Bizarre Warping w/ PolyMax PC?

Hello,

I am printing PolyMax PC on my enclosed Mk3S+ and getting this strange warping where the bottom of the print appears to be contracting and causing the print to bow upwards in the middle, which, to my experience, seems opposite one would expect (where the sides would bow upward due to the top layers contracting). My goal is to print the part completely flat.

Nozzle Temp: 260

Bed Temp: 115 (Nylock bed leveling was performed for this bed temp to an ensure the bed isn't causing the warp).

Enclosure Temp: 40-50C

Smooth Sheet w/Glue stick. Perfect adhesion through print. Warp only happens when I remove from bed.

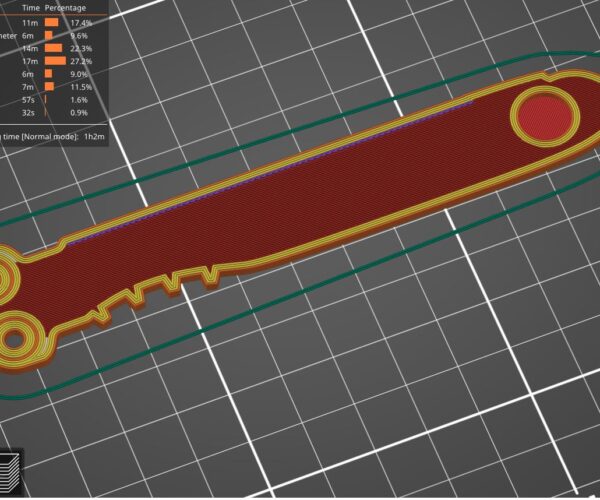

Infill: 99% Rectilinear (I recognize the high infill will contribute to warping, but I'm trying to make the part as strong and heavy as possible).

Perimeters: 4

Fan OFF

I've also tried nozzle temps between 260-270, bed temps between 105-115, and tried an infill line width of 0.9mm, but none of these changes appeared to reduce the warping.

Any help is much appreciated!

RE: Bizarre Warping w/ PolyMax PC?

Since the bed adhesion seems not to be the issue, you could try to leave the print on the bed after is completed and let it cool down slowly (maybe you can try decreasing manually the bed temperature, like in a span of some hours).

I'm not an expert. Ma parlo anche italiano 😉

RE:

Since the bed adhesion seems not to be the issue, you could try to leave the print on the bed after is completed and let it cool down slowly (maybe you can try decreasing manually the bed temperature, like in a span of some hours).

Thus far, I tried leaving the part on the bed for an hour at 115C immediately following the print, then letting it cool to room temp before pulling it off. Getting the same amount of warping.

I then tried letting the part cool down for an hour after printing, followed by reheating the bed to 115C for an hour, and then letting it cool to room temp before pulling the part off.

Neither of these solutions reduced the warping.

I am currently running a print with a reduced bed temp of 105C, programmed to cool for an hour after the print, then reheat to 100C for an hour, and then a controlled cooldown from 100C to 60C over the course of 40 minutes. I'll report back how it goes, but based on the above tests I'm not overly optimistic.

ALL ideas are welcome!

RE: Bizarre Warping w/ PolyMax PC?

A few months back there was already a discussion around that: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/printing-larger-parts-with-pc-blend-issues/#post-492301

I have eventually given up on using PC-blend for the sheets I wrote about in the above thread but the annealing did help quite a lot. Two flat, heat resistant objects (I used pizza stones) and a few kg of weight on top, two hours at 120degrees and the parts were flat.