Extruder skipping

Hi all,

I've having an issue I never had before on my MK3S and I'm not sure what to do (more than I already did).

I'm have extruder skipping when printing a Recreus Filaflex 82A, although I consistently printed with that same roll before. The roll is kept in a sealed, temp/humidity controlled box, and the roll is not older than 6 months.

I successfully printed a lot of small things with that roll without a single extruder skip (It's actually the first time I've seen my printer skipping steps). I'm now printing a new model, with the same filament settings (1st layer 230° and bed 50°), but probably not the same slicer/fw version as it's been 5 months since the last time I printed with that filament.

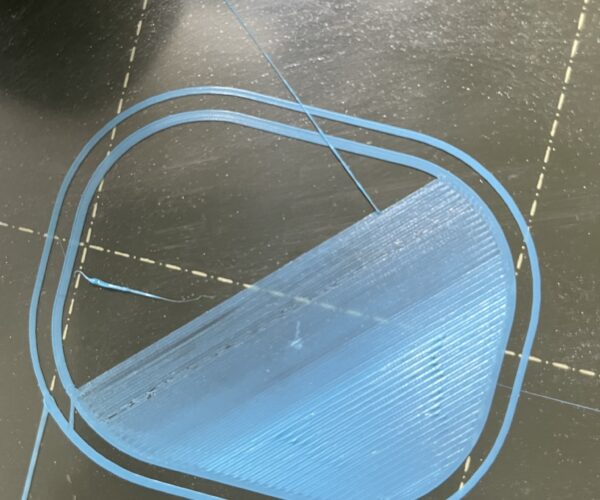

So what I have now, is each time I start this print, it always fails during the 1st layer but not immediately (after 1 or 2 minutes), the extruder starts skipping and under extrusion can be seen on the first layer (see photo).

I cleaned the nozzle, cold pulled a couple times without any visible residual material, thightened/loosened the door screw to see if it made any difference, but nothing changed. I printed some other models with another filament inbetween tests, without any errors or skips.

I kind of understand skipping can occur if the presure in the hotend is too high, but I don't see why it would appear suddently and so consistently.

Here is a picture of the first layer right after I cancelled the printd, we can clearly see when it starts to underextude (matching when I hear the skips)

Any idea on why, and how to solve?

Thanks a lot, good day!

RE: Extruder skipping

Have you tried slowing down? Also drying the filament? I print a different brand of 82 hardness TPE and find I need to loosen the extruder gear spring, dry the filament and print around 20mm/sec.

A plastic bag and dessicant will slow down but not completely prevent moisture being absorbed by your filament. It helps but isn't a complete solution.

RE: Extruder skipping

Hi,

like I said, I keep all my rolls in a sealed box full of desiccant (around 20% humidity, 20-24°). Also like I explained for the tests I've made, I've tried to loosen/tighten the screw with any change (well, tighten tends to cause more skips, as expected).

First layer is already set to 20mm/sec anyway, so I cannot slow more. I never had any issue with that filament (in the past), that's why I'm wondering if there is something wrong with my extruder/hotend.

I encountered something similar today, when printing another model using Filamentum PLA. I printed twice the same model, and at the exact same time and location (on a 3h print) I had extruder skips. I never ever had any skips on classic PLA (nor did I for any plastic I printed for that matter) before. This model was slicer with PrusaSlicer v2.4.0, and it looks like the skips occured during the ironing phase, maybe it's normal, I don't know, but I find the coincidence a bit troubling.

I did another cold pull, and used the acupuncture needle to clean the nozzle inbetween the 2 prints just to be sure, no change.

RE: Extruder skipping

Just my two bits worth. I print in the tropics. The work area is climate controlled. Filament is in sealed bags with dessicant. It still gets wet. Plastic bags only slow down moisture transfer not stop it. When I encounter problems like this the first thing I do is run the filament through a drying cycle and most of the time the problem disappears. Try using PVA+. In the sealed bag with dessicant it's so extremely hydroscopic that even a week of storage will require drying.

You can print slower. I've had some TPE that I printed at 10mm/sec for first layer and then 15mm/sec after that to get a good quality print.

I find with my material and printer I have the screw backed off until it is just below flush on the not and that small adjustments make a lot of difference with some filaments.

Good luck.

RE: Extruder skipping

Just my two bits worth. I print in the tropics. The work area is climate controlled. Filament is in sealed bags with dessicant. It still gets wet. Plastic bags only slow down moisture transfer not stop it. When I encounter problems like this the first thing I do is run the filament through a drying cycle and most of the time the problem disappears. Try using PVA+. In the sealed bag with dessicant it's so extremely hydroscopic that even a week of storage will require drying.

You can print slower. I've had some TPE that I printed at 10mm/sec for first layer and then 15mm/sec after that to get a good quality print.

I find with my material and printer I have the screw backed off until it is just below flush on the not and that small adjustments make a lot of difference with some filaments.

Good luck.

I am in the SE USA and I have the same habits. Stuff just gets wet.

--------------------

Chuck H

3D Printer Review Blog

RE: Extruder skipping

I don't have such issues, my box is sealed, has an hygrometer and a PTFE tube from the box to almost the extruder.

I think there is something else going on here but don't know where to search (and if possible I don't want to dismount the whole extruder :x)

RE: Extruder skipping

Good luck. It is an extrusion issue. A partial clog is likely the culprit. Most common causes are wet filament, the nozzle is too close to the bed, dust particles on the filament, diameter of the filament is very inconsistent, or hotend temperature is inappropriate(too high or low). What you do with it is your business.

On this forum, most of us speak from experience and I would agree that hydration is a common cause.

--------------------

Chuck H

3D Printer Review Blog

@dakiki Humour us: dry it first. If it still glitches you've lost nothing but a little time - some filaments can become noticeably damp within the duration of a print; good at the bottom bad at the top, it really is one of the commonest causes of issues especially once the central heating is turned off.

Cheerio,

RE: Extruder skipping

Good luck. It is an extrusion issue. A partial clog is likely the culprit. Most common causes are wet filament, the nozzle is too close to the bed, dust particles on the filament, diameter of the filament is very inconsistent, or hotend temperature is inappropriate(too high or low). What you do with it is your business.

On this forum, most of us speak from experience and I would agree that hydration is a common cause.

Thanks for the input, I do understand there is no perfect answer as each case is different even if some symptoms are identical.

I'm trying to understand what is the most possible cause (and solution), and excluded moisture as I've the setup recommended by CNC Kitchen, with a sealed box and a small sponge wipping the filament to remove dust.

I thought of a partial clog as well, that's why I used the needle from nozzle and cold pull to clean the hotend, is there something else to unclog?

I will try to raise the nozzle, this indeed might be something that changed since the last perfect prints I had with that filament.

Don't get me wrong though, I really value your comments, I'm just trying to find the most probable cause for my setup as I've already taken steps to prevent some common issues (like moisture issues).

RE: Extruder skipping

@dakiki Humour us: dry it first. If it still glitches you've lost nothing but a little time - some filaments can become noticeably damp within the duration of a print; good at the bottom bad at the top, it really is one of the commonest causes of issues especially once the central heating is turned off.

Cheerio,

Thanks, will do another drying of the filament (already done that 2 days ago), like you say it doesn't hurt. I do agree that near the end it can get messy, especially if your filament is exposed to moisure for too long. In my case, it's just after 1 or 2 minutes, that's what is perplexing.

Thanks a lot, I'll report any progress for future reference.

RE: Extruder skipping

So,

I dried the filament for 6h in my filament dryer and tried another print, it failed during the 1st layer like before. Just slightly different failure: yesterday I heard the extruder skipping before seeing less material on the plate. This time, I saw less and less material, then when there was almost nothing extruding did I heard the extruder skipping. So nothing changed.

Then I tried what you suggested, I raised the nozzle a bit more and it was successful on the first try.

Thanks all for your help, Z it was 😉

RE: Extruder skipping

Hi dakiki,

perplexing it is indeed. The whole clicking business can get very annoying. I recently went through the same story.

Analyzing it let to basically three potential problem points.

Upstream, gears and downstream (sound simplistic but I like to break down my problems as simple as possible).

Upstream means that there is too much resistance from the roll and the gears can not produce enough force to pull the filament from the roll. Easily checked for and if it happens it seems more random than what you report.

Gears as such. Of course the classic of the loose grub screw and the driven gear skipping on the motor axis. I assume you've checked this hence I included it only for completeness. Next on the list are dirty or worn gears, dirty is common worn is rare but not unheard of. I don't know any way to test for worn gears, sorry. Third gear related problem is the idler tension. My personal rule of thumb is, the softer the filament the less tension. For flexible filament I have the tension screw only far enough in to just grab the thread of the nut.

Downstream: that's as stated already the whole story around pressure build up. Moist filament contributes and is easily sorted (curious to read about your ongoing filament drying test). I had an unnoticed partial clog that I tried to fix with numerous cold pulls. The pulls looked acceptable and must have removed enough of the partial clog for the next print attempt to start fine only to clog up again. I was able to fix it with the acupuncture needle, which you have tried as well. But, and I think this might be part of your problem, my clog consisted almost completely of PLA, where yours might be TPU/TPE. Rather sticky stuff, so maybe there is still residue in the nozzle after the needle clean or the needle just pushes the residue into the wider bore of the nozzle. Enough to restart the accumulation and clog cycle. The fact that it became independent of the filament type used, seems to support that hypothesis.

My only idea how to find out if that's the case would be a fresh nozzle. If that fails the only remaining conclusion would be that something changed with the filament in the 5 months it was sitting in it's box.

I hope that helps and didn't come across too smartarsey 🙂

Cheers

Hansjoerg

RE: Extruder skipping - post scriptum

me again... edit window just closed

I forgot to mention what lead me to the suspicion of the partial clog. When manually pushing the filament through the extruder for the cold pulls it took way more force than it normally would. I then measured the extrusion that was freely dangling from the nozzle and it was only about 0.25mm thick. I assumed that even the stretch that happens when the extrusion is pulled by it's own weight wouldn't make it that thin and that gave me the idea of the partial clog.