Help getting consistent support underside for precision part

Hi, I have an item I make that I use a support for and when I break off the support the underside isn't always consistent sometimes none of the little support bridge parts break off other times half of them do and this fits tightly into another piece so I was wondering if there is a way to get my support settings where I can get a consistent underside when I do break off the support.

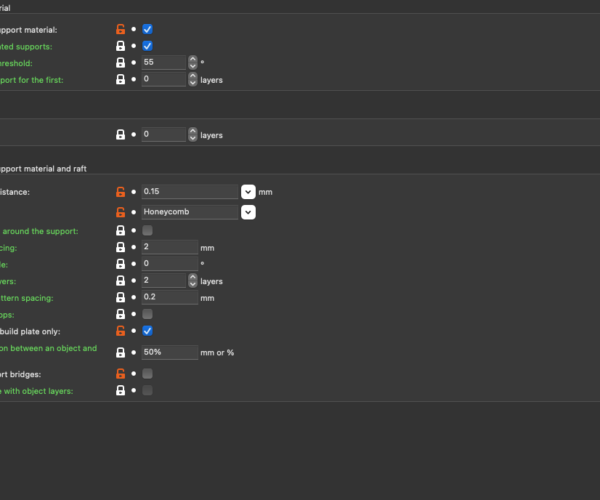

I've attached pictures of the item and my support settings below.

Support settings

I guess it's dogma now that the stock support settings are suboptimal and make the supports hard to remove. Here's a different set of parameters that are frequently cited and have worked well for me:

0.25mm z distance

3mm pattern spacing

4 interface layers

75% xy distance

0.2mm interface layer spacing

Now, while these settings work a lot better than the stock settings, you're never going to get a squeaky clean, great surface. That's just the nature of the beast.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/