Extruder Crashing/Knocking Print off

Hi all. Thank u for letting me join, I am an absolute newbie and I really need some help. I've had my printer for 3 weeks now and I cannot seem to successfully print anything at all. Sorry if this is annoying question.

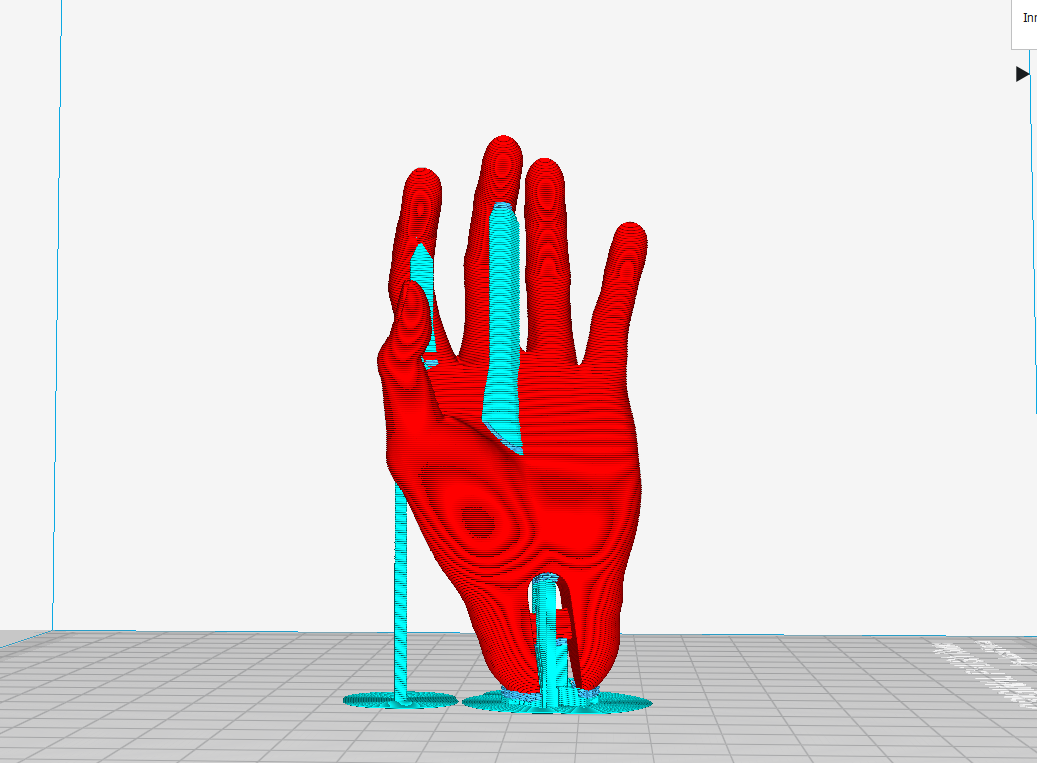

There is this hand structure I'm trying to print.

I attach a picture of it sliced using CURA 3.4.1 and my settings below.

The problem I have is that at about 43% the extruder seems to knock the entire print off to one side. Also I cannot seem to print that thin support tower beside the thumb straight, I attach some photos showing how it’s always skewed.

My first attempt, I had the bed plate temp at 60 and one side of the brim started to lift after the extruder dragged the top of this tower in the middle of printing. So second attempt I raised bed temp to 75 and that seemed to stick down well, however still at around 45% the extruder just knocked the entire print off to one side. I didn’t exactly see it when it knocked it, but when I came back to check on the printer, I just saw that it had been knocked aside. Why and how did it do that? Everything looked level as it printed up, except for that thin tower that seemed to skew whichever way as shown in photos.

Aside from this hand I’m trying to print, I have other organic sculptures and the same thing would happen, mid way through print, the extruder would either drag on the very top layer or the side of it would knock against a structure and everything failed.

Second question, when I tried to remove the support material, wow they are stuck to the print soooo hard. Even with pliers some of them I cannot remove at all.

Thirdly, I noticed there is this vertical banding lines happening all over the hand. Is that normal or is that an indication of something else gone wrong that might explain why this is happening??

Please help? I’ve got a friend who has a Creality CR-10 and they had tried printing similar hand in same orientation as me and same support structure and they were successful, the extruder didn’t knock anything off and the thin support materials printed dead straight up whereas mine is all just wonky.

A couple more photos in post #2

Material = PLA

This is the filament: https://www.ebay.com.au/…/1-75mm-3D-Printer-F…/302764467386 …

Layer height = 0.1mm

Initial layer height = 0.2 mm

Line width = 0.2 mm

Wall line count = 2

Compensate wall overlaps = yes

Infill density = 15%

infill line distance = 5.333 mm

infill pattern = grid

Default printing temp = 200

Printing temp initial layer = 215

Final printing temp = 200

Default build plate temp = 75

Diameter = 1.75 mm

Flow = 100%

Retraction distance = 0.2 mm

Retraction speed = 35 mm/s

Print speed = 45 mm/s

Infill speed = 170 mm/s

Wall speed = 22.5 mm/s

Support speed = 45 mm/s

Travel speed = 180 mm/s

Z Hop when retracted = yes

Z Hop only over printed parts = yes

Z hop height = 1 mm

Fan speed = 100%

Initial fan speed = 0

Support = everywhere

Support pattern = zig zag

Support overhang angle = 50

Support Z distance 0.1 mm

Support X/Y Distance = 0.7 mm

Support Distance priority = Z overrides X/Y

Minimum support X/Y Distance 0.2 mm

Support Stair Step height = 0.3 mm

Support join distance = 2.0 mm

Support horizontal expansion = 0.2 mm

Support infill layer thickness = 0.1 mm

Use Towers = yes

Tower Roof angle = 65

Build plate adhesion type = Brim

Brim min length = 250 mm

Brim width = 8 mm

Brim line count = 20

Thank you.

Re: Extruder Crashing/Knocking Print off

I to am new to 3D printing, but learing quick.

I think you are trying something far too hard without understanding your printer. You need to learn how to set it up for the use you want.

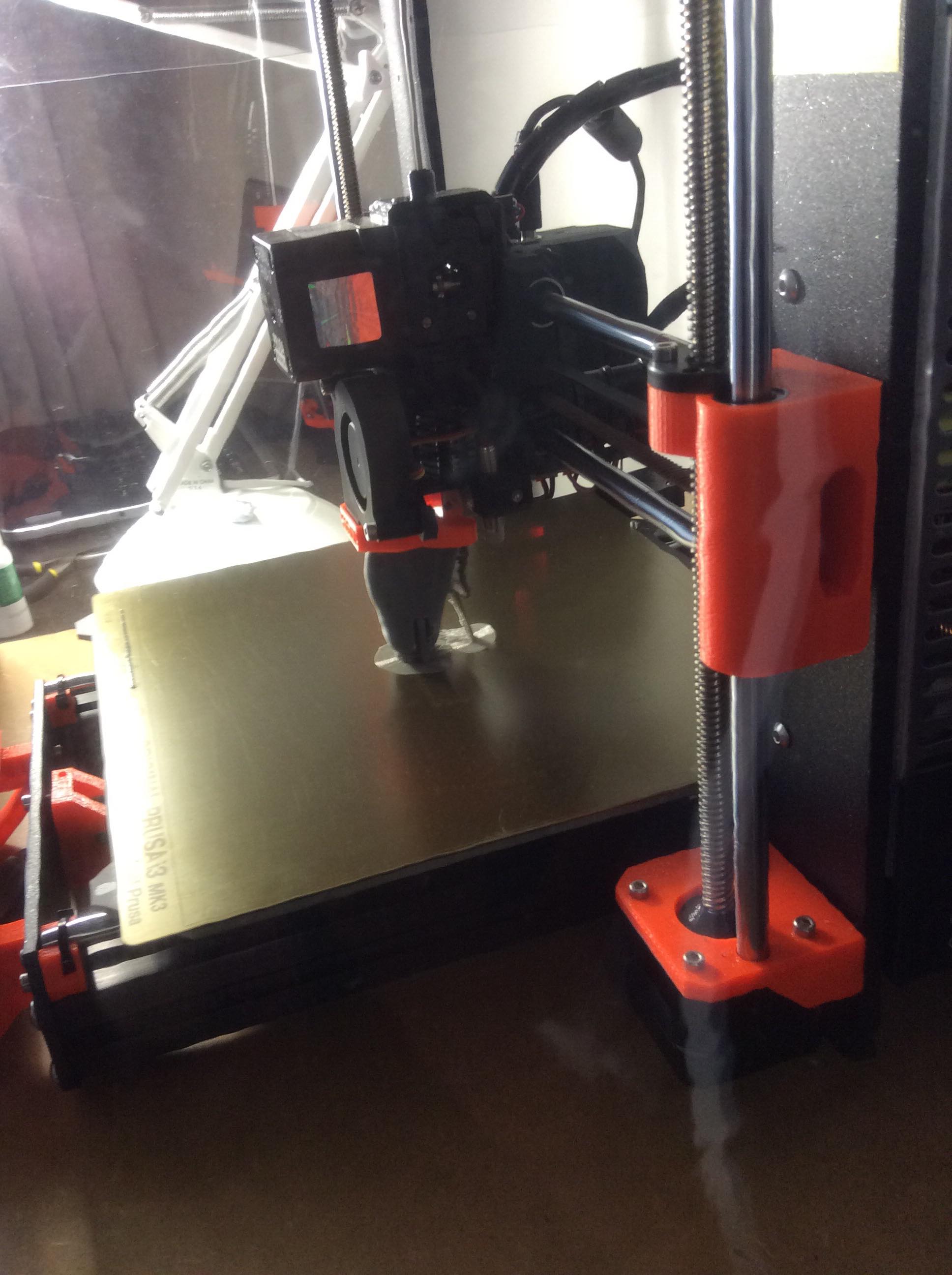

It will need tuning to the filament that you have. If you have the Prusa PLA then try the same print but with either the Prusa control or Slic3r PE as there have the default Prusa PLA settings. I had lots of good technical prints using just the basic Prusa control slicer.

One thing i have learnt recently after doing a PLA print of a wheels centre cap(Looks like a dish) is the need for PLA to be cooled well. I had no idea of the limits of overhangs and just set my print away. It did print although poor surface. I have since managed to get it far better by reducing the bed temp to almost off , you will need something to aid adhesion to the bed with this. Also i have done the update to the part cooling fan with the new nozzle and the 45 degree mount.

The support tower may have bee printing at too high a speed and with the tempreature of the filament is may have melted and warped, again better cooling.

This is the first print with overhang i did to copy the centre cap. I have since altered the settings and got a far better print to the surface

As to the print being knocked off thats what will happen if you dont get the setting correct for all the above. The base area stuck to the bed is not able to hold the force of any slight knocks of the nozzle to the print. Remember the filament can drag slightly on the print if the extrusion volume is not perfect to the amount the slicer has been set to print. Under extrusion will pull on the printed part and flex the first layer and its adhesion to the bed.