yet another PLA Filament Not Sticking post

Aloha, forum!

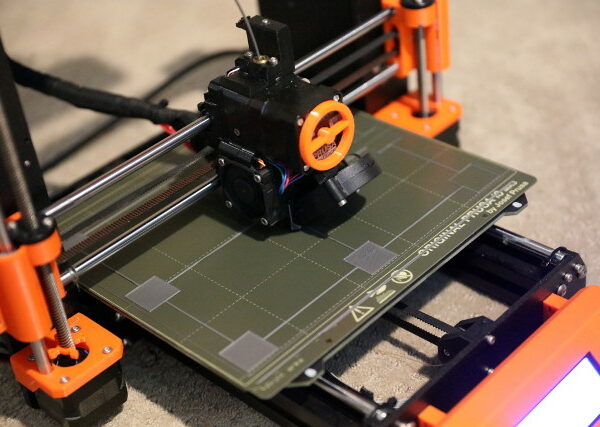

I’ve recently inherited an MK3S for my robotics class at our local charter school. I read the manuals, cleaned the unit and ran the calibrations, cleaned the sheet between builds with 90% alcohol, and it worked wonderfully fine for a week.

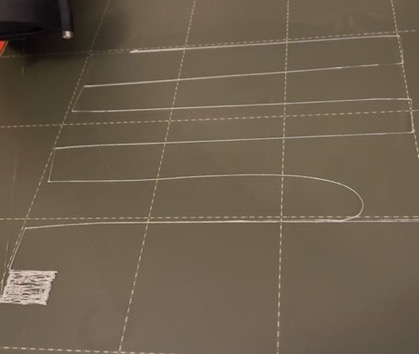

Then the PLA stopped sticking to the surface, and now the first layer calibration tests look horrible. (See pic below)

I’ve changed the build sheet (both textured and satin) and recalibrated, changed the nozzle and cleaned the extruder gears, tried different PLA filaments (some brand new), cleaned the sheets with soap and hot water (not acetone), and tried glue sticks. The results are still the same:

First layer calibration test has thin, spider web lines that don’t stick, and the final pattern (at 0.00 Z) is globby with gaps and blobs. If I adjust for more space, even just a little, the results are worse.

I’ve read many forum entries and of course the knowledge base for common printing problems, but to no avail. I’ve ordered some plate adhesive, but thought it worthwhile to ask the fine folk here.

Stats:

Total filament: 1406.2m

Total print time: 23d 05h 02m

Firmware: 3.10.1-4697

Best Answer by Thomas:

Glad to hear that at least all parts are now tightly screwed together. That usually helps 😀. From your description of what you're experiencing, I think it's now a matter of making sure the PINDA sensor is correctly placed, and running a successful first layer calibration. Here are a few tips to ensure the PINDA is at the right hight and the z-adjustment set correctly:

- The PINDA sensor detects the metal plate when it comes close. There's a red LED on the top of the sensor that switches off when the sensor senses the plate so you know that it works. When you do a z-axis calibration and the LED doesn't switch off when the nozzle is all the way down, you know that the PINDA sensor is too high. In my experience you should set the PINDA about 0.1-1.5 mm higher than the nozzle point. Certainly not much higher than that. I'll post a photo to give you some idea.

- Once you set your PINDA correctly, run a Z-axis calibration. When you adjust the PINDA sensor you must always run a z-axis calibration.

- Run a first layer calibration. Make sure you have the plate selected you actually do calibration for: Smooth or Textured. When you start with a new z-axis calibration it's safest to restart at 0.0 and not continue with an existing value.

- Adjust the z-axis so you get the filament to stick to the plate and that the filament has a slightly flattened shape. When the lines become a smear, you're too far (and risk damaging your plate). The z-axis adjustment value is supposed to be negative and at the end of the run should stay at the value you've set it.

- Examine the result: When you take it off, the printed line should come off without too much trouble and not break (that would mean it's too thin and nozzle is too low). The little printed square should be whole, with the edges intact. When you take the square off and bend it between your fingers, it shouldn't break but fold. If it breaks the filament hasn't merged together on the sides well enough and the nozzle is too high: adjust and run de first layer calibration again.

- Don't rush it. If you're not happy with the result, just run the first layer calibration again and continue adjusting starting with the value you set it on.

It's a little bit of work, but worth it. I really hope this works for you.

Good luck!

RE: yet another PLA Filament Not Sticking post

It looks to me like your Z calibration is too high.

I suggest that you first get the internal calibration close, dialing it down and in maybe 50 points at a time, and then go with any of various test prints to get things closer.

I prefer the 3x3 squares, as it prints quicker than those full-size prints and gives good feedback as to overall Z calibration, and any left/right and/or front/rear differences.

RE: yet another PLA Filament Not Sticking post

I agree with @jsw, classic z-offset too high.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: yet another PLA Filament Not Sticking post

I totally agree that your first layer calibration is off. Clearly too high. But I'm intrigued why that suddenly happened and in such a major way... ? The first layer calibration is really a calibration of the distance that the P.I.N.D.A. sensor is off the metal plate. This means that every time you adjust the PINDA sensor you always need to redo the first layer calibration for every metal sheet that you have. A high negative value for the z-axis adjustment of minus -1.8 or -2.0 means the sensor is placed low. Values closer to 0 mean the sensor is placed high. I recommend to place it so that your needed z-adjustment for the first layer is between -0.5 and -1.0.

Perhaps your PINDA sensor is loose? That could explain the sudden occurrence of your problem. Or perhaps when you were changing the nozzle and cleaning the system you moved it to a different position? Or, you accidentally reset the calibration to zero (I've done that...)? In any case, you'll need to do a new first layer calibration and keep adjusting the z-axis adjust until the filament catches the sheet, and until the lines are staring to be squished somewhat to a flattened tube shape (I hope that makes sense). The little square printed at the end of the first layer calibration should be fully closed, with consistent thickness, and no frilly edges. If not perfect, start again and continue adjusting where you left off.

Hope this helps a bit. Good luck!

RE: yet another PLA Filament Not Sticking post

Thanks for the quick tips! Yes the PINDA sensor screw was loose. Since that was loose, I checked all the other screws and yup, nearly all were loose! Gently tightened all the mountings, loosened and retentioned the belts, then ran the calibration wizard, and first layer calibration. Same results unfortunately, though the printer is SO much quieter now everything is tightened.

The problem seems to be that the nozzle is too high. I adjusted the PINDA position until the nozzle started pulling on the paper sheet (and I immediately turned printer off), then moved the PINDA down a quarter turn and re-tightned (single screw type). New ref point calibration didn't move paper, so I ran first layer cal again. Same results. nozzle seems too high, and no way to move it lower, Z offset set to 0.00. Scrubbed sheet again, just in case, and same results. I must be missing something in the calibration procedure. After any change, I re-run the wizard through to the first layer test.

Thomas mentioned I might have accidentally reset the calibration to zero - do you mean the Z adjustment in the first layer run? That one resets itself to zero after the wizard runs, and only goes negative (higher?)... is there another Z axis offset I might have reset not covered by the wizard? That could explain it, if it exists.

jaw mentioned a 3x3 test - I'm guessing that was the pattern printed in the image - can someone let me know where to download that test? I haven't found one like it on our SD card or online.

Once again, thank you all so much for your fast suggestions and help!

Mahalo,

dm

RE: yet another PLA Filament Not Sticking post

Glad to hear that at least all parts are now tightly screwed together. That usually helps 😀. From your description of what you're experiencing, I think it's now a matter of making sure the PINDA sensor is correctly placed, and running a successful first layer calibration. Here are a few tips to ensure the PINDA is at the right hight and the z-adjustment set correctly:

- The PINDA sensor detects the metal plate when it comes close. There's a red LED on the top of the sensor that switches off when the sensor senses the plate so you know that it works. When you do a z-axis calibration and the LED doesn't switch off when the nozzle is all the way down, you know that the PINDA sensor is too high. In my experience you should set the PINDA about 0.1-1.5 mm higher than the nozzle point. Certainly not much higher than that. I'll post a photo to give you some idea.

- Once you set your PINDA correctly, run a Z-axis calibration. When you adjust the PINDA sensor you must always run a z-axis calibration.

- Run a first layer calibration. Make sure you have the plate selected you actually do calibration for: Smooth or Textured. When you start with a new z-axis calibration it's safest to restart at 0.0 and not continue with an existing value.

- Adjust the z-axis so you get the filament to stick to the plate and that the filament has a slightly flattened shape. When the lines become a smear, you're too far (and risk damaging your plate). The z-axis adjustment value is supposed to be negative and at the end of the run should stay at the value you've set it.

- Examine the result: When you take it off, the printed line should come off without too much trouble and not break (that would mean it's too thin and nozzle is too low). The little printed square should be whole, with the edges intact. When you take the square off and bend it between your fingers, it shouldn't break but fold. If it breaks the filament hasn't merged together on the sides well enough and the nozzle is too high: adjust and run de first layer calibration again.

- Don't rush it. If you're not happy with the result, just run the first layer calibration again and continue adjusting starting with the value you set it on.

It's a little bit of work, but worth it. I really hope this works for you.

Good luck!

RE: yet another PLA Filament Not Sticking post

Snapdoodle the fundamental point is everyone is telling you to adjust the z offset, that is correct you need to - massively. The missing bit of information is that its supposed to go NEGATIVE. Negative values move the nozzle closer to the bed. So the larger the negative value the closer the nozzle will be. I saw from your post you assumed it to be a positive value.

RE: yet another PLA Filament Not Sticking post

Thank you for your elegantly worded suggestions, Thomas!

Using your and jsw's suggestions (and avoiding the wizard), I was able to tweak the PINDA to where I could get the nozzle just right. Thank you, jws, and Bob for all the positive feedback and suggestions.

RE: yet another PLA Filament Not Sticking post

Yes, Neophyl, I understood that and tried to state that I knew it. Since I couldn't move the nozzel downward, positive, I knew something else was wrong and was asking for help. Please do not reply.