Help - Prusa MK3S with 0.6mm CHT Nozzle - Artifacts in the sidewalls

Hello Everyone,

i just changed my nozzel from a 0.4 E3D Nozzel to an CHT with 0.6mm.

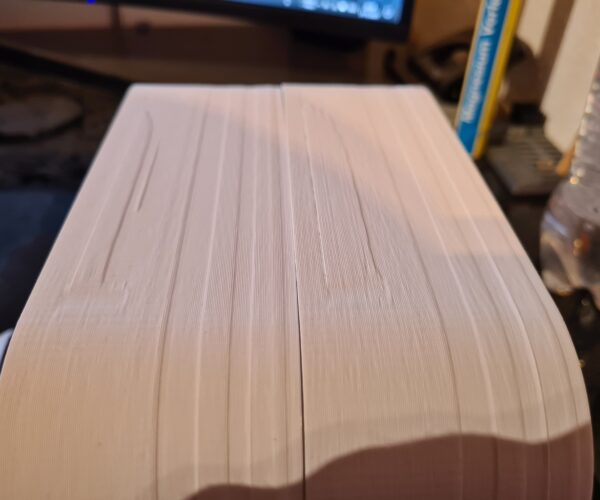

When printing my model with it, the walls have strange artifacts (attached pictures), even if i turn the speed way down....

Any idea what causes them?

With the 0.4mm Nozzel the prints are very clean and dont have these problems...

Best Answer by bobstro:

I believe you are referring to those variations in what would be vertical surfaces as they print. Do you get the same variations when printing a perfectly vertical surface like a cube? There is a common phenomenon that you'll encounter as vertical surfaces vary ever so slightly during a print. This was given the unfortunate name of "buldge" in earlier posts. Deviations in wall thickness can occur as layers transition:

- Between solid infill and sparse infill.

- Between sparse infill and gap fill

- When the number of perimeters increases or decreases between layers.

Happily, the "buldge" misspelling in that earlier post has made the problem very easy to search for. It's not truly a bulge but can give that appearance in some circumstances. There are several threads you might want to look through:

Unfortunately, no single fix has been identified that will work in all cases, but a few things that help:

- Be sure you're not just seeing the effect of minor warping/lifting/curling along edges or in corners. This can really throw troubleshooting off. Rotate the print and verify the problem occurs in the same place.

- Slow down external perimeter speeds (and all speeds in general). If the nozzle is moving a bit too fast, you get slight under extrusion on some layers. These are apparent as adjacent layers print with slightly different extrusion rates. I use 25mm/s for external perimeters when appearance is important.

- Calibrate your extrusion multiplier for each filament. Any slight over or under extrusion can produce very small but noticeable variations in layers with different features (e.g. infill, gap fill, top solid infill). The closer your slicer settings match your actual printer and filament, the more accurate the gcode will be.

- Calibrate linear advance (LA) for each filament. LA adjusts the flow of filament to compensate for acceleration and deceleration. If it's not right, you may see artifacts even away from features such as bumps or hole on the same layer. In some cases, a hole on one wall causes imperfections on the far side of the print.

- Add an external perimeter if vertical walls allow it. The thicker combined perimeter allows the filament flow to even out.

- Tweak perimeter extrusion widths. The problem can appear when the slicer switches between gap fill, sparse infill, and solid or top infill. If you can find a multiple of perimeter widths that minimizes these transitions, it can work for a specific print.

- If you are the part designer, make vertical free-standing walls thicker. IME, at 1.5mm thick, the problem is less noticeable. You can try for a multiple of extrusion widths, although be aware the PrusaSlicer does some internal calculations for overlap between extrusions that can throw you off.

- Check cooling. Variations in fan speeds can cause changes in print appearance.

Unfortunately, with the current state of FFF consumer-grade 3D printing, we still have to do some hand-tuning for specific prints. I've gotten to the point that I can usually eliminate the effect to my satisfaction. Dig through those threads for examples. Contrary to some theories, this is not exclusively a PrusaSlicer thing.

In your specific example, slice the part and spend some time in preview mode checking to see if the defect aligns with any shifts in infill, solid layers, transition from perimeters to sparse infill or gap fill, etc. If you'd save your part & settings off in a 3MF project file, zip it up, and attach it to a reply here, we may have better suggestions.

Be aware that although your new nozzle is capable of much higher throughput rates (aka maximum volumetric speeds), filament still have maximum rates at which they can be processed.

The Prusa Benchy hull line notes might also be interesting.

RE:

I believe you are referring to those variations in what would be vertical surfaces as they print. Do you get the same variations when printing a perfectly vertical surface like a cube? There is a common phenomenon that you'll encounter as vertical surfaces vary ever so slightly during a print. This was given the unfortunate name of "buldge" in earlier posts. Deviations in wall thickness can occur as layers transition:

- Between solid infill and sparse infill.

- Between sparse infill and gap fill

- When the number of perimeters increases or decreases between layers.

Happily, the "buldge" misspelling in that earlier post has made the problem very easy to search for. It's not truly a bulge but can give that appearance in some circumstances. There are several threads you might want to look through:

Unfortunately, no single fix has been identified that will work in all cases, but a few things that help:

- Be sure you're not just seeing the effect of minor warping/lifting/curling along edges or in corners. This can really throw troubleshooting off. Rotate the print and verify the problem occurs in the same place.

- Slow down external perimeter speeds (and all speeds in general). If the nozzle is moving a bit too fast, you get slight under extrusion on some layers. These are apparent as adjacent layers print with slightly different extrusion rates. I use 25mm/s for external perimeters when appearance is important.

- Calibrate your extrusion multiplier for each filament. Any slight over or under extrusion can produce very small but noticeable variations in layers with different features (e.g. infill, gap fill, top solid infill). The closer your slicer settings match your actual printer and filament, the more accurate the gcode will be.

- Calibrate linear advance (LA) for each filament. LA adjusts the flow of filament to compensate for acceleration and deceleration. If it's not right, you may see artifacts even away from features such as bumps or hole on the same layer. In some cases, a hole on one wall causes imperfections on the far side of the print.

- Add an external perimeter if vertical walls allow it. The thicker combined perimeter allows the filament flow to even out.

- Tweak perimeter extrusion widths. The problem can appear when the slicer switches between gap fill, sparse infill, and solid or top infill. If you can find a multiple of perimeter widths that minimizes these transitions, it can work for a specific print.

- If you are the part designer, make vertical free-standing walls thicker. IME, at 1.5mm thick, the problem is less noticeable. You can try for a multiple of extrusion widths, although be aware the PrusaSlicer does some internal calculations for overlap between extrusions that can throw you off.

- Check cooling. Variations in fan speeds can cause changes in print appearance.

Unfortunately, with the current state of FFF consumer-grade 3D printing, we still have to do some hand-tuning for specific prints. I've gotten to the point that I can usually eliminate the effect to my satisfaction. Dig through those threads for examples. Contrary to some theories, this is not exclusively a PrusaSlicer thing.

In your specific example, slice the part and spend some time in preview mode checking to see if the defect aligns with any shifts in infill, solid layers, transition from perimeters to sparse infill or gap fill, etc. If you'd save your part & settings off in a 3MF project file, zip it up, and attach it to a reply here, we may have better suggestions.

Be aware that although your new nozzle is capable of much higher throughput rates (aka maximum volumetric speeds), filament still have maximum rates at which they can be processed.

The Prusa Benchy hull line notes might also be interesting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE:

First of all THANK YOU for your fast and extensive analysis of my problem.

You where complitity right. Every change in thickness was at a z-hight in which something change (most of the time a cutout started or ended)!

Thanks to you for pinting me in the direction of the "infill types" i was able to solve the problem.

The solution for my problem was the option detect thin walls (i hope that is the correct translation, my slicer is in german...

It was not aktivated in my first trys and the walls where build out of 3 perimeters. When i activated it the middle was was changed to "gap-fill"

Now the walls are without the problems!

Thank you again!