Stringing prints that used to work

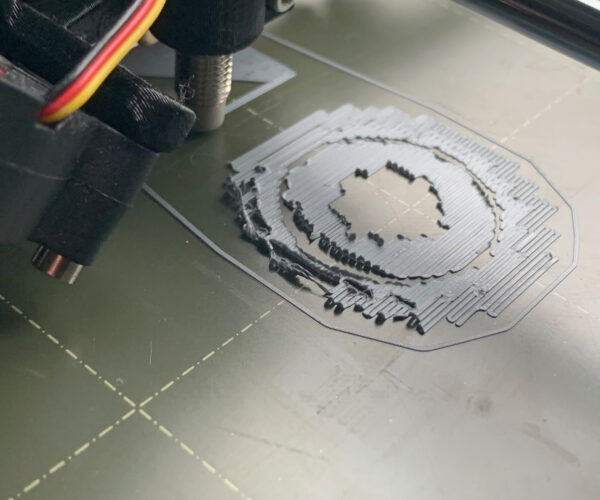

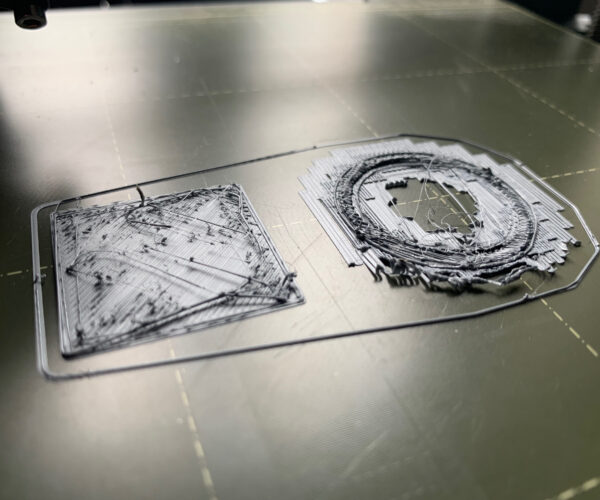

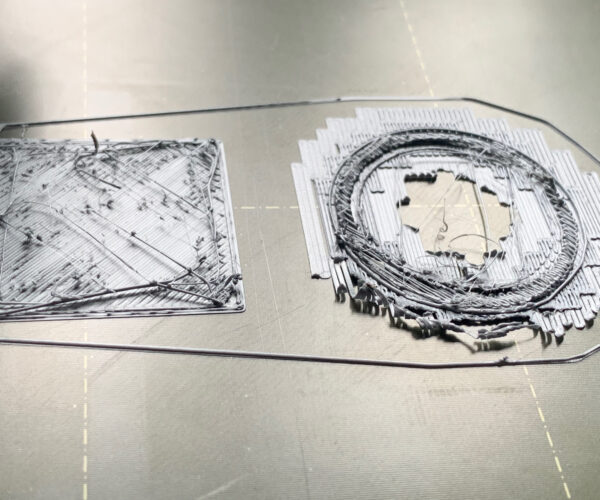

Firstly, I hope this is the correct location, apologies if it isn't, this is my first post here. Some background, I have a Prusa MK3 and it had been working perfectly printing PLA prints. I decided to try ABS which for some reason just clogged the nozzle. Unclogging it decided to abandon the ABS prints and go back to PLA, except now it just does this

I have cleaned and wiggled some bits, but I don't really know what to do next, I'm guessing given it used to work and nothing has changed except me unclogging it, I have damaged the nozzle, but given the upper parts print I question this.

Thankful for any help, and again, if this is the wrong space

RE: Stringing prints that used to work

You need to do a cold pull and clean the nozzle out. You might also benefit from purging the ABS from printer. You probably have some residual causing a partial clog.

--------------------

Chuck H

3D Printer Review Blog

RE: Stringing prints that used to work

You need to do a cold pull and clean the nozzle out. You might also benefit from purging the ABS from printer. You probably have some residual causing a partial clog.

Thanks so much for answering,

So... probably another stupid question, what is a cold pull, or is that something I can just google. Additionally, how does one purge? I've forced through from above and cleaned from below, are we talking a more thorough deconstruction =.

RE: Stringing prints that used to work

There are a number of videos on YouTube. I am on the road so I cannot point you to the best.

https://www.youtube.com/results?search_query=cold+pull+Mk3S

To purge, I load a purging filament such as eSun. There are several manufactures and you can just pick the best price. After the cold pull and when I change filament types such as ABS to PLA or Vice Versa, I will do a purge. You load this filament. I use the temperature of the highest of the two filaments I plan to change to or from. I allow it to melt in the nozzle. After 2-3 minutes of melting, I run a purge filament from the menu or simple advance the filament. I allow it to sit 2-3 minutes and repeat the purge.

If neither works, I often replace the nozzle and use a heat gun to un clog it.

I hope this helps.

--------------------

Chuck H

3D Printer Review Blog

RE: Stringing prints that used to work

Firstly, I hope this is the correct location, apologies if it isn't, this is my first post here. Some background, I have a Prusa MK3 and it had been working perfectly printing PLA prints. I decided to try ABS which for some reason just clogged the nozzle. Unclogging it decided to abandon the ABS prints and go back to PLA

Chuck's given the basics, but just a bit of explanation. I went through a similar experience starting out. The important thing to remember is that anytime you go from a higher-temperature filament (e.g., ABS) to a lower-temperature filament (e.g., PLA), there's a possibility that a bit of filament or residue can be left behind in your hotend and nozzle. The lower printing temperatures may be insufficient to melt this residue out.

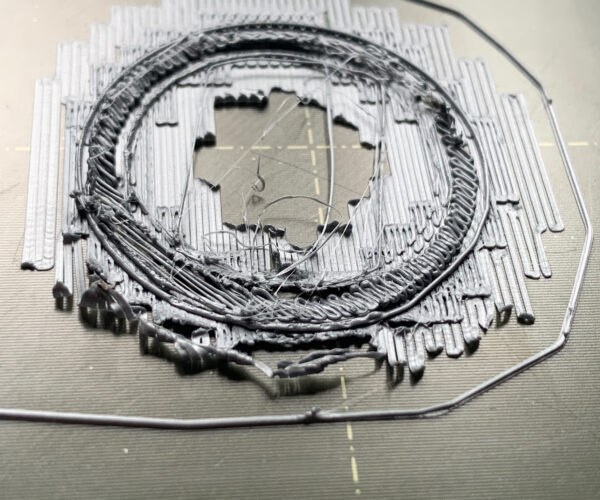

A cold pull works by shoving some flexy material into the hotend and nozzle, heating it up to temperatures above the higher-temp (e.g., 265C to clear PETG that prints at 230C) to melt everything, then leaving the molten material in the hotend and nozzle so it will trap the crud. Once cool, you start heating the nozzle and pull the filament out the top of the hotend/extruder. This is done so that any crud bigger than the nozzle opening will be lifted out. You want to start pulling at a temperature well below the melt temperature so the pulled filament will be soft but not snap. With any luck, you'll get a good impression of the inside of the hotend and nozzle as shown here:

If there's a lot of crud visible, repeat the process until results look clear.

I'm fond of eSun cleaning filament since it melts at a wide range of temperatures. I can use it to melt high-temp stuff at 265C, but know that if any is trapped, it will still melt out with PLA at 200C. It's also flexy. With a bit of practice, you can use any filament in a pinch. White is recommended.

I've got some detailed notes here that might be helpful.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…