RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

Dis you try replacing the noctua fan with a more powerful one ? There are some case where it solved people jam

RE: PRUSA edition heat break easily jam/clog with PLA

I have not tried a more powerful cooling fan.

The cold section is near ambient temperature to the touch so I don't think that is the problem here. I solved my problem by making sure that the PTFE tube ID in the cold section above the heat break is less than the PTEG ID in all other sections through the MMU2. This insures the tip created by the unload retract cycles is smaller than the remainder tube ID's and therefore will not get stuck on future loads..

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

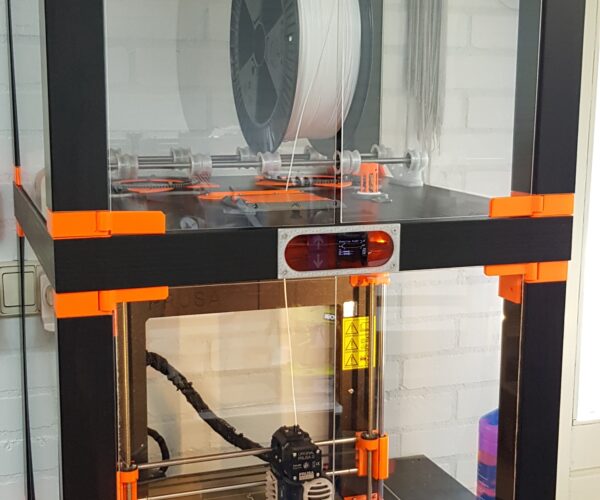

My printer is in an enclosure. See: https://www.thingiverse.com/thing:2396990

Ambient temp can raise into the low 40C. I found that the tip on the filament following retraction is approximately the size of the Inside Diameter (ID) of the short PTFE tube that lines the cold portion of the E3D hot end. That being the case I found a PTFE tube of 1.9mm forms a tip of 1.9mm. If the remaining PTFE tubes have a ID of 2.0mm, then no clogs occur on filament load.

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

Hi Wouter...

Ambient rarely gets that high in the Uk...

I usually print at 22 ambient without enclosure,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

@james-m15 : Thanks for your explenation. But I guess your talking about filament getting jammed during unloading or loading with a MMU, right? Good tip for when I will get an MMU.

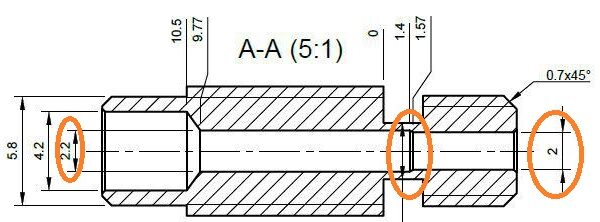

But I was talking about PLA Jamming up in the 2.2mm to 2mm narrowing in the heatbreak between 30 and 90 minutes into a (cold start) print (what only seems to happen with ambient temperatures above 31C.) If you can print PLA just fine with temperatures just below 40C then I'm kinda curious to find out what is different in your setting compare to others having this problem.

What I just realize now... you are saying you have only a 2mm ID PTFE tube? How do ya get a 2.2mm plug through those? Formed by this problem discussed here? I will link the pick again to be sure I'm not missing something...

The PFTE tube should only enter until the 4.2mm OD hole on the left. If that is fitted with only a 2mm ID PFTE tube, you would most likely never be able to pull out the jams (through the PFTE tube) that is discussed here.

2.2mm diameter plugs pulled out from PLA jams during summer days or closed enclosure.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

During summer all my PLA prints look like this :

The higher once in the back are started in the evening or night, but would file the next day as temperatures started to rise again. The once in the middle right are started from a cold start during day and would fail after ~90 min. The flat once in the front are direct restarts after a failed print.

Few day's later when temperatures dropped again PLA prints just fine :

I can easily recreate the PLA jams as I build my own enclosure with ambient temperature controller to get accurate controlled ambient temperatures each print. With this I can accurately pinpoint at what temp my PLA starts to soften before the 2.2mm to 2mm narrowing causing these jams. Few day's back I forgot I had PET profile selected, resulting in 35C ambient, and when I got back home the PLA was jammed again. Loaded the 22C PLA profile, and print came out fine.

Ya can find all files and stuff about the controller here btw.

If you can print PLA just below 40C, please tell me what your magic tricks are! Pleaaashuuu XD. For the good of all Prusa-kind.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

The hot end PTFE for the MMU2 only has an internal diameter of 1.85, the original had a 2mm id hotend PTFE tube - how do you pull a 2.2mm diameter plug through it, or are you having to remove the PTFE each time and cut the filament off?

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

I was talking about both. My printer started life as a MK2 and became a MK2.5S through several upgrades. As such I have a standard E3D hot end without the 2.2mm step so I don't have the problem of having a blob forming in the PTFE tube liner that is larger than the 2mm heat break. By reducing the ID of the PTFE tube to 1.9mm any blob that forms during print retraction will still pass through the heat break to the nozel unimpeded.

RE: PRUSA edition heat break easily jam/clog with PLA

I know I have some resistance while passing through the PFTE, but I can pull it through with a little jank 😉

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

See my previous response repeated below for convenience:

Ambient temp can raise into the low 40C. I found that the tip on the filament following retraction is approximately the size of the Inside Diameter (ID) of the short PTFE tube that lines the cold portion of the E3D hot end. That being the case I found a PTFE tube of 1.9mm forms a tip of 1.9mm. If the remaining PTFE tubes have a ID of 2.0mm, then no clogs occur on filament load.

In full disclosure the following is my option of the problem based on trial and error and other blog discussions. There are no means of direct observations of that is happening in the hot end that I know of. At best the following is based on theory.:

I believe the blob is occurring when a filament is still viscus when retracted into and above the heat break. When the filament is subsequently advanced to begin printing following a retraction, a blob forms with the diameter of the heat break (2.2mm in your case). The heat break is too cool to re-liquify the blob and a jam occurs. Some people increase the temperature of the hot end to solve the problem but this creates print quality issues. Instead my focus was on eliminating any impediment to the filament advancing to the nozzle. This means that the path from the filament spool to the heat break needs to start smaller than the heat break ID so that the filament entering into the system is guaranteed to pass through to the heat break and beyond without jamming. Here is what I did and it seems to work:

First eliminate the 2.2mm step at the heat break. On small retractions this prevents blobs from forming between the PTFE Liner and the heat break. The easiest way to do that is to install an original E3D hot end. On large retractions or on MMU2 filament changes a blob can form in the PTFE liner larger than the heat break diameter. To solve for this I used a PTFE tube with 1.95mm ID (normal PTFE tubes are 2mm or slightly larger). This still allows 1.75mm filament to pass even if it is 5% over sized as sometimes is the case. Any blob that forms in the PTFE liner will be small enough to pass through the heat break without any resistance.

I hope this helps.

RE: PRUSA edition heat break easily jam/clog with PLA

thanks to all contributing to this knowledge,

I was really frustraded with PLA prints. I do prefer PETG, while at some prints with lots of bridges PLA would perform better. However they failed a lot, some models just always. I burned at least a spool of filament and tried many things:

- build a chamber

- build a temperature control of the chamber

- build an extruder fan (I also had jams on top of the PTFE, a chamber makes this worse)

- changing Z-hop, retract and extruder temperatures and speeds

- finally changing to original E3D heatbrake

Now with the original E3D heat-brake I can print PLA!

I really wish Prusa would give the option to everyone from the start. MMU is super cool. Not being able to print PLA flawlessly is not.

All the cold pulls destroyed some PTFEs and the collet on the heatsink. The collet seems to be fixable with this tiny thing.

Happy printing!

RE: PRUSA edition heat break easily jam/clog with PLA

@karldavy149

My experience is that the exact same print with Prusamont PLA works fine and printing with cheep PLA fails so I am currently exclusively using Prusamont PLA until a standard E3D-V6 heat break arrives.

RE: PRUSA edition heat break easily jam/clog with PLA

@jan-k123

Would you post a link for the "original E3D heat-brake"? Not seeing one in the Prusa store. Having the same issue and want to make sure that I get the right one.

Thanks!

-rp

RE: PRUSA edition heat break easily jam/clog with PLA

Scratch that request. I find the section of this long thread where others discuss it.

Ordered.

RE: PRUSA edition heat break easily jam/clog with PLA

I have the exact same issues with my MK3S. I can print flawlessly with PETG, but with PLA, anything that goes over 2 hours will probably jam at some point where heavy retractions occur. I see the swollen part on the end of the filament when unloaded. After cutting it and reloading the print continous, however those layers get under extruded where the issue occured. This is my only frustration with this printer.

So what is the conclusion on replacing with the E3D standard heatbreak? Does it really help? The last thing I've read from @antimix is that he replaced it and will see what happens. Did it work?

Also since I've never replaced a heat break (although built the MK3S from the kit version) what do I need exactly? An E3D 1.75mm heatbreak some 2mm inside diameter PTFE tubing and a collet? I see there are two kinds of collets in the E3D shop, the clip on, and the embedded one. Which one do I need for the Prusa extruder? Can I use this thermal paste for assembly? (I have some Arctic MX-2 for my PC, but I'm not sure if I can use that here.)

(Also I hope this way I've mentioned antimix, I cannot send PMs yet.)

RE: PRUSA edition heat break easily jam/clog with PLA

Hi Istvan,

Last things first,

Because of the number of Spammers that visit our site, all new members are on moderation for a small number of posts, also, new members are not allowed to send private messages until they are off moderation. if you participate actively in the forum, you will be off moderation soon.

Three of my four prusa's have the prusa specific heatbreak, and are working fine. I believe the issue with blockages using PLA is elsewhere, but as you and many others have decided it is the heatbreak, I will not waste my time trying to change your mind... after all, Joel and others say that is the problem on youtube!

the fourth prusa is a mish mash of parts from many sources if you like, it's a frankenstein prusa (FrankenPrusa) Lol...

that printer has a titanium heatbreak, because I wanted to see what difference it made, in addition to being stronger than stainless steel...

ok.

1, the e3dV6 heatbreak you linked to will fit and work in your Mk3 Printer.

https://help.prusa3d.com/en/guide/how-to-change-a-heatbreak-heatsink-heaterblock-mk3s-mk2-5s-mmu2s_16104 (Change Heatbreak)

Step 26 is really important. Make sure youre PTFE is really well pushed into the heatbreak and that the black embedded collett is pulled away from the heatsink, to lock the PTFE in position!

2, the 2mm inside diameter PTFE 4mm Outside diameter PTFE Will work in the Mk3 Printer

https://help.prusa3d.com/en/guide/how-to-trim-ptfe-tube-original-prusa-printers_22424 (How to trim PTFE for the Prusa Printers)

Some people prefer to use capricorn PTFE tubing, but that has a slightly smaller inside diameter.

3, the Clip on Collett is not really needed if you assemble the rest of the parts correctly, however it will do no harm and it ensures that the black embedded collett is firmly pulled away from the heat sink.

4, the embedded collett that you refer to, is already inside your hot end assembly, they are easily damaged when people first try to dissassemble the hot end, so it's probably worth getting a spare.

5, I have used PC thermal paste with all of my prusa's with the exception of the Mk1, which didn't have a removable heatbreak. so you should be fine. some folk say that Boron Nitride heatpaste is the best... this is a 3D printer, not the space shuttle, you don't need to go for the absolute 'Best'

6, from these questions I assume that you have never dissassembled a hot end before... do yourself a favour, get a spare heater and thermistor. as you may damage them whilst replacing the heatbreak. and even if you don't, you will have spares for your first blob of doom. or natural aging...

7, use a 7mm socket or spanner to loosen your nozzle in preference to pliers (whilst the hot end is HOT) before you dissassemble the extruder... it will make your life easier

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle_2069

this might be a good time to install a new nozzle.

8, be careful when re assembling the extruder assembly, make sure all of your wires are routed correctly, and cable tied into the correct places.

9, don't forget to re check your Live 'Z' for all sheets (Build plates) before you use them again

Good Luck and Happy Printing

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

I didn't have a single clog from the day i mounted a small fan on extuder motor: 40x40mm fan, connected to filament sensor power:

https://www.thingiverse.com/thing:2975582

The point is (as i already stated elsewhere) that combination of motor heat (yes, motor gets quite hot and that heat is transferred through the shaft to gears!) and extruder heat makes gears which drag filament too hot, then when printer makes very small movements filament doesn't flow fast enough through that gears and gets melted. PLA has lowest melting point, that's why only PLA is the problem.

RE: PRUSA edition heat break easily jam/clog with PLA

Hi Joan,

Thank you for this nice and detailed list. Much appreciated!

I'm a bit out of ideas at the moment to what else other to try out. I would be the happiest person, if I could solve it with some magic setting. I've tried many things since I have the printer (last summer) reducing-increasing temperatures/speed/retraction/flow settings, etc. The problem didn't go away, I could only mitigate it by some, but printing never became a click-and-forget process (with PETG it's very close to that, I only have to check the first layers). I've even tried adding an additional fan to the extruder motor by printing a holder and temporarily operating it from a USB power bank. It didn't help anything, it clogged even faster if I remember correctly. The swollen end of the removed filament is exactly that what the photos in this thread show. I'm not trying to force my problem into this category, symptoms matching. Nevertheless, I'm open for any less intrusive ideas to try out.

The HTPLA preset (coming from Joel's video about the problem you've mentioned) with the high temperatures and more aggressive filament flow does help a bit with PLA, but at those layers of the object where mainly the print head moves and very small amount of filament is used partial clogging can still reappear, and it gets under extruded. Also the finish of the object with this profile is nowhere near as good looking as with the default slicer options.

The only thing I've haven't tried is to order a new roll of PLA filament. I'm still using the one came with the printer. (I've only ordered PETG ever since, those work no matter the brand) I'm only using the remaining PLA roll for some small functional prints where I can be sure it's going to finish. But PLA would be much nicer for miniatures, PETG strings even after my best tunings.

I'm thinking about giving another brand a try before jumping the shark and ordering a new heat break. As I've heard some PLAs have a higher melting point and this can help. But the roll came with the printer is something from Prusa which I expect to work properly with the printer, and not be a bad quality one. Is this a realistic thing that another brand would magically solve my problem? The roll is not a Prusament roll though, it can be something sourced from another company, only the box art mentions Prusa.

RE: PRUSA edition heat break easily jam/clog with PLA

the silver filament is plasty mladec.

a czech company

I have used all mine up!

we all have similar but different experiences.

FrankenPrusa is out on loan, all three of my remaining prusa's have the modified heatbreak.

My oldest prusa, came with the standard heatbreak and I changed it out to the Prusa one, when I upgraded to MMU version 1... (Years ago)

did you try Avocado oil on a tissue wrapped around the filament? aparrently that helped matters in joel's video! (Actually oiling filament is a trick from the earlydays of 3d printing from before the Prusa i3 series came on the market!)

I literally use the generic PLA profile, with 0.2mm layer height and 0.4mm retraction for most of my PLA Printing.

If I want a stronger model or a faster printing model I go up to 0.3mm layer height and if I want a stronger Vase Mode print, I use a wider extrusion multiplier usually 0.6 or 0.8 with a 0.4mm nozzle. I have gone as far as 1.2mm extrusion width but that gets raggedy if the walls slope.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

Thanks for the tips!

So it's not a Prusa filament. Maybe it's worth to give another PLA brand a try then.

Excuse me if I'm hesitant to try out cooking oils on my printer which was quiet expensive and shouldn't rely on such workarounds in my book. Maybe I'm just expecting too much. 🤔

0.4mm for retraction length is already something I've tried and it does help, I've found the advice of gutenbar in this forum the second best so far with PLA without going overkill for something like the HTPLA preset. But this print also failed, although a lot later around 6-7 hours into the print with the same extruder clicking/clogging issue. I have an idea to try lowering more the extrusion temperature in combination. (that's something he also suggested for another question). Maybe this helps with PLA expanding over the lip. I don't know, don't have big hopes to be honest. This PLA specify 200-220C extrusion temperature on it's drum, and the default Prusa settings is right in the middle, so shouldn't be a problem, but who knows. Maybe it's really a bad filament and another brand will fix it. Or maybe I should go for the heat break change. Or just give up on PLA and move on.