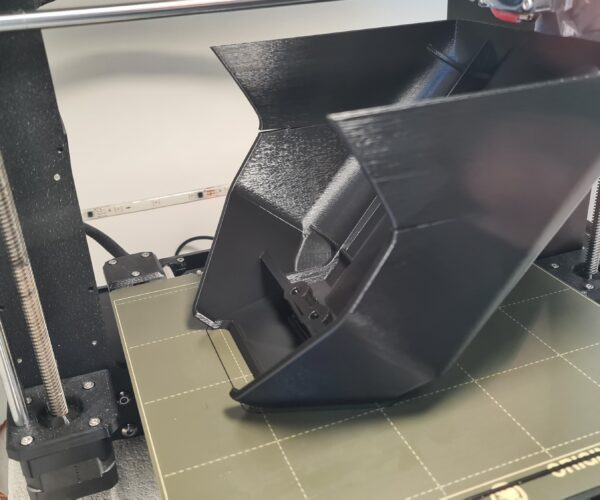

Cracks always at the same spot // 16 hour print

Hello,

iam out of ideas.

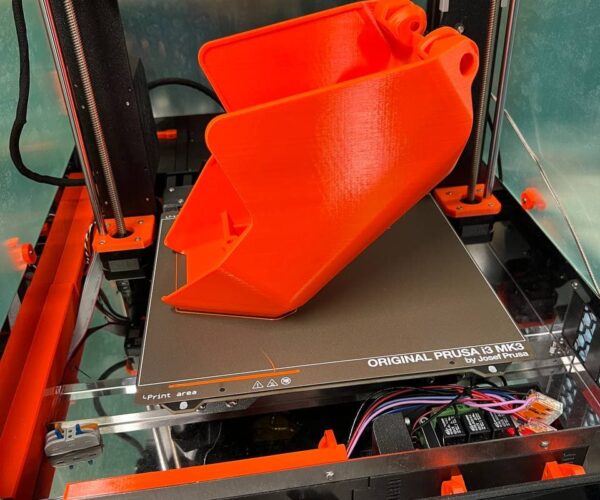

I printed this

4-5x PLA -> no Problem

2x Petg (Sunlu) -> no Problem

3x Petg (Sunlu) -> crack

1x Petg (Bavaria) -> crack

1x ASA (Bavaria) -> latest from pics -> crack.

ASA was printes with 260/110°c in an enclosure with 42°c constant inside.

what could i do?

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE: Cracks always at the same spot // 16 hour print

i cant do that public. i will send you a pm.

I'm not the only one here who can diagnose a .3mf and for most cases I am not the best.

Here's what I would look for:

Stupid settings like ultradetail layers and 100% infill, unsuitable infill patterns - cubic would be my first choice here, walls too thin to take warping stresses - thicken the walls enough to accept additional perimeters, and other non standard temperature and speed settings to no purpose.

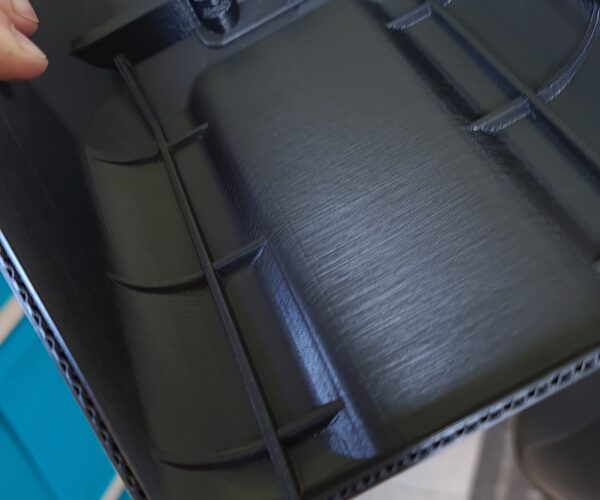

Also shapes that naturally induce uneven stresses, a few slots or offsets to break up very long filament runs can make a huge difference to warping.

In your case I suspect there is too much mass in the right hand side as you are printing it...

Is this a replacement for an injection moulded part? If you are designing from scratch chamfering away some of those curves might reduce the stress propagation.

Cheerio,

RE:

I tried 0.3 with 0.4 nozzle at 15-20% infill + 0.4 layer with 0.6 nozzle.

Gyroid pattern. Reduced speed in the last fail also. limited max volumetric speed to 4mm³ also

2 perimeters now. since a 3 perimeter model cracked also.

changed the nozzle to a nickel plated copper one too with higher temps (265/115)

ill try right now another PETG Filament. A buddy had success with stock (petg)Prusament/Settings