Burning & Blobbing

I need some major help, I feel. This printer is a home based business printer for my wife & I. With it down... we cannot pursue some new jobs with clients.

i3MK3s (KIT), no enclosure, located in my home office (typical HVAC comfort), no upgrades/additions/after market add-ons... all is factory. All filaments are Prusament and were factory sealed.... all spools are less than 2 months old.

Printed supplied PLA perfectly...the entire spool has been used, amazing print quality. Switched to Prusament PET-G (black)... 1st print was perfect... used about 2 1/2 cubic mm on that first job..... then everything afterwards has failed. See 3 attached images (these are NOT the worst it's been, these are the minimal issue failures). I have not had a single successful PET-G print since the first one was done. Have not yet switched to another filament but plan on it (Prusament PLA).

The prints are:

1) not sticking to the beds (tried smooth bed, bought a textured bed to try... both beds fail to hold the print). No Z adjustments were made from PLA to PET-G that would cause this. Have ran Z calibration numerous times... have live adjusted Z from -0.99 to -1.18..... no effect on the sticking issue. I keep the Z around -1.08... that seems to be the optimal bead shape for this machine. I have performed a cold pull of the filament, checking for clogs and debris.... it's all clean. Every calibration test is successful.

2) appearing as though they are being "burnt". There are pieces of excessively melted material being extruded into the build and randomly deposited onto the build plate. There appears to be no "smoke" or smell beyond normal (so far). During the print.... the extruder creates some strings, excessively, as it leaves a print location..... and I believe that is contributing to #1 because those "strings" cake up onto the print and nozzle, stick to other strings and printed areas and drag previously printed areas with the head.... causing a collision later.

3) I have made adjustments to the factory PrusaSlicer settings for retraction, nozzle temps, bed temps, etc. So far... nothings seems to have an impact... which makes me believe that this is NOT a settings issue and is a hardware issue but I honestly have no idea where to start. I have a single spare nozzle from Prusa that I thought about trying... not sure if it'll matter.

RE: Burning & Blobbing

Check if blobs are not coming from above the nozzle, is there some leak, if nozzle is not good installed it can leak.

To print good you need 2 things:

1. clean bed, use dish soap a few times with hot water, dry it and start printing. Alcohol does not clean as good, you can use a few times alcohol, but cleaning with dish soap is needed.

2. First layer calibration, see movie,

Both 1 and 2 are needed to get a good print and to get good sticking to the bed.

I was printing and had stringing and blobs coming of the nozzle (petg),

Solved this through lower temperature nozzle 5 lower(235), and extrusion multiplier lower with 0.3, then stringing and blobs did go away.

Try this with your print. Both settings you can adjust even if the printer is working.

RE: Burning & Blobbing

What does the nozzle look like when it's printing or after printing? When it is laying down the plastic, do you see it dragging the filament along with it? The first layer looks stuck down, but it looks like the subsequent plastic is getting dragged around. Hot PETG is very sticky and will stick to your nozzle if too close. I back the live z by about -0.02 for PETG.

If it is not sticking down and your nozzle is covered in plastic, it's too low.

If it is not sticking but your nozzle is clean, then too high.

Try switching back to PLA for your next print to see if the issue persists after filament change, you can therefore eliminate whether it is a hardware issue.

RE: Burning & Blobbing

I would suggest readjustig Live Z, the Nozzle appears to be too low, and is ploughing through the surface of the filament

I use the Life Adjust 'Z' My Way, process...

https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

kind regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Burning & Blobbing

Sorry for the delay in responding.... been a busy few days and my whole family has been sick.

So... the nozzle, at the start of the print, is clean and shiny brass. After a few passes (literally only about 8-10 inches of travel) there is severe stringing from the nozzle. If I am NOT able to babysit the printer... that stringing will begin to catch on the nozzle and cake up...creating a film on the brass nozzle....so the nozzle begins to darken in color. Simultaneously.... that same stringing begins to catch on other areas of printed material....which eventually leads to a collision and printed pieces get ripped from the bed. I have closely watched the printer nozzle and have performed many LIVE-Z adjustments to make sure the nozzle is clearing the printed filament beads.... and it is. The nozzle has plenty of clearance after printing.... honestly I could probably adjust it to be closer but if I do, this problem of catching and hitting will worsen.

I have switched back to a PLA and the problem persists there as well. I've done LIVE-Z adjustments with the PLA... no effect to reduce the issue. I've adjusted temps +/- 10 degrees on the bed... no effect.... +/- 20 degrees on the material (PET & PLA).... no effect. I have yet to get time to change the nozzle out but I hope to do that tonight or Wednesday before Thanksgiving. The more I play around with this.... the more I suspect hardware because no software adjustments seems to make a noticeable difference. Up until this point.... this printer has printed phenomenally! Super impressed by the quality of the print. This is what makes me think something internally has moved/shifted/etc to cause this.

I have ordered a silicone "sock" for the extruder head to see if that helps with the sticking issue.... but I know it does nothing for the strings that are coming from the nozzle itself.

Thank you all for the replies and please keep them coming if you think of anything else I can adjust or investigate. I'm running out of options of things to try.

RE: Burning & Blobbing

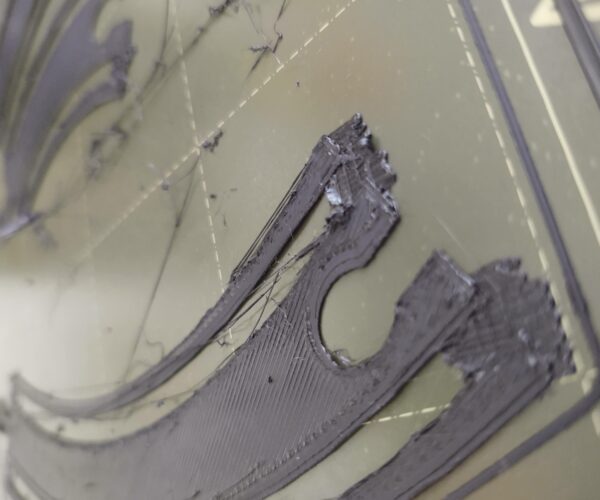

Notice images 03.jpg & 04.jpg.... this is exactly how it printed and "bubbled" up. Also notice that the *start* of the print shown in 02.jpg is perfect! Bead height is attempted to be displayed in 04.jpg along with the bubbling. It's almost like certain rows or certain beads are at issue but the area of the issue is random. I can print the same model in a completely untouched area of this new textured bed... and the issue will still exist, sometimes in the same area of the model... sometimes in a new area.... many times in both! I am so confused.

RE: Burning & Blobbing

For some reason, on that last response I posted, the beginning was omitted.

Joann... thank you for posting that link. I ran the calibration print *AFTER* I installed a new nozzle (from Prusa). This was printed on a new (75% surface area never used/touched) textured plate from Prusa. No matter where I place the print job on the bed... it has issues... so my guess is that it is *NOT* a Z axis bead height issue (I could certainly be wrong but it just does not add up to be the issue).

RE: Burning & Blobbing

@kendred

The pictures in the post above suggest that the nozzle is too low, (Live Z too large a number)

please try again

As the print runs, try reducing the Live Z number and observe the surface of the print, it should be smooth on the surface with no ripples

You're close but not yet right.

Good luck,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Burning & Blobbing

Can I just say whats been a success for me is the old glue stick. I get the impression from the web that this means you are a failure, bit its certainly works for me.

RE: Burning & Blobbing

My 2 cents, the textured sheet is utter garbage. I could not get PLA or PTEG to stick to it properly. PLA is to be expected, if you print PLA, use the smooth sheet.

However for PTEG the textured sheet is recommended. But I could not get a print to stick to it for more than a couple of layers, even though the sheet was clean and the 1st layer was perfect. I had to use http://www.dima3d.com/en/home/dimafix/ , with it the PTEG sticks.

Having said that, in your case I would follow Joan's advise. Your nozzle seems to be to low.

RE: Burning & Blobbing

This will sound crazy as well, but the tube of stick glue they put in with the prusa kit is the best. I tried a branded 'pritt stick' no where near as good.

RE: Burning & Blobbing

All,

I greatly appreciate all of the feedback... I truly do. This forum is fantastic. I wanted to update you all on the progress so far. I received some silicone socks today so I installed one of those onto the heater block... fits perfectly and shows no area of interference. I thoroughly soaked my textured bed in Dawn last night... scrubbed it good and let it air dry over night and this morning. I just tried to run a print and stepped out for maybe 20 minutes... attached is the result. Chaos and catastrophe. While the silicone sock did exactly what I was hoping (no material is stuck to or around the nozzle heat block)... the socks did not prevent the issue (I was hoping that somehow they were the silver bullet). I have not yet tried the glue stick... that's coming in a few minutes, just as soon as I find the one they sent with the printer. The nozzle is *still* stringing during the print process and I believe those errand strings are causing excessive build-ups in areas that eventually catch portions of the print head and then it becomes a 50 car pile-up on the highway. I did make an adjustment to my Z... changed it from -1.125 to -1.02 and that does seem to have helped a lot on the calibration print.... it does not seem to be helping with the actual prints.

RE: Burning & Blobbing

Yikes! This shouldn't be so hard and you're having a nightmare. Sorry you are going through this.

How's your assembly, anything loose? Do you have play/wiggle in your X-axis or Z? A printer that was working for a little while, and suddenly is all out of happiness sounds like something either physically happened to it (injury) or something loosened up.

good luck,

Christopher

RE: Burning & Blobbing

Try the glue stick (luke)

RE: Burning & Blobbing

I have to agree with bove. Everytime I have had blobs, it has been leaking between the heatblock and heatsink.

--------------------

Chuck H

3D Printer Review Blog

RE: Burning & Blobbing

Okay... possible success.... I used the supplied glue stick, applied a liberal coating... smeared it out move evenly with my finger.... started a print and so far... the Z-axis has printed a full 1" (25mm) high area of a 6" x 6" (152mm x 152mm) model.... without any detachment of the printed layers, without any blobs on the print bed or within the model... and so far (crossing fingers, knocking on every piece of wood) everything is working perfectly. The model looks beautiful so far.... it's got another 8 hours (about 2" taller) to go before it's finished.

Thanks to all for posting so many helpful and welcome suggestions.... you folks are awesome!

RE: Burning & Blobbing

I'm resurrecting this thread because it seems to be close to the problems I'm having.

I've printed for a few months with my I3 MK3S, generally very successfully, using PLA on a smooth bed. I used the PLA the printer came with, and black PLA from SUNLU. (I don't know if it's as good but I had few failures.)

I switched to translucent SUNLU PETG, and I had to change the live Z, and slow down the first player printing a lot, but I got a few successful prints, some of them tall, thin and tricky. There was some threading but it was manageable.

Suddenly things got sketchy. I reprinted a model and it failed part way up. I tried again and it failed in a different place. Both times it looked like a blob had come out, things got tangled, etc. Things quickly got worse, now I can't even get through the First Layer Test without the initial deposits failing to stick and the square at the end looking bubbly; if it gets that far. Often now it doesn't - the deposit will be dragged along or just stick to the nozzle and the nozzle gets completely covered with goo. I've tried Z adjustments between 0.0 and -big numbers; nothing helps.

I clean the bed with 99% isopropyl and treat it with pure acetone. I've recalibrated the printer twice. I've cleaned the outside of the nozzle with steel wool, tried a higher first layer temperature, fiddled with live Z and cut the first layer speed dramatically down. Nothing helps; prints uniformly fail on the first layer with filaments dragged away and a nozzle covered with hot goo. I'm skeptical about using the glue stick - I never needed it for PETG before and these are the same models that used to work fine.

I'm curious about the idea that the nozzle itself could be leaking. My eyesight isn't great and I don't see how I could possibly get a view of the nozzle while it prints, so how do I check for that, and what is the fix? I don't use abrasive filament (always PLA or PETG) so I would not expect the nozzle to go bad, at least not in the few months I've had this.

Really need the help, this project is supposed to be done by Christmas... Thanks!

RE: Burning & Blobbing

Hi. I just left a customer review on amazon for sunlu filament as being the worse to date I have tried. I did not get a single good result out of it and wonder if amazon has been infected with counterfeit, or if infact sunlu just has terrible consistency.

Long and short is before you blame anything else, blame that!

RE: Burning & Blobbing

@nazev

And sadly this tends to be the attitude from the internet in general. The fact is I have cleaned my print bed so well you could perform surgery on it, its still does not stick. I have no doubt the ambient temps have a play in it as well the preconseption that I am wiping my snot all over the print bed for some reason.

The glue stick so far as I can tell causes no harm (aside from perhaps having to wipe it off with some detergent afterwards) and offers only benefits. For beginners like me I am struggling to understand why it is bad other than some notion from those more experienced that they can do without it. But I also note those with a lot of experience seem to give whole rooms with temp controls and everything else to get the results they enjoy

For the rest of us in the real world, a 90p stick of glue work wonders!

RE: Burning & Blobbing

After reading here, I realized I'd never seen advice about dish soap to wash the bed, and decided to try it. Other changes were (yet more) fiddling with the live Z, and changing the model to have more stability as it prints. The bed looked shinier after washing, so I'm assuming some sort of layer got on it that the alcohol didn't remove. Lesson learned.

The first layer still didn't come out great, but it was much improved. So far the rest is printing ok, but it will just take one blob to prove me wrong. Luckily for this model the first layer isn't going to be visible.

And ok, so SUNLU is sketchy. The stuff that came with the printer worked better, as you might expect, but I'd like to buy from a source closer to home with cheaper shipping if possible. What do people have success with, for PLA and PETG?