RE: PRUSA edition heat break easily jam/clog with PLA

Hi Istvan, what is the ambient temperature where you are?

Here is it 19C to 20C... that may have a factor in the issue

,have you tried a temperature tower?

there are some examples on Prusa Printers web page

this particular filament seems comfortable in my mk3S with the prusa style heatbreak. at around 195 Centigrade!

this is Filamentive rPLA that is of unknown age, it was gifted to me by a stranger on a recycling site. who didn't know what it was, but thought a complete roll of something was too good to dump... since then, I have left it in the open with no special storage actions taken

I guess it's amazing that it still works... 🙂

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

Hi Joan,

Here in Hungary room temperature is more like 23-25C this time of the year which can easily move up to 27-30C in the summer without A/C.

I've only printed temperature towers for my PETG filaments, and not yet for PLA. I can give it a go later.

My filament storing method could definitely have some improvements. At the moment I'm only putting my filament drums in some plastic bags together with the original silica gel, and folding over the opening of the bag before putting it back to the cardboard box. It's definitely not airtight.

I hope I can get some Ikea Samla containers for my filaments once the pandemic situation gets handled.

RE: PRUSA edition heat break easily jam/clog with PLA

the temperature tower may give surprising results, give it a go...

did your silver flaiment always give problems or did it work ok at first? if the filament deteriorated with age you may be getting water absotbtion,

do you have an electric oven that can go down to about 60C or a filament drier? that may help you re constitute the filament?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

Hi Istvan, I already mentioned it in a different topic where I described my fight with the extruder constantly clogged with PLA. I tried a lot of different things mentioned here (temperature, retraction, heatbreak change) but for me, the major improvement came when I mounted a dust filter with a piece of sponge with a drop of oil (I used rapeseed oil). At first, the dust filter with oil was the last thing I wanted to install as I did not believe it has no adverse effects on printing process and print physical properties, but nothing else really worked for me so I tried it and was then able to successfully finish a 50 hour print.

Still, I hope I will be able to improve the system and get rid of the filter some day.

Regards, Ondrej

RE: PRUSA edition heat break easily jam/clog with PLA

Hi there,

just a quick note. I am not that much convinced of the "original/standard" Heatbreak anymore. Its not bad, however I do still have cloggings in the chamber. Please note: in the chamber. It seems ambient whatsoever plays an important role.

My definitive guide to clogging:

- get white PLA (this is the worst, silver is next)

- have ambient 30°C plus

- print something with lots of retracts (like a Voroni egg 🙂 )

My take (I like to print in a chamber): Avoid PLA.

I only need PLA for stuff with lots overhang/bridging. I try to get around it.

cheers

RE: PRUSA edition heat break easily jam/clog with PLA

In the past two days I've printed with PETG for 20+ hours without any issues.

Today I've decided to give this M3 screw holder a try because it's simple, and shouldn't have too much retractions. I've given the reduced 195C extruder temperature a try (0.2mm and used 70% speed because the printer was running in the same room where I had lot of meeting calls and the Z axis still has some whine at 100% even in silent mode).

It clogged a little bit after 2 hours, this is how far it got. You can see the thicker end of the filament after unloading.

RE: PRUSA edition heat break easily jam/clog with PLA

I didn't read all of the pages of this post, however, I have had this exact problem recently with my I3 MK3s. I will try the solutions mentioned earlier in the thread. The first time I had this issue was when I started printing with Prusament Vanilla White. I've been printing with Hatchbox white for over a year with no problems(but good luck getting that right now...) Hope it helps!

RE: PRUSA edition heat break easily jam/clog with PLA

I have since replaced the extruder by a Copperhead extruder & heatbreak and had no clogs since 🙂

RE: PRUSA edition heat break easily jam/clog with PLA

Hi,

I have for the same issue as mentionned in this post.

I want to replace the heat break with a standard e3d on my mk3s but i don't understand if it's necessary to replace the heatsink or not.

Because if I compare pictures on e3d shop the prusa version seems to be wider than the standard one

someone who already change it on his mk3s prusa Can Help me ?

RE: PRUSA edition heat break easily jam/clog with PLA

You don't need to change the heater block.

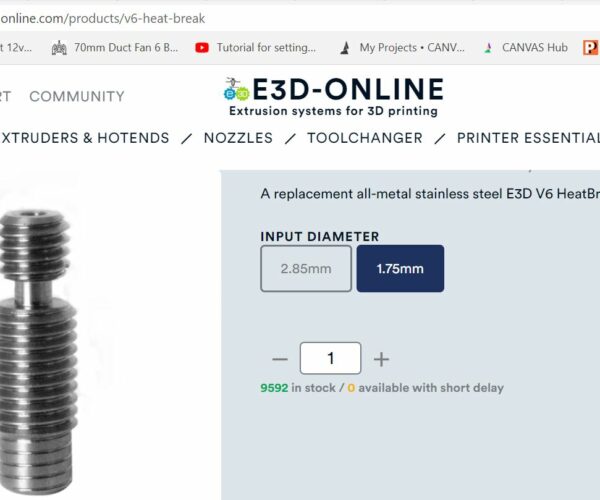

this is the heatbreak you need,

Make sure you select the standard 1.75mm version (NOT the Prusa specific heatbreak!)

you might be wise getting a spare heater and thermistor, just in case you have problems... get the Prusa specific, heater and thermistor...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

hi @joantabb

thanks for your answer. Then to summary for me and for other people who find this topic. the shopping list must be :

MANDATORY:

standart heatbreak 1.75mm

https://e3d-online.com/products/v6-heat-break

Thermal Compound Paste

https://e3d-online.com/products/thermal-compound-paste

OPTIONAL JUST IN CASE:

Prusa Specific Thermistor

https://e3d-online.com/products/prusa-specific-thermistor-mk2-mk3

Heater 24V 40W

https://e3d-online.com/products/standard-heater-cartridge

RE: PRUSA edition heat break easily jam/clog with PLA

I would like to add, that since the last time I've ordered some eSun PLA+ (peak green) filament, and I had three successful prints in a row without any issues or clogging. Using the PrusaSlicer default PLA preset, printing with 70% speed dialed on the printer. One of the prints was 11+ hours in length (Adalinda). The third had many small retractions (Cute Mini Octopus from Thingiverse). It worth giving it a try before modifying the printer. In my case it seems the Plasty Mladec filament coming with the printer was the issue (either bad quality, or becoming old/bad).

RE: PRUSA edition heat break easily jam/clog with PLA

maybe the PLA is the issue in your case. in mine I've just bought 13 spools of prusament PLA from prusa shop and same result with two differents spool, jet black and pearl mouse even if with the jet black it's worst. With jet black the print failed very quickly.

If I want to have a finish print I need to disabed retraction but it's not a solution.

I'm very very frustrated because I've spent 300€ in prusament to be sure to have an excellent filament and no issues with it...not the case...

RE: PRUSA edition heat break easily jam/clog with PLA

Just to add a data point: I've had no problems since installing an E3D Titanium heatbreak. I've also ordered a bimetal heatbreak for testing. This is a very easy swap, especially if you've got to tear down the hotend for other maintenance. Just be sure to use thermal paste at the TOP of the heatbreak where it screws into the heat sink fins and NOT at the BOTTOM where it screws into the heater block. Consider also installing a nickel-plated copper heating block while you've got it all torn apart. This is not required, but improves heating and flow.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PRUSA edition heat break easily jam/clog with PLA

Also as a data point...

I also replaced my damaged heatbreak in February with the E3D Titanium and it has worked well for the past 600 print hours. Prior to the change out I had filament oozing issues past the thread on the top side of the heater block which built up enough to invalidate the heatbreak, when I pulled it apart I found that the thread in the heatblock was damaged and the Nozzle could not seat properly against the heatbreak allowing the molten filament to slip up the thread. I have read a lot of posts re the special prusa design of the stock heatbreak (which is different to the base E3D versions) but am of the view that this mod was a fix for the 1st series of MMU rather than the refined MMU2S... of course my thinking will change if I do strike failures. It would be nice if Prusa could be more definitive of their design thinking on this.

With the E3D titanium break I am find that about a 0.6mm retraction works for PLA (I use ESun filaments) and increase it to 0.8mm for PETG. Other than filament temperature and 1st layer speed settings I rarely have need to tweak the standard Prusa Slicer settings.

I have changed the nozzle size a couple of times (0.25mm ) with no issues.

What I have observed is that if you don't have a silicon sock on the heater block when the print fan kicks in (even at low % rpm) there is a real drop in heater block measured temp (up to 10C for 30 secs) until it re compensates and may raise the risk of extruder grinding and eventual filament handling faults.

I also do have a MMU2S but other than doing multiple layer colour changes (automatic MMU change), I have not since the heatbreak swap out done an intensive MMU Colour print but otherwise the "simple" layer changes did not present any heatbreak issue. The only MMU problems have been the typical MMU filament load/retraction issues.

I have not observed any grinding build up in the the extruder hob either.

cheers

BC

RE: PRUSA edition heat break easily jam/clog with PLA

This is a glorious upgrade. I put one of these in over a year ago and have had very few issues aside from the melting pinda holder on the R4 extruder (part of the mkês upgrade)

RE: PRUSA edition heat break easily jam/clog with PLA

Ive just been getting this issue as well, been printing great for a year and now suddenly this. Had to replace the PTFE tube cos the feeder gears ground up the PLA and it caused a jam in the top. Print will go for a while then just stop extruding, sometimes with clicking. unloading reveals a blob on the end, cutting it off and reloading it sees it working again.

I just spoke to someone on the Prusa chat and they told me the issue with the 2.2mm heat break was fixed for the 3s and thats not whats causing it, but Im having trouble believing them with what ive read and experienced. I cant print anything at the moment as it just fails and thats with a simple flat piece with no infil. The only thing that has changed recently is the room temp, being in the UK I have no air con and its got up to 29c in the room its in today.

I tried putting my crappy floor standing air con unit on in there yesterday, but the windows are not designed in a way that I can pipe out and seal the room, and it managed a terrible 3c drop in an hour and a half in a small bedroom with the door shut.

Ive got some new nozzles coming tomorrow on the offchance its that but I dont think it is because it will go again once I trim off the blob from the end and reload it.

Does the MK3S have the 2.2mm heat break in it or no? cos Im at a loss right now.

RE: PRUSA edition heat break easily jam/clog with PLA

The stretched bit of fillament is what I managed to unjam from the heat break after taking it appart and heating it with an embossing heat gun till it came out.

RE: PRUSA edition heat break easily jam/clog with PLA

I've just changed by new one :

- Ptfe tube from prusa

- Nozzle e3d V6 0.4

- heatbreak e3d (titan)

And then first try with prusament jet black pla, default settings in prusa slicer in 0.1 on a benchy, After 1 hour bam cliking several Time and extruder motor seem to be hot for me and i touched the heatsink and it is cold. Then i pause the print unload pla (pla seems to be ok), cut it, reload and resume the print. After 2 more hours print finish.

Then replace the heatbreak dors not solve my issue :'(

I will try with a other New spool of black prusament pla tomorrow.

Is there someone have an Idea if the issue Can be the extruder motor or his temperature Can be the issue ?

When pla jam i should increase or descrease the nozzle température ?

Thanks for your help

RE: PRUSA edition heat break easily jam/clog with PLA

Hi All,

I had this exsact same problem on my MK3s.

I got it in kit form and assemlbled.

Jamming PLA, PETG, Retractions 1.2mm @ 45mmps

When I put in the E3d original heatbreak I noticed that there was no thermal compound between the original Prusa Heatbreak and heat sink and the heat sink its self was sitting much closer to the heater block.

The heatsink now sits high and proud and I have not had a single jam since swapping the heat break. PLA, PETG, Nylon Retractions Still live around 1.2mm @ 35-45 and this seems to create very little strining with my PETG.

Hope that helps someone,