RE: Bulging corners

@bobstro

Will post end of the week (not at home right now) some pictures of test patches I printed to judge the z level. They look OK to me. I always clean the bed with 99% isopropanol before every print. Also tried both sides. Will do a test the PEI sheet I put aside after I got the powder coated sheet a couple of months ago.

Juergen

RE: Bulging corners

Here's the project file again: tile.zip

It's the same model as the one on my second picture.

I will check if my extrusion multiplier and linear advance are still good. Maybe something has happened to my extruder.

RE: Bulging corners

There's something weird with my extruder. I checked steps/mm and found that it extruded too little. I calculated new numbers, but now it extruds too much.

I think I need to fix this first, before I continue with the troublshooting of my corners.

RE: Bulging corners

There's something weird with my extruder. I checked steps/mm and found that it extruded too little. I calculated new numbers, but now it extruds too much.

I think I need to fix this first, before I continue with the troublshooting of my corners.

Are you using the extruder calibration procedure on Mattshub? FWIW - I have read that this procedure isn't really necessary for Prusa printers given the uniformity of the build. With other "more random" printers, it's essential, but done properly, you can expect to come up with a deviation of 1-2% at most. Considering that you've had problems since completing this procedure, I'd suggest resetting the value to default and testing again. 280 steps is the default, IIRC. After going through this procedure, I would up with 282 so didn't bother with it.

What is worth doing is a calibration for each new filament type. Prusa has a simplified approach. While your firmware settings define a baseline extrusion rate, this procedure identifies minor corrections to your extrusion multiplier for each filament. This helps with ooze and stringing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bulging corners

Yes, I'm using the procedure from Matt's Hub. I have it set to 283, but when I extruded 100 mm, I only got 90. I tried it two more times and both times I got 100 mm. Maybe the first time was just a random glitch.

I'm going to try the extrusion multiplier procedure next. I have done it before (came up with the number 0.98), but that was with a different filament brand. I'm doing it now again with the current brand. I will bring the print to work tomorrow and measure it using our calibrated caliper.

I've also made sure to clean out the nozzle. I did several cold pulls and removed quite a lot of old filament residue. Don't know if it's related, but quite often the last time I've had to clean the nozzle with the needle in order to get a smooth stream of plastic from the nozzle.

RE: Bulging corners

Well, our micrometer was out to be calibrated. I used one of our regular calipers instead and it shows 0.45 mm.

I'm going to try printing the object again and see what it looks like. Maybe try with an extra perimeter.

RE: Bulging corners

Well, our micrometer was out to be calibrated. I used one of our regular calipers instead and it shows 0.45 mm.

If that's the measurement for a single wall and you used 0.45mm perimeter widths, that's a pretty good result!

I'm going to try printing the object again and see what it looks like. Maybe try with an extra perimeter.

As a test I'd slow it down 50% to see if it helps. If it does, you know you can fix the problem with slicer adjustments.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bulging corners

Well, I tried it with three perimeters instead of two and I also tried it at 70% speed. No change.

I think I will try to print just the upper half of the object. To see if it's somehow related to the Z-position.

RE: Bulging corners

I tried printing the object using the stock settings in PrusaSlicer (Generic PLA). The only change I made was to increase the bed temperature to 70º in order to prevent warping. The corners still look the same.

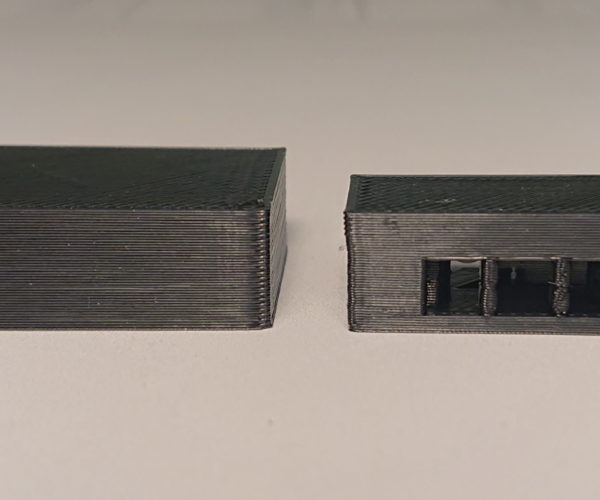

I cut down the original model to a depth of 1 cm to speed up the test prints. I also printed a simple box with the same width and height as the model I'm trying to print. This box came out perfectly for some reason:

I have no idea why my model shows the bulging in the upper half of the corners, but not the box. Both prints were made with the exact same settings.

The bulging is much less now than with the first print I made, but I still find it very odd.

RE: Bulging corners

Part of that corner bulge looks to be from the z-seam placement. If you put the z-seam in a corner (using Print Settings->Layers and perimeters->Advanced->Seam position) with Nearest or Aligned, it will pick a corner. Try setting it to Rear. This may look uglier withe a visible seam on the rear of the print, but will keep the seam out of corners so you can see whether that's your primary problem.

The main difference in parts is that the solid box is made up of mostly sparse infill with solid top and bottom layers, versus the part with opening being made up of varying density. If your filament settings don't match your slicer settings exactly, this can happen at transitions. A combination or extrusion rate, speed and wall thickness usually dictate these results.

What do you have your extrusion multiplier (Filament Settings->Filament->Filament->Extrusion multiplier) set to? I'm assuming you've bumped it back based on calibration. You could just try reducing it 5% to see if it makes a difference.

Have you done a Linear Advance calibration for that filament? Setting it too low can result in a "dog bone" appearance at corners, caused by them over-extruding a bit.

One last thing to try would be setting Maximum volumetric speed to a lower setting, say 7mm^3/s, to ensure infill and external speeds stay closer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bulging corners

What I find very curious is that if you examine the upper 10 layers carefully, they are different, but consistently different in alternate layers, and the difference coincides with the infill pattern changing direction 90 degrees. One of my test prints showed the exact same phenomena.

But on this photo, it is also showing the terminus of each plane is being expanded (unclear from photo if all layers or only alternate layers are affected by this), which is consistent with k-factor / linear advance. Why the normal box isn't showing the issue and the custom box is, well, both need to be printed at the same time (same slice) to better diagnose what is happening).

RE: Bulging corners

@bobstro: I tried all your suggestions and the only thing that made a difference was moving the seam to the back. That removed almost all of the bulging.

I didn't try increasing the K-factor though. It's set to 30 now. The extrusion multiplier is 0.98. I tried 0.95, but it didn't change anything.

@tim-m30: Interesting find. I'm wondering if a different infill pattern will produce different results.

RE: Bulging corners

@bobstro: I tried all your suggestions and the only thing that made a difference was moving the seam to the back. That removed almost all of the bulging.

I didn't try increasing the K-factor though. It's set to 30 now. The extrusion multiplier is 0.98. I tried 0.95, but it didn't change anything.

If 0.95 didn't change anything, that means you may be able to go lower without ill effect. Search on "Prusa calibrate extrusion multiplier" for the Prusa article.

Do search on "Prusa Linear Advance calibration" . On mobile ATM, so can't provide a link, sorry. That will reduce but not eliminate the seam.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bulging corners

I have used the guides from Matt's Hub to calibrate both the extrusion multiplier and the K-factor. K30 was almost perfect according to that test. But I can try to increase it and see if the corners gets sharper.

RE: Bulging corners

I tried to increase the K-factor to 40, but it didn't help.