Eliminate Banding on dome print

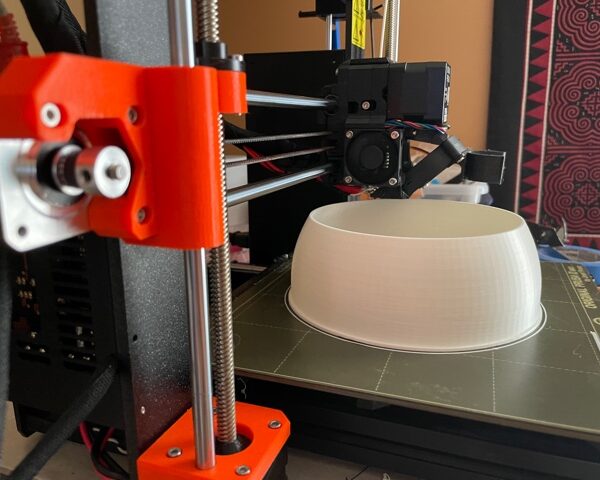

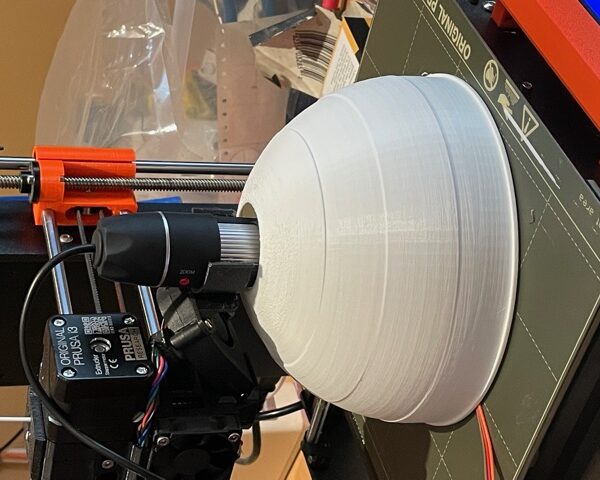

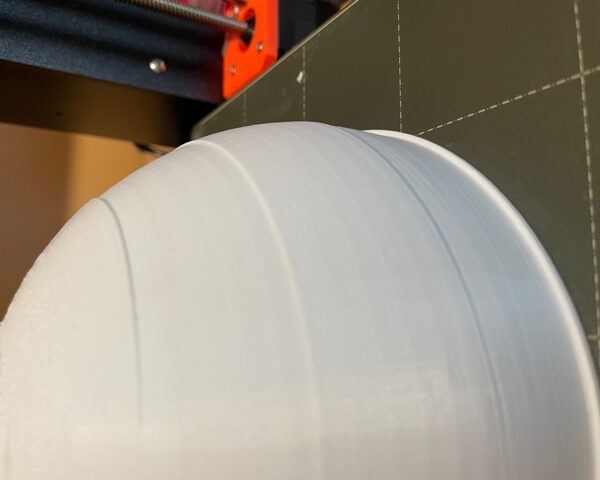

I printed a dome light diffuser (about 160 mm diameter, 100mm high) and about every 25 mm (not exact) there is a shift in in the y axis by about 1.5mm or so. (see image) Made from ABS, shell is about 2 mm thick. Printed on a 6 month old MK3s printer I assembled myself, the belt seems tight (how can I quantify tightness ? ). But if the belt were loose I wouldn't expect the large jumps at somewhat regular intervals. This is the first time I have printed anything this tall.

Here is link to 3mf file.

Note the image is with my USB microscope clipped on a mount I made so I can use printer to do image stacking in a controlled way for taking pictures of insects. There is a ring of LED lights under the dome perimeter.

RE: Eliminate Banding on dome print

Those are layer shifts caused either by bearings seizing, or the sleight chance your axis drive gear is not properly attached to the motor shaft.

Questions:

- Did you clean and grease your linear bushings before you installed them?

- Did you use the FLAT FIRST technique when tightening the set screws on the belt drive gears?

If the answer is no to these, you need to go back and redo these steps.

And please post any attachments to the forum - not some foreign site most of us can't use and subjects everyone to trojan attacks.

How to save and upload a project

RE: Eliminate Banding on dome print

Totally agree with Tim

RE: Eliminate Banding on dome print

I checked the set screws and one was in the flat and both were tight. But I did notice that the pulley was flush with the shaft end. This brought the belt very close and probably touching the side wall of the servo and bearing support. I pushed the pully towards the servo a few mm and the belt now clears the support. I remembered that I had printed a 20 mm diameter cylinder that was 120 mm high with no banding a few months ago. My guess is that the belt occasionally caught on the wall when the x travel was near the extent of the travel when I printed the larger diameter part.

Thanks for the help, problem solved !

(also thanks for tip on uploading 3mf files as zip archives... but curious why 3mf files can't be natively uploaded using 'add media' which I tried at first)