but I would investigate because it can cause serious problems further down the road.

3D Druck für Einsteiger leicht gemacht: www.3d-druck-lernen.de

RE: Issue: print head prints in the air after a few hours of successful printing

Thanks, will definitly do!

RE: Issue: print head prints in the air after a few hours of successful printing

Small update : the print indeed went perfectly, after putting chamfers and repairing the .stl file