First layer issue

Hi,

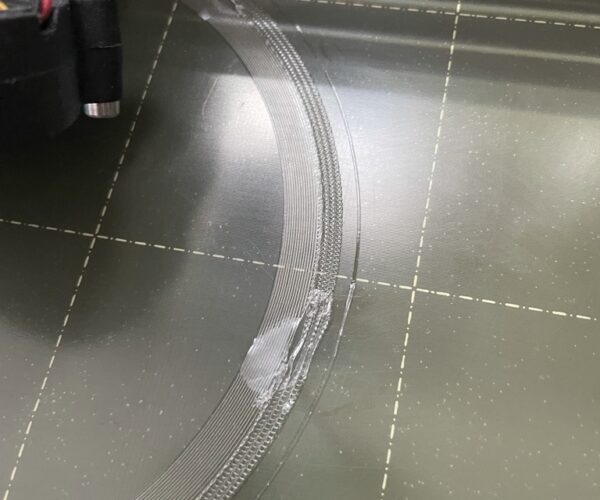

everytime I try to print something with this filament (Sunlu transparent PETG), my first layer has some issues at some points of the bed (not sure it's always at the exact same position though).

What could cause this issue? Bed temp? Extruder temp? First layer calibration?

I'm printing with:

- MKS3 (and stock profile)

- 0.20mm Quality (stock profile)

- Nozzle 210°

- Bed 80° (same issues at 70°)

Thanks for any insight/test I can run.

Chris

RE: First layer issue

Normal printing temps for petg filaments are in the 230-250 degrees range, 210 sounds way to cold.

Also the best way to debug issues and check out your settings is if you save your Prusa Slicer project file (File>Save Project As). That will save a .3mf file. Take that file, zip it into an archive and attach it here. Must be zipped for the forum to accept the file type.

A 3mf contains your model as well as ALL your settings/modifiers/placement etc. It allows us to slice it exactly as you are doing and then go through the previews and check for anything. We can also if needed export the model and check that too.

Also I hope you are using a release agent printing PETG on the smooth sheet ? It can stick so much it damages the sheet trying to remove parts.

RE: First layer issue

@neophyl

The sticker on the filament says PrintTemp 200-220°. I'll try to export/archive ASAP, thanks.

RE: First layer issue

I looked up the temps for clear esun petg on amazon and that said 230-250 which puts it squarely in the normal range for petg. Not surprising as clear is the natural state of petg so it shouldnt have any additives in it.

RE: First layer issue

I'm not using eSun but SUNLU, this one: https://www.amazon.fr/SUNLU-Filament-Diameter-Tolerance-Transparent/dp/B07F649SKK

So you think I should just ignore the sticker on the filament and the recommended temp from amazon description, and just try hotter like other PETG then? No risk involved?

Also, would low temp cause the issue I'm seeing (I though it looked more like too hot 🙂 ).

Beginner here, trying to learn, thanks for your insight!

RE: First layer issue

Here is the attached 3mf file.

RE: First layer issue

That link takes me to a page no longer exists error. I did a search though and found it. https://www.amazon.co.uk/SUNLU-Filament-Dimensional-Accuracy-Transparent/dp/B07THZMPBF/ref=sr_1_5?dchild=1&keywords=sunlu+clear+petg&qid=1620215905&sr=8-5

The one I found above for Sunlu on the amazon store states 235-245c printing temp though which is what I would expect for a petg.

The common thing to do with a new filament is to print a temperature tower. Google that, you will find lots of hits. Basically its a model that has multiple levels, each level prints at a different temperature. The levels will generally have a bridging test, overhang test and often a small spike to test stringing. That way you can see what works best for your combination of printer/nozzle and filament.

Prints not sticking is usually down to 2 things , initial first layer z height adjustment and bed cleanliness.

The instructions for z height level in this thread https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/ are way better than the built in method (if you arent already using them).

Bed cleanliness there are also a million threads on, although petg on the smooth sheet usually has the opposite problem of sticking too well. Looking at your pic it looks like some localised contamination, most likely the remains of a fingerprint where skin oils transfer to the bed. Normal routine for any printing is to take the sheet to the sink and with plain dish detergent and LOADS of hot water scrub the plate with a clean paper towel and then rinse with lots of hot water until the water sheets off. The dry with another clean paper towel, avoiding touching the surface (handle by the edges only). This removes grease and oils far more effectively than cleaning with ipa does (unless you uses massive amounts).

Then place it back on the printer and print if using PLA and just print. If using PETG its normal to wipe it down with something like windex first to act as a barrier to adhesion or use the gluestick to make a barrier between the sheet and filament.

RE: First layer issue

That's just weird you cannot see the page, as I searched it from google just before pasting the link... maybe because I bought this filament from Amazon so I can still see it from my account, dunno 🙂

Here is a screenshot of the page when I open the link. I've the same sticker on the spool saying PrintTemp 200-220°.

Regardless of what the Amazon page and spool say, is it safe for the printer to increase temp to 240° (and would you recommend it)?

Now regarding bed stickyness, I never have this kind of issues (I mainly print PLA and PETG, almost all from Prusa or Fillamentum) and based on the square samples I've printed in the past, I think my Z is correctly adjusted (I'll run another test to be sure though).

I usually use isoprop for PLA, and small amount of baby powder for PETG. I'll try ideas from your links though, thanks a lot.

RE: First layer issue

Personally I would print at 235+ as every brand of petg I have I print at 245 normally.

Even the official Sunlu webstore is inconsistent. The text says 220-250, some of their pictures though say 205-230. Basically I wouldnt trust anything and use a proper real world test with the tower. Its the only real way to know.

If you print it to hot you will only get more stringing that normal and can manually dial it back a bit. Then adjust your filament profile for future prints.

RE: First layer issue

And the official Sunlu page isn't even showing they sell transparent PETG ... so you have to wonder if this is a real Sunlu product being sold on Amazon.

https://www.sunlu.com/products/new-petg-1-75mm-3d-printer-filament-1kg-2-2lbs?variant=32186013155414

But what I see in the OP photo is a fingerprint on the print sheet that is causing adhesion issues.

RE: First layer issue

I have some of that exact stuff and it's definitely in the 230-235 range and not 210. I think I'm using generic PETG settings. And it, like all filaments is sensitive to having the right zOffset. Do the life z adjust my way linked above with that filament specifically. I think I remember last time I printed with it I had to deviate slightly in zOffset from what I normally print petg with.

RE: First layer issue

I have both my printers busy for the next two days or I would offer to print your model with my normal settings to see.

RE: First layer issue

@tim-2

The fingerprint is actually post print 🙂

I touched it to see how bad it was a,d let it continue. I usually handle the sheet with care after cleaning

RE: First layer issue

@ssill2

Will do another life adjust like you say. But I thought you said in your post that it's not supposed to change with filament? (sorry, beginer here)

RE: First layer issue

@dakiki

Well - it is pretty obvious something was on the sheet before you started printing. A drop of oil, a fingerprint, too much Windex. It isn't anything in the model, the plastic, or the printer mechanics. It 'might' be something was on a bit of filament that somehow made it through the extruder and then down onto the sheet where it then spread out and contaminated adjacent extrusions -- but that's stretch.

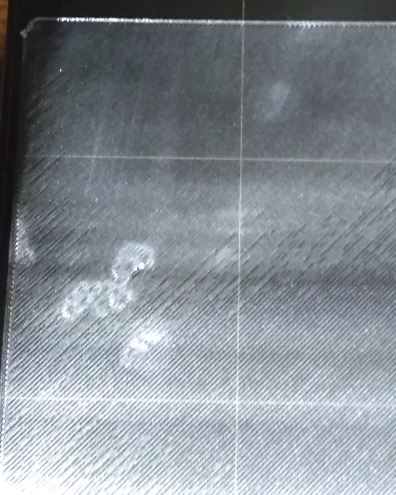

ps: here's what fingerprints look like - and this was after n alcohol cleaning:

RE: First layer issue

@dakiki

every filament can require some tweaks. it's kind of why you want to standardize on a few types/vendors so you aren't constantly having to dork with it. I know in my experience I have to have different steel sheet profiles defined to store zOffset for PETG, PLA, and TPU. I have a roll of ABS coming and I expect might have to mess with that and end up with a different zOffset for that too.

The printer lets you set up to 8 steel sheet profiles. You definitely have to have different ones for the texture and smooth sheets since the textured one is something like .3mm thinner.

Here's how to set them up

https://help.prusa3d.com/en/article/steel-sheet-profiles_1955/

Once you have them set up, the built-in first layer calibration will apply to the selected sheet and thus will remember it for your next print on that sheet.

I have a number of them set up:

Spla - Smooth sheet with PLA

Spetg - Smoothsheet with PETG

Stpu - Smoothsheet with TPU

Tpla - Textured sheet with PLA

and so forth and so on.

RE: First layer issue

@ssill2

Whaa didn't expect fingerprints to produce that kind of behaviour, thanks for the photo and explanation!

I only use 3 types of vendors (including prusa) for the reason you mentioned 🙂

I'll definetely re-run z configuration for my different brands and save them. I only did it once with the original prusa filament I have, and never had any issue prior to using this SUNLU (if it is...) filament.

Thanks a lot for all the information.

PS: The print completed almost OK, even the 1st layer errors were "corrected" by the subsequent layers

PS2: I do remember using the LiveZ calibration posted above, as I did found the gcode on my harddrive and some actual samples I printed last year 🙂 One question though as it would take too long to read 40 pages of posts: Why is the gcode temp set to 170° for PET? Am I suppose to live adjust the temp when printing the square, to match my filament temp?

RE: First layer issue

Oh nwm, the temp changes after initial calibration 🙂

RE: First layer issue

I don't usually use the actual gcode for that life adjust thing. I just create a 1 layer high 75mm square and slice it to gcode. it's good enough it just doesn't do the beeping when you are supposed to change. you just need enough area to tinker with the zOffset until you can get it looking nice. It will remember the zOffset when the square finishes and you should be good to go. I printed a rather flat object in that sunlu clear a few weeks ago now and it ended up pulling up the corners of the plate! but the first layer looked super nice. As I said that particular filament made seemed to do better when I raised the zOffset from what I normally use with my other filaments.

RE: First layer issue

@dakiki

Does the Gcode do a two stage start up, to reduce dribbling and spotting during the Mesh Bed levelling? Like the Mini does by default?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK