Uneven top surface on prints

Hi!

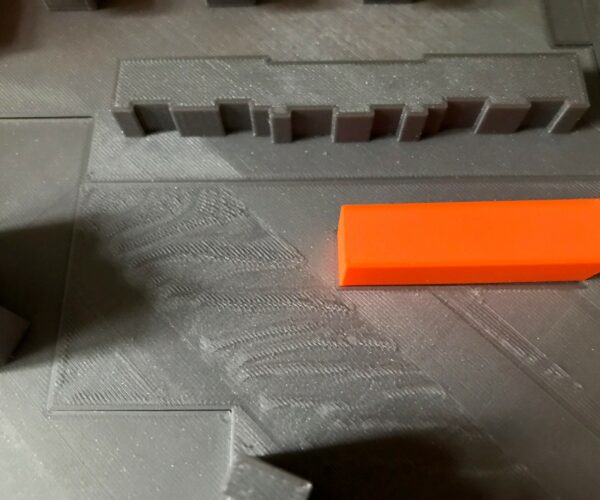

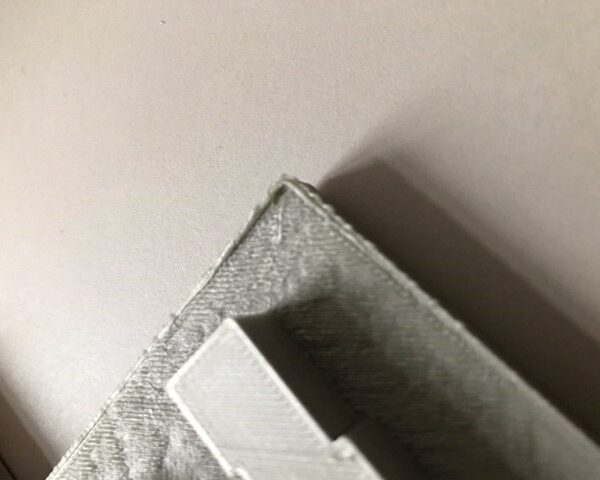

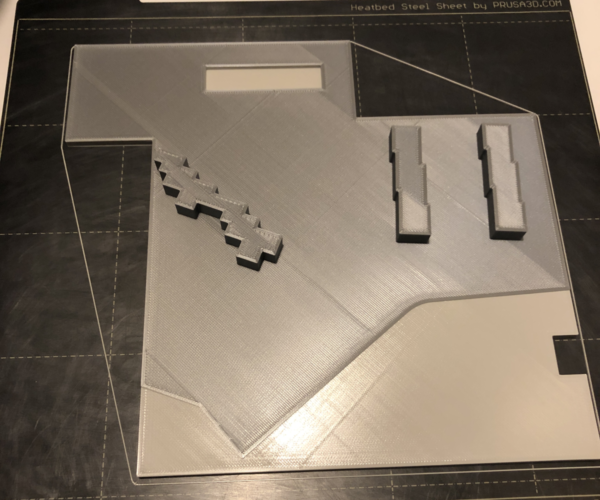

We own a MK3S. Since a few days it prints a quite uneven surface on the top layer of the print. The strange thing is not all of the top surface is bad. Sometimes 70%-80% of the print are fine and just a small area ist uneven/wavy. Most of the time the uneven area is located on the left back side (standing in front of the printer) of the print. We usually print acrhitectural models. Therefore the areas with flat surfaces are usually quite big.

Can anyone help with this?

Thank You!

RE: Uneven top surface on prints

Are you using 7x7 mesh bed levelling?

are you using Prusa Slicer?

have you tried the new alpha release version of Prusa slicer (2.3.0 Alpha4?)

it has monotonous infill and ironing, both of which may help you

have you tried a different top infill, say hilbert curve?

Have you checked the filament diameter matches what is stated in the slicer?

Are you changing the extrusion multiplier during slicing?

It looks like the nozzle is making trough's in the surface of the print, have you tried reducing the flow rate a little, normal flowrate in Prusa Slicer, is 95% for layer heights above 0.07mm try 90% flow rate (Slight under extrusion is easier to manage than over extrusion).

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Uneven top surface on prints

Thank you Joan!

Will try your suggestions. Few answers in red below.

Thanks!

Jasko a5

@joantabb

Are you using 7x7 mesh bed levelling? yes. calibration also said the bed is straight (it was slightly unlevelled before. i redid the installation and now its completly levelled)

are you using Prusa Slicer? yes

have you tried the new alpha release version of Prusa slicer (2.3.0 Alpha4?) will try it, thank you

it has monotonous infill and ironing, both of which may help you

have you tried a different top infill, say hilbert curve? will try it, thank you

Have you checked the filament diameter matches what is stated in the slicer? will check it

Are you changing the extrusion multiplier during slicing? no

It looks like the nozzle is making trough's in the surface of the print, have you tried reducing the flow rate a little, normal flowrate in Prusa Slicer, is 95% for layer heights above 0.07mm try 90% flow rate (Slight under extrusion is easier to manage than over extrusion). ok thanks

RE: Uneven top surface on prints

how old is the nozzle?

have you been using abrasive filaments?

could the nozzle be worn?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Uneven top surface on prints

The nozzle is almost new. It printed maybe 1 kg of filament so far. We don´t print that much. Also we have only used pure PLA so far.

RE: Uneven top surface on prints

Large flat top areas can be a problem with pillowing when the infill % is low. It could be that on the model but its hard to tell.

If the model isn't proprietary would you save the project that has that issue (File>Save as) which will output a .3mf file. Take the 3mf file, zip it into an archive and attach it here.

The 3mf contains not only the model but all the settings of the profiles you are slicing with. Its the best way to debug these things as it allows us to slice with the same settings you are using and look at the preview layer by layer.

RE: Uneven top surface on prints

@neophyl

Hi!

Thanks for your reply. Please find the .3mf file attached.

RE: Uneven top surface on prints

Looking at that I would change infill to 15% to possibly 20% rectilinear to get enough support for the large top layers. 15% is probably enough though. Rectilinear as the infill is quicker to print and doesn't bump over the lines as much as the grid pattern you have selected.

If you want to gain back the extra time taken using the greater infill % you could also try a print with Print Settings>Infill>Reducing Print Time>Combine infill every set to 2 which will make your infill thicker and print it every 2 layers.

RE: Uneven top surface on prints

@neophyl

Thanks for the tip. Will try it and report afterwards.

RE: Uneven top surface on prints

@neophyl

Hi!

So i resliced the model following your advises and let it print overnight. Unfortunately no change whatsoever. Next step is going to be to try out the alpha release of the slicer.

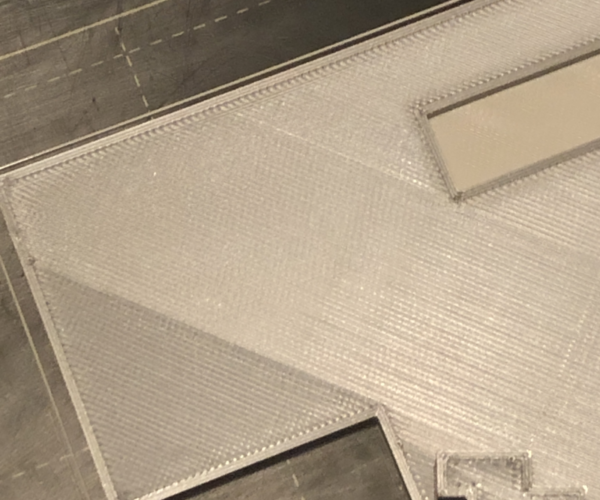

If one looks on the finished model, it´s quite strange that some surface areas are smooth and some uneven. Why does it print smooth in some areas, but doesnt in others?

RE: Uneven top surface on prints

Here is the 3mf file with the new settings.

RE: Uneven top surface on prints

That's a very interesting question, why does some of it print flat and other section pill. I think I'm going to cut the bottom off by 6mm to make it a bit quicker to print and have a go at printing it with my normal settings. I'll keep the infill the same though. There's still enough infill before the top layers that the height shouldn't make any difference.

RE: Uneven top surface on prints

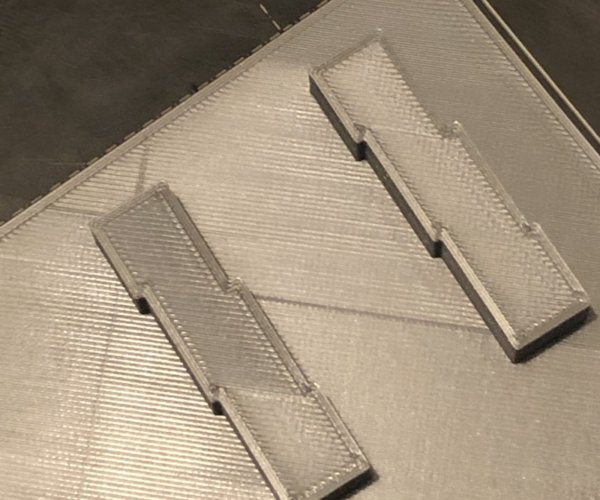

Ok I had a go at printing a slightly modified version of your project last night.

Firstly I sliced 6mm from the bottom using the cut function, then I trimmed off the tops of the buildings. This was mainly to speed up printing a reduce filament used. As we are only concerned with the large flat areas on top of the infill anyway this shouldn't make any difference to those features.

I mainly used your Print profile, same infill type and % and same number of bottom and top layers etc. I did use 3 perimeters as thats just normal for me. I did change the filament and printer profiles to match the filament I was using and my printer though.

If you look at them you will see there are changes beyond the normal. The filament profile is set to print PLA at 220, however the Spectrum filament I used has a print range up to 220 and my printer is fitted with a Nozzle X. which is a steel nozzle so temps need to be bumped 5-10 degrees anyway. SO its the equivalent of printing the filament at 210. I also generally use less cooling by default with it increasing for bridges. The filament is also set to a diameter of 1.755 as that is the actual measured average for my filament. This is all part of basic filament tuning.

My Printer also has a geared extruder modification (it was originally a normal MK3 non S variety). This means I have different retraction speed settings but I also don't think that's a factor in your printing issue.

I have attached the project file I used to print with.

As you can see from the picture the part printed fine. There is absolutely no indication of the same problems you are having. It has the merging lines issue that 2.2.0 has with rectilinear. Normally I'd be using the alpha releases with the new Monotonic infill type which prints all in the same direction to fix that problem but I wanted to use the same slicer version you are using to take that out of the equation.

So I don't think its related to any of the settings in the Print profile.

I could be related to your filament. If your filament is slightly oversize like the spectrum ones then with a default diameter of 1.75 it will actually be over extruding slightly. Its maybe possible that could be contributing to the issue by building up too much filament on those layers over time. I would suggest measuring your actual filament diameter average at several points with a set of callipers and entering the value into your filament settings. This gives the slicer a more accurate picture to work from when calculating how much plastic to push out.

Your printer profile looks standard so I don't think that's an issue either.

On to the pics of the print. (As I was using end of rolls I had to do a filament change in the middle but that didn't cause any issues either)

RE: Uneven top surface on prints

@neophyl

Hi Neophyl!

Thanks a lot for your effort and help. Guess i will have to start troubleshooting the hardware. The used filament was original Prusa, but i will check it anyway.

Thanks a lot.