How do I print this speaker port?

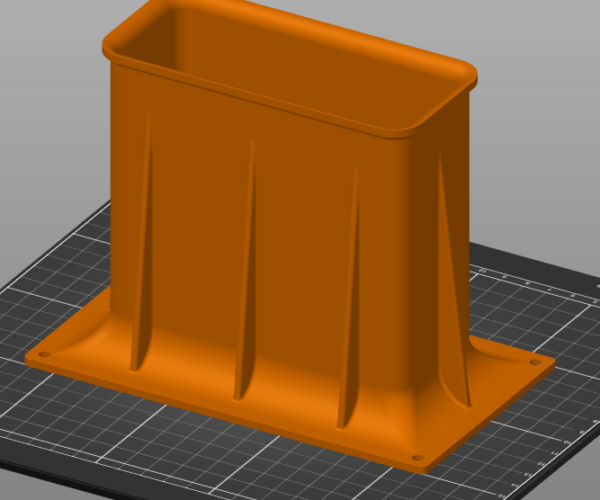

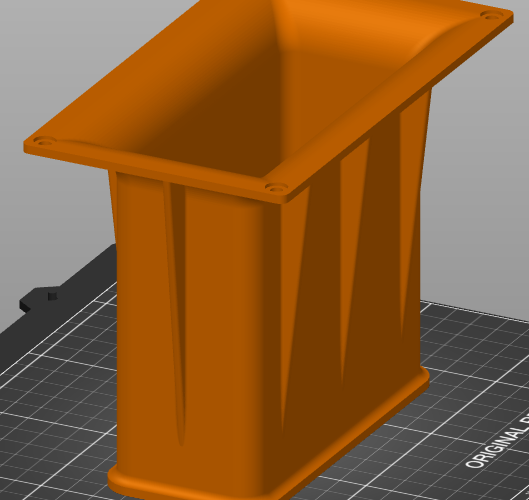

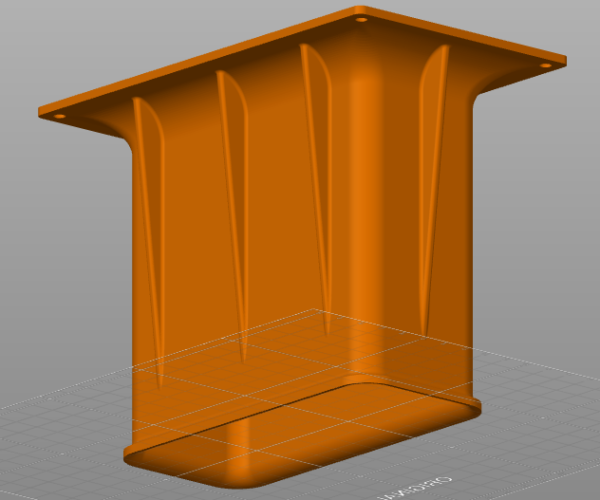

I need help with this speaker port design. I've tried printing it with the flare side down, using variable thickness slicing and the 0.6 nozzle. It seems that there are still some perimeters but when I print with supports, it looks like crap. I'd like to not have to use supports, but I don't know if it's possible. If I print it with flare side up, then adding supports doubles the print time. Maybe that's my only option? Thank you!

RE: How do I print this speaker port?

Print like in first picture.

Can you change the model?

The upper flange should have 45 degrees hook to the model, then you can print without support.

RE: How do I print this speaker port?

its not going to print very well if you do it like the first picture, the angles on the inner cone will look hideous your best bet is to print it the way you had in the second and third images and use supports. that will keep the inside (visible parts) as clean as possible and you can remove the supports with the ugly stuff hidden behind, without altering the design.

The Filament Whisperer

RE: How do I print this speaker port?

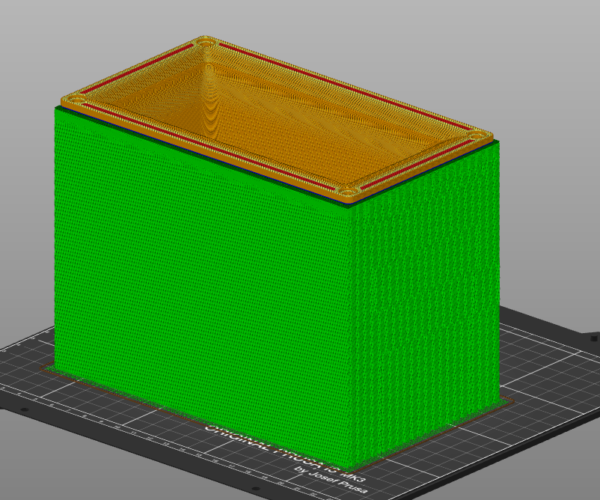

I looked at your .3mf I think you should make an attempt if printing this at .03 layer heights to use the layer editing and refine the top of the cone, the top being referenced as you have it in the .3mf (which by the way, I think is the correct printing orientation) also as this is to be a sound related item I would print it solid, either by adding perimeters or printing with solid infill ( personally I would go with adding perimeters).

Good Luck

sorry, as you may know you have about 30 seconds to edit a post around here before you can't touch it again.

The Filament Whisperer

RE: How do I print this speaker port?

Yeah, it seems that there's no real easy way to print this without supports. The flange side down won't work. Printing flange side up, in one piece, results in about a 17 hour print with the 0.6 nozzle. My other option is to split the part in two, and use someone like heat inserts to bring it back together.

RE: How do I print this speaker port?

whats wrong with taking 17 hours? as long as your getting the part you want the way you need it. if your looking to print many of them then take the time to model custom supports, and tune the print, that will decrease the print time and improve the quality as well as use less material.

The Filament Whisperer

RE: How do I print this speaker port?

whats wrong with taking 17 hours? as long as your getting the part you want the way you need it. if your looking to print many of them then take the time to model custom supports, and tune the print, that will decrease the print time and improve the quality as well as use less material.

I guess I was trying to keep the print time down because my friend needs 6 of them in total. But I'm definitely open to modifications. Do you think the best thing to do would be to change the flare angle to 45 degrees, and then I wouldn't need supports? Or design some custom supports? I'm not sure how to do that...are custom supports better than the ones that are drawn by PrusaSlicer?

RE: How do I print this speaker port?

Well, here's how I would look at it.

when your talking about sound, the shape of a thing can be very impotent to sound quality. so you and/or your friend should decide how, or if changing the shape in a way that will decrease print time will effect sound quality.

IF you determine that it can be done to your satisfaction, then "I say" go for the change in shape that will negate the need for support. IF you decide it can't be done, then (supports and time) are your only option.

IF your good at modeling then you probably won't have an issue with modeling custom supports and that would be the way to go for (time and material) savings.

IF your modeling skills are not high (no shame if they aren't) and /or your not wanting to change the shape then I would stick with the Prusa generated supports, then just start printing. (and tell your friend it's going to take 8 days in-case you have a failure).

As to the question "are custom supports better than the ones that are drawn by PrusaSlicer?" the short answer, YES !, yes they are, with the caveat being, I have a high skill set for such things. in many ways it all comes down to personal choice and the needs of the project, weighed against the available skill set.

The Filament Whisperer