Flexible filament printing issues after upgrade to MK3S+

Hey,

I just updated MK3S to MK3S+ and I am having issues with printing flexible filament. On MK3S I had issues with filament clogging at the top around bondtech gears, but releasing bondtech door screw fixed that issue and I had no problems with flexible filament afterwards.

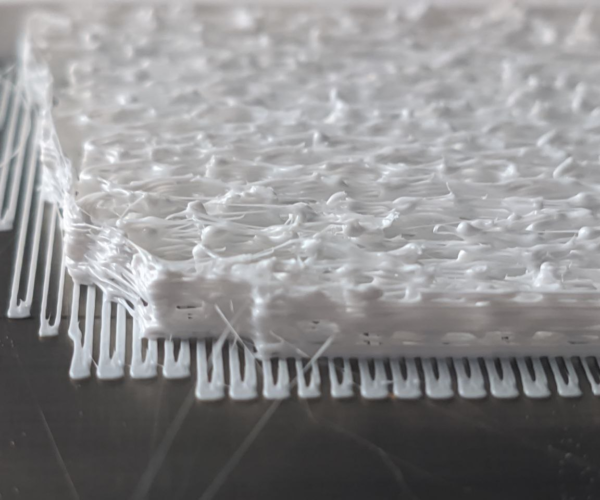

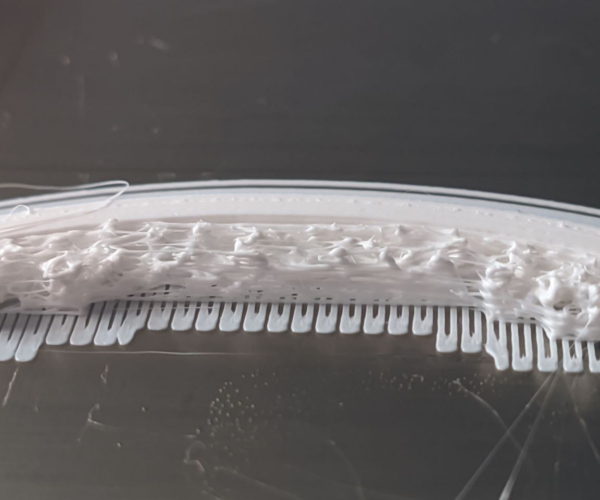

Now I have same issue, flexible filament drives around wheels and pushes to sides. I checked if I have wheels aligned correctly, and yes, they are correct. I checked if nozzle is correctly installed and yes it is. I checked first layer, and I have enough space for flexible filament to go out. I tried printing different filaments, and no issues.

I made it print first layer by removing screw completely and holding gently bondtech door by hand. But this is not best way to print.

If I put screw in it, it overtightens, even on smallest level, and extruder clicks/or filament goes out by side.

Is this common problem or I have something wrong?

I ask for help, from anyone 🙂

Best Answer by ssill2:

Glad you got it working. I've found I typically don't have to mess with the idler bolt any more. I use the same tension for rigid filaments like PETG/PLA that I do with TPU.

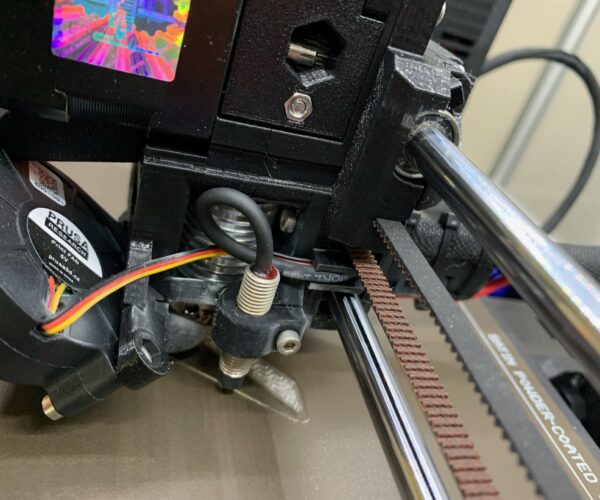

I'm printing with some clear ninjaflex right now. Here's what my idler bolt looks like.

It's just flush with the hex nut. I've not tried any 30d filament, or any filament on the d shore hardness scale so perhaps I would have to loosen it more for that. Glad you got it working though

RE: Flexible filament printing issues after upgrade to MK3S+

it's usually a combination of loosening the idler bolt and reducing speed. It depends on the shore hardness of the material. Temperature. In my experience with having the filament wrap around the gears was idler bolt being too tight and trying to print too fast, like faster than say 20mm/s.

Things you might mention here:

The brand/type of filament you're using. e.g. NinjaFlex

The shore hardness, e.g. 85A, 95A, etc

Also if you could zip up your .3mf and attach here we could see what you're doing.

RE: Flexible filament printing issues after upgrade to MK3S+

Filament used is: https://filberlogy.com/en/fiberlogy-filaments/fiberflex-30d/

I managed to fix the issue by releasing screw even more, and ramming nut on other side with screwdriver hard.

Feels to me like design issue, so screw can't be controlled more precisely, as it used to be on MK3S.

Pushing nut back with screw helped... I hope it stays that way.

great news

Glad you got it working. I've found I typically don't have to mess with the idler bolt any more. I use the same tension for rigid filaments like PETG/PLA that I do with TPU.

I'm printing with some clear ninjaflex right now. Here's what my idler bolt looks like.

It's just flush with the hex nut. I've not tried any 30d filament, or any filament on the d shore hardness scale so perhaps I would have to loosen it more for that. Glad you got it working though

RE: From Hero to Failure

Well, I have again issues with bolt tensions.

There are two states I have:

- Clicking noise of filament going into side

- Filament not moving as it's not tense enough

I did not change anything, but tension got a lot worse...

I am feeling so hopeless so I am thinking about doing same changes as done here: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/how-do-i-stop-tpu-coming-out-the-side-of-the-extruder/paged/2/#post-105916

I thought so maybe issue was with filament, so I dried it, then I swapped for completely new one.

I tried setting tension again and again...

I managed to do 8x prints before it failed...

If anyone has any idea how to solve this tension problem in MK3S+, I will be happy for any advice.

Here are settings I am using for print: https://transfer.sh/1llOWha/Test.3mf

hmmm

30D looks to be equivalent to 80A. The softest filament I've tried printing with is 85A(ninjaflex). If you're underextruding I'd say you're trying to print too much(max volumetric speed), too fast, or not high enough temp. Unfortunately I don't have any of that kind of filament to run a test with. The standard semiflex profile, with temperature adjustment works fine for the ninjaflex though.

-

Problem is so this profile worked in the past....

I think main issue is tension and I will try to buy longer screw (45 mm) rather than original 40 mm.

Larger temp makes filament "boil" uncomfortably while printing, even now I am over by 5 C from manufacturer recommended temps.