Y calibration constantly lost

I've tried everything I can think of at this point, but no matter what I do the Y calibration (the heat bed) gets reset every time a new action is about to begin. I've reset factory settings, reflashed current firmware, run XYZ calibration 30 times...nothing works!

Even when I do a first layer calibration it likes to simply start from where ever the Y currently is. Meaning it could start all the way back at the heat bed, then rumble because it is hitting the edge over and over. The only way to solve this is to manually push the heat bed all the way back and hope that the next print or first layer calibration will fix it.

For further context, I can get the first layer calibration to complete successfully as long as I make sure the Y axis (heat bed) starts all the way back before I begin.

What sensor detects the position of the heat bed or Y axis?

RE: Y calibration constantly lost

The 'end stop' positions on all the axis are determined by the stepper driver reading an increase of current when it encounters an obstacle. Its the same thing it uses to detect collisions. Symptoms like you describe are usually caused by bearing and axis travel that are not smooth. Friction, sticky spots, bad bearings that don't have sufficient lubrication etc cause the mainboard to think its got to home etc.

Check that the bed moves freely. Best way to do that is to remove the y axis belt and move it lightly by hand to see if theres any area that isn't silky smooth. You can also tilt it and see if it slides but I find feel is better as you can detect the slightest bit of friction.

RE: Y calibration constantly lost

OK, I just took the belt off, and you are right...it was stiff. I lubed it up and it got better...not great. I am trying again. If this works I may try to 3d print those PLA bearings and replace the ones on there. Clearly they suck.

RE: Y calibration constantly lost

When you take them off be sure to properly lubricate the inside of the bearings. Its the one missing part of Prusa's build instructions. They say that they come prelubricated but ask anyone who deals with bearings they come with packing lubrication mainly designed to prevent rust. Get some good bearing grease in there and save yourself premature maintenance again.

RE: Y calibration constantly lost

@neophyl

What exactly am I trying to lubricate? Not the bearing's ability to spin right? Just the contact with the metal rod correct?

If that is the case, what bearing grease do you recommend?

RE: Y calibration constantly lost

@neophyl

That fixed the problem. Thank you for letting me know! Now I simply need to figure out how to properly lube them and what to use.

RE: Y calibration constantly lost

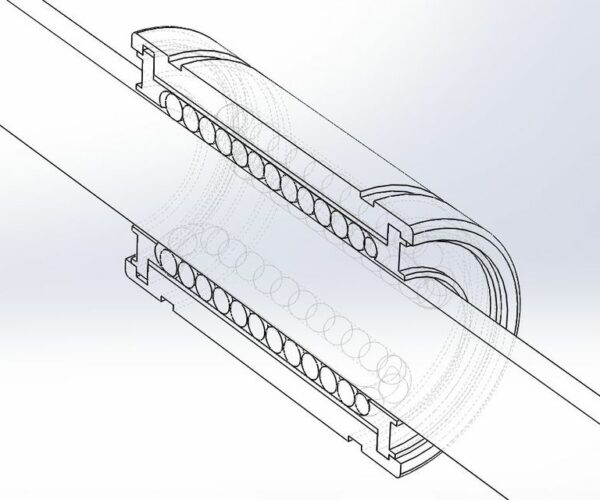

Inside the bearing are LOTS of tiny steel ball bearings. These are what is in contact with the steel rods. Whenever you remove a bearing be very careful putting it back on as if its not square the rod can force the ball bearings out and then your bearing is ruined.

There are as many opinions as to the 'best' lubricant but do a search for bearing superlube. There's quite a few videos on youtube too showing what needs to be done and there are various nozzles on thingiverse you can print, that attach to the superlube tubes to make the job less messy and much easier. Once the grease is inside the bearing and its on the rod the black seals help to keep the grease in and the dust out.

Also be sure to orientate the bearings following the Prusa Build instructions for your printer so that the balls inside line up for maximum support on the rod.

RE: Y calibration constantly lost

@neophyl

No kidding? I guess I thought that the bearings were standard ring bearings and that the literal metal of the inner ring was sliding up and down the rod.

This makes a ton more sense, but of course now I need to understand the actual bearing design. Are you suggesting that unlike a standard double ring bearing, the rod is actually responsible for holding the balls in place? So if I pull the rod out of the bearing the balls would scatter all over?

Thanks for the info on this. I need like an exploded view of the printer parts.

RE: Y calibration constantly lost

No if you remove the rod the ball bearings won’t just fall out. They do run in a race. However it is possible to push them out of the race by incorrectly inserting the rod. I know this for a fact as when my friend built his mk3s he did so on the z axis bearings by trying to fit his built x axis on in one go. It was fun collecting tiny balls and getting them to go back in with tweezers , not 😀

RE: Y calibration constantly lost

@neophyl

Oh, so is it the metal race that makes contact with the rod? If so, why do they even use bearings? Why not some kind of polished steel or plastic? Seems weird to me.

RE: Y calibration constantly lost

No a race is the 'track' that metal ball bearings move along inside the bearing housing. The steel balls are the contacts points between the rod and the bearing housing. That's why they need the proper lubrication.

Maybe this will help you visualise it

it

There are many different types of bearings, from many manufacturers. Number of races vary, design of races etc. Some bearings do work like you describe with self lubricating surfaces being in contact (look up IGUS bearings as an example).

RE: Y calibration constantly lost

Print pla bearing will not work.

After you have the printer working again, you need to do maintenance(every months or weeks), clean rods, and put thin oil on the rods, search forum for what kind of oil you need to use.(oil with P.F.T.E inside).

Also check al parts if something is loose, push extruder if bolt are loose.

Then check all bolts if they are loose, with a small mirror you can look at the backside and check the bolts.

RE: Y calibration constantly lost

@neophyl

That is exactly what I wanted to see! I've never seen a bearing like that. Really interesting.

RE: Y calibration constantly lost

Print pla bearing will not work.

After you have the printer working again, you need to do maintenance(every months or weeks), clean rods, and put thin oil on the rods, search forum for what kind of oil you need to use.(oil with P.F.T.E inside).

Also check al parts if something is loose, push extruder if bolt are loose.

Then check all bolts if they are loose, with a small mirror you can look at the backside and check the bolts.

For an emergency, these have been tested to work by numerous people. I printed an entire extruder set using them on my X and Y axis. PLA lubricates better while PETG has better thermal resistance. I used PETG.

https://www.prusaprinters.org/prints/24017-emergency-spare-bearings

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1