Increased extrusion width for external perimeters in Vase Mode does not work as expected

Hi all

I am experimenting with Vase Mode and increased extrusion width to see if I manage to print waterproof stuff. For this reason I installed a 0.6mm nozzle on my original MK3S+.

To start I tried to print the model of this cool low poly bunny: https://www.prusaprinters.org/prints/36067-bunny-vase-mode

My goal was to print it in Vase Mode with 0.3mm layer height and 1.0mm extrusion width for external perimeters. When looking at the sliced model in PrusaSlicer, there were no visible gaps with these settings. So I expected to see no gaps between layers when printing it.

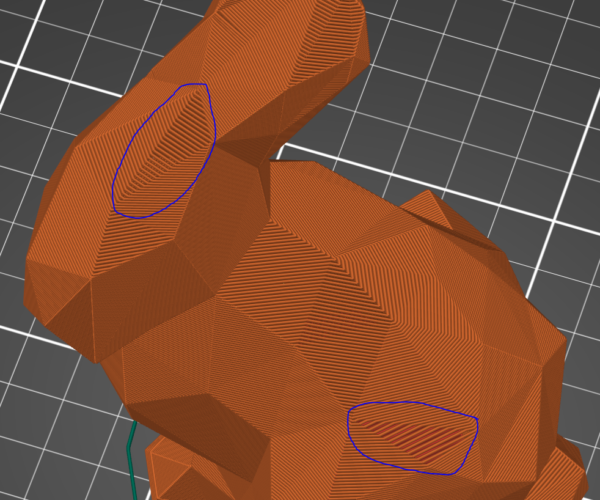

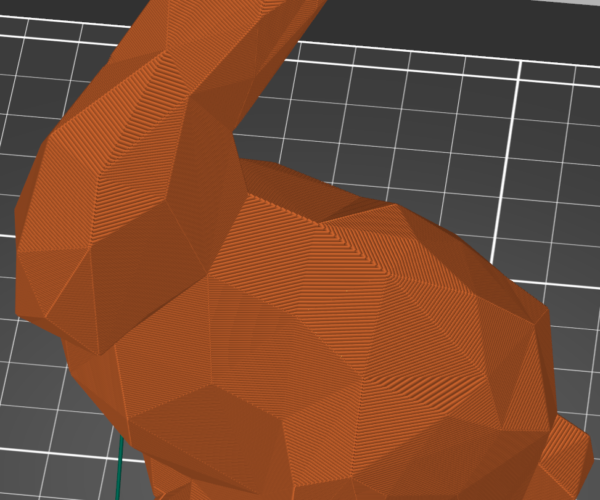

Here a couple of pictures to explain what I'm trying to do:

Model Sliced with default settings for 0.6mm nozzle. (0.65mm extrusion width). Clearly, there are visible gaps:

Model sliced with 1.0mm extrusion width for external perimeters:

no gaps visible (no red bottom layer shining through).

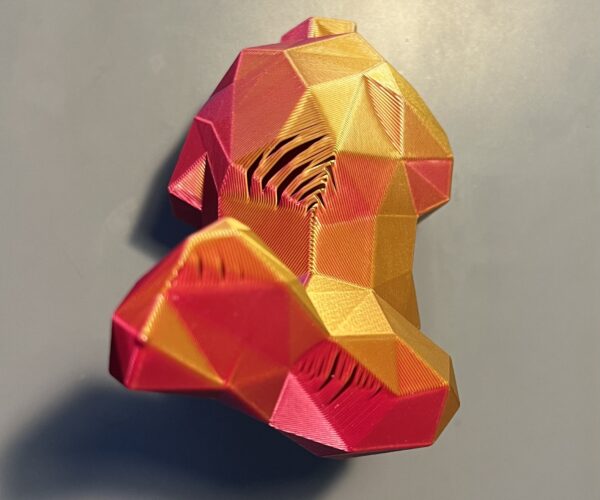

Final result:

I have no picture of it but the first few solid layers had a wide 1.0mm external perimeter and as soon as the spiraling started the layer width was reduced. As you can see on the picture, the layers are nowhere near the 1.0mm width I expected.

My printer is sitting in an IKEA Lack Enclosure and has no mechanical modifications apart from the 0.6mm nozzle. I am quite happy with the prints I did so far and think the printer is ok. I am using PrusaSlicer Version 2.3.3+win64.

Anybody has an idea what happened and any ideas how I can I achieve what I want to do?

best regards

Best Answer by JoanTabb:

You will probably find this works better with lower layer heights,

the larger the layer height, the greater the offset between layers on slopes, the greater the likelihood of failure.

you can probably get away with wider extrusion width.

regards Joan

RE: Increased extrusion width for external perimeters in Vase Mode does not work as expected

You will probably find this works better with lower layer heights,

the larger the layer height, the greater the offset between layers on slopes, the greater the likelihood of failure.

you can probably get away with wider extrusion width.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Increased extrusion width for external perimeters in Vase Mode does not work as expected

To add to what Joan said, you can probably get away with an extrusion width that is %200 of your nozzle, which would put it at 1.2.

Mk3S+,SL1S

RE: Increased extrusion width for external perimeters in Vase Mode does not work as expected

Thank you both for the suggestions. I tried to print it now with 1.2mm extrusion width. I scaled the bunny to 75% (compared to previous 150%) to save some time and material. Worked pretty well this time 👍

I love the look of this magicPLA "Sunset Sky" 😀

With the small print I had to reduce the print speed to like 40% when it started to spiral print the bunny's ears. The material had not enough time to solidify otherwise because one circle was so short. The ears are a little dented because of this 😆

When I start to print the next model I think I'll also try to reduce the layer height.

Thanks again! It helped a lot!

RE: Increased extrusion width for external perimeters in Vase Mode does not work as expected

as soon as the spiraling started the layer width was reduced

If this is really true, you should be able to see this in the slicer preview in the view "Width"...

RE:

Hey Stefan,

I think the Slicer works well. I read a little bit about flow math and think what I observed was related to this:

Quote https://manual.slic3r.org/advanced/flow-math :

However note that extrusion width can be controlled only when extruding over an existing surface (such as a previous layer or print bed). If we extrude in free air (i.e. when bridging), the resulting shape will be always round and equal to the nozzle diameter:

I guess because the layer offset when printing in vase mode with 0.3mm layer height can get quite big, it is very similar to extrude into free air. Since there is no solid layer underneath onto which the material can be pressed, the extrusion width corresponds to the nozzle diameter.