Boolean with Prusa Slicer to friction fit sized parts?

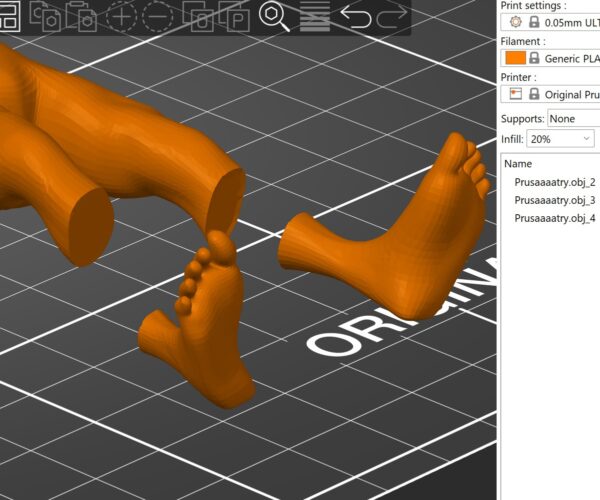

Greetings from Japan to you all good people. Im trying to make a figure as a birthday gift for a friends son.

I would like to join pants with the feet as a friction fit without glue etc. My printers tolerance is 0.21 mm.

There are many other parts to join eg the torso to the pants and the hands to the torso.

What do I need to do to make the hole- the boolean operation? If I resize the parts later will it work?

Is it possible in Prusa Slicer? If not what is the work around.

I have tried this with Mesh mixer months ago and I had problems with sizing the parts and though it was easy understanding the logic with mesh mixer I would rather do it in Prusa slicer where I can deal with the size I want for the parts.

Any tips would be appreciated. Thank you in advance.

F.Kennedy

RE: Boolean with Prusa Slicer to friction fit sized parts?

That's very difficult to do in PrusaSlicer. In theory it would be possible, but you would need to arrange the parts very precisely and be very careful when moving the different negative and positive cylinders you need to generate also you need to pay close attention to the hierarchy of the objects (starting with the torso and making everything else parts of it) so you can still move and scale stuff around. This is quite a job and would probably result in failure.

Even if you are proficient with meshmixer this would not be the tool of my choice, you have similar task to tackle (arrangement of the parts) there.

Easiest way to do that would be a CAD program of your choice (FreeCAD, Fusion360...) and it would be best if you had the model as a whole. Then you just can cut off the Parts you want to print separately and add the cylinders, holes and tolerance in place.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

Thank you for your comments, Robin. I see. The free Fusion360 program gives me headaches when dealing with meshes from other programs with the triangular faces etc. I was wondering if there is a way to use one object to make boolean cuts in another object in Prusa Slicer while also allowing resizing for tolerances. I hope that is a future slicer tool !

RE: Boolean with Prusa Slicer to friction fit sized parts?

Its quite easy to make holes in Prusa Slicer. Just use a negative space modifier. Shape it like a cylinder or a box or whatever shape you want if you load a shape in from an external program. Thats the easy part.

The almost impossible part is placing those modifiers so precisely on all the different parts that they line up correctly during assembly. That's the point Robin made that you don't seem to grasp. With a whole model that isn't yet cut up you can add the boolean cuts first for the 'posts' to rejoin them. Once that's done you then cut up the model so the post hole is also cut in half too. That way they will align perfectly. That is possible in PS already, its just not that easy to do and the model has to be in one piece.

Its much easier in cad software. The slicer is not the best place to do it.

RE: Boolean with Prusa Slicer to friction fit sized parts?

Thank you, Neophyl . If I can quote you *The almost impossible part is placing those modifiers so precisely on all the different parts that they line up correctly during assembly. That's the point Robin made that you don't seem to grasp* Yes the concept is a little bit difficult to get, but as both of you have recommended a CAD solution, I will try and search into that. There seems to be limited videos on how to though. Thanks.

RE:

What you try to do is pretty basic stuff in every CAD program. Import your model, cut where needed, add cylinders to one side, subtract from other side, add tolerance, export as multipart object, done.

The problem with being new to CAD is, no program does what you expect and it's confusing a.f. - I know, I've been there. My suggestion, if it's all the same to you, get a "free for personal use" license for Fusion360 and start with any beginner tutorial on YouTube to get to know the basic usage. This will not take more than a few hours, but that's what it takes. Fusion360 is comparatively easy to learn.

If you plan to work with figures/statues more often, Blender might be the weapon of choice...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Boolean with Prusa Slicer to friction fit sized parts?

Got you, Robin. I have a basic understanding of Fusion but working with imported meshes has always given me problems. I will try and go back to Fusion and see if I can . Wish it were possible in Prusa Slicer. Thank you.

RE: Boolean with Prusa Slicer to friction fit sized parts?

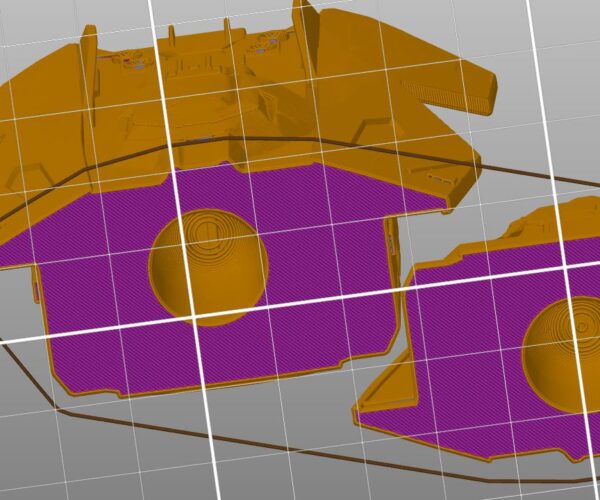

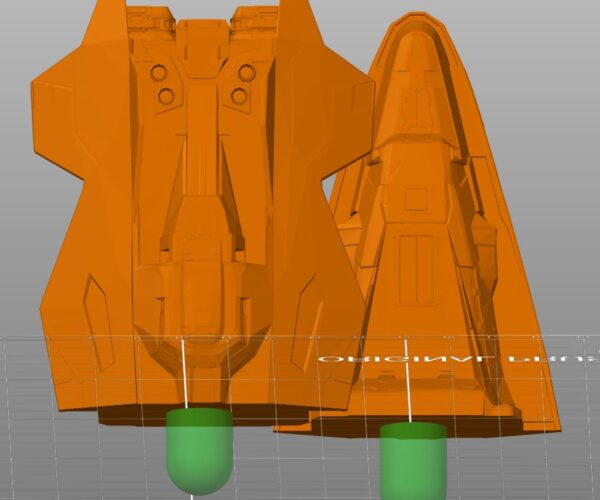

with the model in one piece, in Prusa Slicer, then I locate a new part in the area where I want a joiner, In this case I used a part with a rounded top, so I didn't need supports,

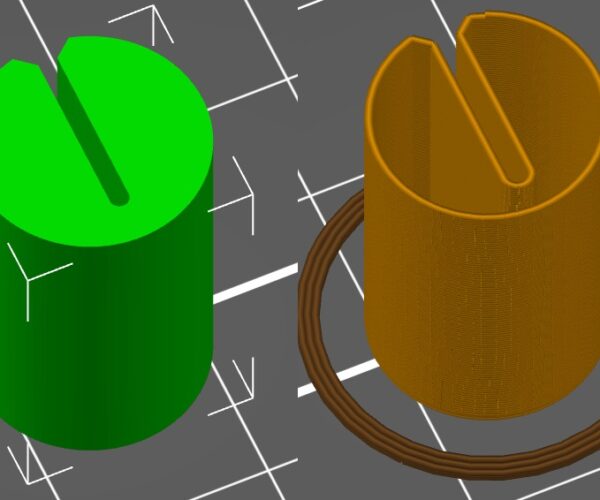

afyer locating the joiner hole part, I used the cut command to cut through the model and turn the bottom part upside down, and that gave me two parts with matching holes, then I made a split barrel to fit the holes, and printed it with no top or bottom layer and no infill. this could be inserted into the parts to line them up and being hollow it would deform to give a good friction fit Regards Joan

I

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Boolean with Prusa Slicer to friction fit sized parts?

Thanks Joan. I will research that possibility within the slicing software.

RE: Boolean with Prusa Slicer to friction fit sized parts?

The method Joan shows works great for models that you have in one part prior to cutting up. That's why I mentioned previously that doing it to a solid model is relatively easy, you place your holes when its one part and then when you cut the hole is in both parts and lines up perfectly.

Doing it to a model that is already in parts as you have pictured in your first post though is a whole world away in how easy it is to do. In that scenario you have to manually place parts and estimate their positions and hope the holes are perfectly placed. Something that is not easy in the slicer except with trivial shapes.

RE: Boolean with Prusa Slicer to friction fit sized parts?

Thank you, Neophyl. I will explore yours and Joans idea. Wish I knew how to make the split barrel as Joan mentioned but, so far I just went ahead and CAD software to cut the hole into the pants, then will reduce the leg in Prusaslicer to compensate for tolerance. Will try and print later tomorrow and see how it goes.

RE: Boolean with Prusa Slicer to friction fit sized parts?

If you scale down the leg to compensate for tolerance, the leg will - well - be scaled down, meaning no longer fit the rest of the model, you just need to scale down the bolt you generate to fit in the hole to be scaled. Or, as Joan does: use a hole in each side of the model and print fitting split barrels instead, no need to scale anything of the model... I attached a 3mf with a slit barrel (including slicer settings for perimeters) much like the one in Joan's picture, took 1 minute to generate in Fusion (Create cylinder, add sketch to to surface, draw rectangle, extrude to other side of cylinder, round 4 edges, export to slicer), for your scaling and printing pleasure.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Boolean with Prusa Slicer to friction fit sized parts?

Thank you Robin for the great reference file. Helped a lot. At least thanks to you all and your suggestions, I can see myself coming up with a solution in a couple of days.