RE: PRUSA edition heat break easily jam/clog with PLA

Ive been trying to work out this issue for months now, and its still happening, although not quite as often.

Ive put in a new, original e3d (non prusafied) heat break, new nozzle, fan on the exdruder motor thats keeping the temps down nicely, put a collect clip on it, new PTFE tube, so the entirety of the fillament path is replaced. Ive checked the gears, they are seated correctly. Ive messed with tension and temperature, Ive tried everything mentioned on various websites. Ambient temp is now around 19c and getting cooler as going into winter now. No enclosure mk3s. It worked just fine for a year, then sudenly click click click blockage.

It is still somehow creating a blob on the end, despite the heatbreak now being a normal one. Print Im doing now is so far not totaly failed, but every once in a while it will click a couple of times and under extrude, leaving part of a layer thats brittle and only consisting of spots of fillament, but then it will carry on for a while more, before it does it again. I have no trust in it anymore, and short of replacing the entire print head, Ive run out of options. Every PLA print now has missing areas of layers making it look ugly and brittle. I would swap over to PETG (cos that prints just fine) but its more expencive to buy and you dont get the same range of colours.

I really dont know what to do with it now, as Ive got no options left, I would love to know what changed after a year of flawless prints, because none of it makes any sense.

RE: PRUSA edition heat break easily jam/clog with PLA

@joantabb

Agreed with Joan. Just to point out that for me the issue is filament specific. I only have the problem with Colorfabb PA-CF low warp. And it replicated on a different printer (CR10) after I upgrade their stock extruder to e3d (with Titan extruder), which previously just about printed that filament wih stock hotend. I do sometimse have issues with some cheap chinese filaments but to date ALL fixed by modifying the PLA filament profile to print 5C hotter.

After more than 2 years of using the Prusa (and 3 different printers only 1 of which I kept, the CR10), I can say its a highly reliable printer and 90% of my prints are done on it. The e3d standard heatbreak didn't fix the CF issue. It prints just fine with Polymaker PC max and Colorfabb HT/XT/Ngen. It does help when troubleshooting these issues to modify the temperature in your slicer to see if that makes any differences.

Many manufacturers add things to their filament so its well worth looking at your slicer setings before assuming it is hardware related. I nearly went demented with PLA plus mixtures before realising they needed more heat than the generic PLA profile gave them.

RE: PRUSA edition heat break easily jam/clog with PLA

Om my god, this is quit difficult to keep steering my comment and the reaction on the point I tried to make. I will try 😉

@ Protoncek

a. I can only pull it out when hot and with a hard *yank*. so yeah. its all still a bit chewy. But you have a point that I would not expect the plugs to be precise 2.2mm width after that unless that *yank* only temporary deforms it and then returns to its old shape.

b. Don't feel punished... that is the wronge thought and negative thinking. Prusa is finding solutions to problems, and while they might have solved a (potentially) much bigger problem for MMU users, it could also create new problems they did not direcly see. As I personally think the problem we talked about is an combination of events it might be this combination never occured at prusa while testing the redesigned heatbreak to solve the bigger MMU problem.

c. Also, this PLA jamming problem would also be there for MMU and not MMU people. So MMU people are in the same boat as we are in 😉

@ Joantabb,

d. "what was brought in to counter one issue, is now assumed to cause a different problem" -> Exactly, this is not uncommen in engineering 😉

e. If you found a solution, that is great, (I personally tried it) but it did not work for me and I personally would not count it as solution but more of a work arround that might improve it but does not fix the real problem at hand. But this is my (engineering) take on it. I would want to know what is going on exactly and engineer the hell out of it so it is fixed and doesn't need people with less knowledge to go on forums in order to get there PLA prints to work.

f. You bring up your printer list again and everything, but I don't understand why. This *in my opinion* has not much to do with the problem I (and others) lay out here. On the other had, if you had tested the problem we describe here on your machines, that would actually help. But just saying that you have multiple printers is not heling working to a solution. So please, if you want to help prove our thinking wronge. Put those machines (with original heatbreak) in a ~40°C environment. Print a 6hour+ print with prusa gray PLA or something and tell us if it starts jamming for you or not and compare that to your titanium heatbreak version after the same test. That would help greatly. As said many times. I can print perfect in ambient temp below 28-30°C, it only starts jamming above this point for me.

g. "Both of the printers with Modified heatbreaks seem to manage high numbers of filament insertions without jams. " ? I don't get what your trying to say here. This is *to my idea* off-topic. The problem is not with filament insertions, I have never had problems with that. We are talking about jams here, 30min to 2 hour in a 3D print without any filament swapping. Maybe you mean that the 2.2mm modification solved an (mmu) insertion problem? Cause I don't know anything about that.

h. True true, we are both trying to debug and solve problems on our own ways, Thanks for that and keep doing that. No conversation is alway's a loss ;).

i. I would indeed be interested too what prusa is running themselfs. On the other had. I doub't there farm would be 30°C+ ambient temperatures. And I think non of there printes is printing PLA parts (as far as I know) so this would mean that 2 situations needed for the jamms we are talking about here are already missing, so they would not experience these jams.

@ bobstro,

j. Sorry, yeah, I'm thankfull for Joantabb her participations. I follow this post for some time. only her statment "and now it gets blamed for every extrusion issue Lol... " got a bit to my emotions as I feel this problem is not taken serious by people that do not meet the required conditions to get these jamms. For people like me who DO have these conditions and have to face these problems its pretty hard in to face to read some comments being made.

k. I don't think the 2.2-2.0mm step should be hailed as the one and only true fix. Though I also can't deny that it might have added just enough change/extra vriction that jamms are now occuring in situations where it did not (or much more rarely) happen with just the 2.0mm heatbreak. If prusa is going to look at this problem I do not expect them to simply get rid of the heatbreak modification, as this was added for a valid reason I think, but look at the combination of what results in this jam, and engineer toward the best solution for this new problem that has arised. For example : detacht the gears from a thermal connection with the stepper motor. Not pre-heating the filament (with the stepper motor) before entering the heatbreak might already be enough to tip the scale toward almost no jamms anymore even in 40°C ambient area's.

l. I agree with you on not declating a "one true fix" to fast. Physics has often waaaaay more variables that play around a problem then people think.

m. The waving away thing I talked about only was about my frustrations that people mix up unrelated things, clouding the problem we have, and that having people react on those unrelated things and together they end up waving the whole problem itself away while I clearly can reproduce this problem and still have problem with it like many others. So... I might have had a bit of an to emotional reaction at first... sorry.

@ antimix

n. In my oppinion reason C is not the "key". It is just an other new variable in the full physics equation that might have added just enough to start causing jamms in certain moments.

o. Even though replacing it back to the 2.0mm seems to fix it, I'm planning on getting the MMU, so it would get the others problems that prusa wanted solved with this modification. I'm hoping prusa is going to change some other variable to improve this problem in the future.

p. I agree with the most of the first part your problem analysis. This is what I concluded too. I'm don't think its all about the speed thing tough, but more about all situations where you can get the PLA above Glas Temperature at/above the 2.2to2.0mm change. To my experience retractions only increase the change(decreas time) on getting a jam. I don't know about speed. I often print slow (quality mode) and still have this problem. In my oppinion the jams increase with the slower your filament goes (the more time it has to warm up between the gears and inside the heatbreak). Specially printing PLA with a 0.25mm nozzle is almost impossible at higher ambient temps for me.

@ dubgi-aus

q. I agree, my first advice would also be replace heatbreak with a 2.0mm version for now. Or (especially for MMU users) get some way to keep ambient below 28°C. Use an airco or something and keep your enclosure open if you have one.

So the thing I'm hoping to get out of my participation in this discusion to help Prusa deciding on what to do.

Personally I would kinda advice the following :

1 - Do some testing in-house to nail this problem down and see if the original E3D heatbreak indeed fixes the jamming problem.

2 - Then, either find a good alternative solution but this might require some engineering and new part distribution. So I don't expect this to be a fix, but more of a design improvement in the next gen printer.

3 - What I would do however is to include the original (2.0mm) e3D heatbreak in all printers (if this is proven to help), and add the modified heatbreak only in the MMU kits.

4 - Alternatively they could make a note somewhere that it is adviced when printing with PLA to keep ambient below 28°C if jams are experienced 30min to 2 hours in a print. Especially during hot summer day's.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

The 3D Printing Nerd YouTube video that 1st broke this story back in March 2019 shouldn't be overlooked. In addition to the stepped heatbreak, they also discussed other issues and remedies. I'm not a fan of filament oiling -- though it is still apparently a thing on true "all-metal" (no PEI guide tubing) hotends -- but some do swear by it. The ProtoPasta guy identified several issues that can contribute to the failures (including excessive heat, filament moisture absorption, print parameters filament characteristics) and others certainly apply.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

@ bobstro? What do you mean by that this story is broke? Maybe my english is not so good but to my oppinion their findings are for part really valid and in line with my findings and others here.

To my oppinion it is totally related to wether or not your PLA is getting goopy enough (from just the right temperature) above the narrowing in the heatbreak. If this is either from bad filament, wrong settings, high ambient temperature. The thing is, the problem is there. And the known fixes/workarounds : 2.0mm origenal heatbreak, hotter or colder hot-end temps, cooler ambient temps, other filaments types, other retract settings, cooling stepper motor, better cooling heatbreak heatsink. They all point still to the exact same issue in my oppinion.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

@ bobstro? What do you mean by that this story is broke? Maybe my english is not so good but to my oppinion their findings are for part really valid and in line with my findings and others here.

As in "breaking news". A bit of English idiom

The Prusa 2.2-2.0 heatbreak step issue was first brought to widespread public attention by the ProtoPasta guys on that 3D Printing Nerd show. No doubt others were in to it before then.

To my oppinion it is totally related to wether or not your PLA is getting goopy enough (from just the right temperature) above the narrowing in the heatbreak. If this is either from bad filament, wrong settings, high ambient temperature. The thing is, the problem is there. And the known fixes/workarounds : 2.0mm origenal heatbreak, hotter or colder hot-end temps, cooler ambient temps, other filaments types, other retract settings, cooling stepper motor, better cooling heatbreak heatsink. They all point still to the exact same issue in my oppinion.

Absolutely. And don't forget filament feed path alignment and extruder idler friction that can contribute. Over-aggressive slicer settings can also be a problem. Thermal shock from a mis-aligned cooling fan hitting the heater block is yet another.

All of which is to emphasize that it's always worth spending time diagnosing a problem rather than pointing to one solution as a cure-all. Tearing down your printer and wholesale part replacement is not a good 1st step in the process.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

I am interested to see what solution Prusa comes up with.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

I am interested to see what solution Prusa comes up with.

I have no insight with Prusa of course, but I suspect their position is to try the diagnostic steps listed above. Before there was widespread awareness of the stepped heatbreak issue, plenty of people managed to eliminate persistent jams by other means than outright replacement of components. IMO, reducing the factors that cause the stepped heatbreak to jam in the first place is a more effective remedy, and more effective at mitigating heat issues that can cause an array of other jams and issues.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

As a victim of the heat break issue - I can affirm that minor adjustments to print settings will not alleviate the issue. When conditions are right, a jam is unavoidable. About the only thing that can prevent said jam is zero retraction, but that causes as many print issues as the jam itself.

It isn't heat creep, where the heat break is too warm, it isn't ambient too warm where filament gets mushy inside the heat break, it isn't some mysterious setting in the slice. Retractions pump melted filament up the heat break past the cold zone where it cools and solidifies. Unfortunately, the Prusa design with step is near enough to the melt zone that melt makes it past the step, swells and cools.

This image shows it best: the right end has melt, a step up to the diameter of the standard heat break, then a second step up to the Prusa diameter, then a step down to the nominal filament diameter. It shows the clearances of the Prusa step to the melt zone.

Minor assembly differences may add to the issue, but following the E3D assembly guide is not an assurance you won't have this issue. A quarter turn of the heat break can push the step into the melt zone, or far enough away it becomes an issue. Unfortunately Prusa is silent on this and refuses to provide assembly guidance.

Then again, I tried several things to resolve the issue on this print: all were unsuccessful. What finally did work? I changed to the E3D stock heat break.

RE: PRUSA edition heat break easily jam/clog with PLA

@tim-m30

I don't really understand what you are saying if your both not blaming the "melt zone" and at the same time do blame the melt zone?

I think Heatcreep and ambient temperatu are alway's there and effect where the "melt zone" is.

I'm totally not saying your explenation is not true. As mentioned by many, we do think the heatbreak step and restractions also effect where the "melt zone" is. It is just not the only thing that determins where it is, there are a whole lot more variables and I gues even some we did not discus here yet.

For example :

If you where to operate you printer in a 10°C ambient temp. the melt zone would move a bit toward the nozzle (downwards). And as ambient is 40°C the same melt zone would move upwards towards or even above the 2.2mm cross point. In my oppinion retractions both spread/smooshes out the "melt zone" border to a bigger ""transistion" area where plastics gets soft and can get deformed, but is not molten yet. It might also help forming plugs at the 2.2mm narrowing by hammering the filament, but I think the plugs also forms as long as the melt zone is moving up enough.

I don't think it is pumping up molten plastics as in my experience I can see the ends deforming into the plug. You can even clearly see the bontec gear marks dissapearing as the filament is more and more deformed into the pug shape. So in my opinion that means that the "melt zone" (glas transistion point) is just above the 2.2mm narrowing.

So in my opinion not only restraction settings, but anything helping with pushing the melt zone/glass transistion point down under the 2.2mm heatbreak narrowing, or moving or even removing the 2.2mm narrowing all seem to help solve the jamming problem ;). In my case I do this by lowering the ambient temperature if I can do that, but in summer month I need to resort to other tricks like : Printing at night times, printing other platics types like PET, or if I really NEED PLA during day time, I higher the hot end by 10/15°C what I guess moves the meltzone enough above the 2.2mm narrowing to not get jammed anymore as it just melts it above it.

As I said earlyer. I don't think Prusa is going to fix this for our printers right now and I don't expect them to. I just hope our feedback gives work-arounds to people also having these problems. And to make Prusa aware that their current exctruder design seems to have reached some limmits that can result in jams in certain events that should be looked at for future designs and upgrades.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

Interesting. I tend to agree. I wish Prusa would make an official statement.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

I did some basic math on the heat break thermal gradient. It takes a lot of energy change to move the melt zone up the heat break even a few microns. Heat creep, as they say, doesn't really exist in the heat break- IMHO. Contrast that with heat creep at the extruder motor shaft, which is real and testable. Not saying things can't change within the heat break neck, but a quarter turn of thread in the heater block makes more difference than adding 25c ambient. Also, raising nozzle temp 50c doesn't move the cold zone out of the neck either, The design is just too efficient at cooling.

Retraction pumping is a physical process. How far the melt travels is dependent on temps, plastic viscosity, retractions per minute, etc. Some parts are just hammering the pump. Some aren't. That's why only some of us have seen the issue first hand.

No - I haven't modeled the thermals in CAD, but I suspect the neck cools the heat break in a convex shape, a cone of cooler metal extending into the heater block, and the actual melt zone begins well below the thread start (which should be flush with the heater block).

In one extreme case, a guy printing PC at 275c showed photos of the PC coming out of the heat break as a sleeve to the filament along with a stub. Additional evidence the step is always cold enough, even at high print temps.

RE: PRUSA edition heat break easily jam/clog with PLA

@tim-m30

Interesting 😉

Did you also take into account that it is not just the metal heatbreak material that conducts/transports heat up, but also the filament itself?

Do you know what the avarage temp is from your lower part of the hearbreak coolblock? This is not the same as ambient temp.

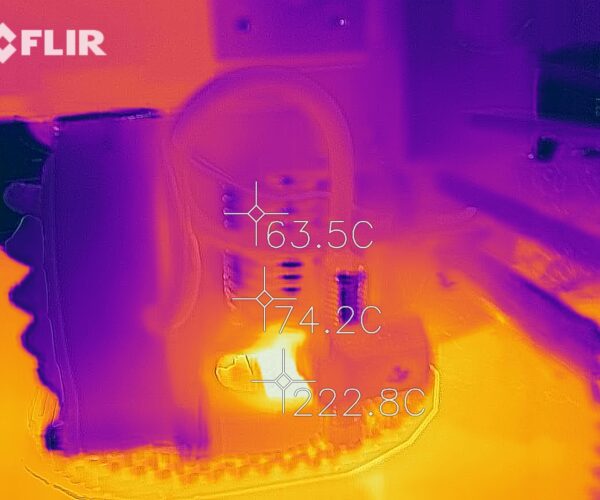

Here an thermal-cam example when I print PETHT filament :

Keep in mind that the measured parts are for a big part reflective surfaces and don't accuratly show correct temps. The heatblock in reality is ~268C on the ourside. The heatbreak measurements might also be higher then measured in the picture.

I measure that the avarage temp of my lower part of the heartbreak coolbock is becomming 73°C in an ambient temperature of 42°C and an heatbed of 110°C. For me personally that would mean the 2.2mm step should be even (far?) higher then 73°C. PetHT has a glass temperature of ~100°C and I have never had it jamm up yet so I would asume that the temp of the 2.2mm step stay's well below 100 but is higher then 73.

Next time I'm printing PLA I will try to get some detailed thermal shots, I might even paint some reflective part black so pictures are more accurate.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

Did you know a thermal camera is not accurate at the imaged resolution? That they have cell to cell bleed over and average the underlying thermal data with a much higher resolution optical sensor?

Unless you get the heat break neck full frame, the data you see is misleading at best, or wrong.

ps: I suspect the heat sink fin is reflecting thermal energy radiated from below. Put the pointer on the coldest parts to get a more accurate read.

RE: PRUSA edition heat break easily jam/clog with PLA

@tim-m30

Hey Tim,

I love to go into a conversation about themal camera's with you but I guess that would be a bit off-topic here 😉

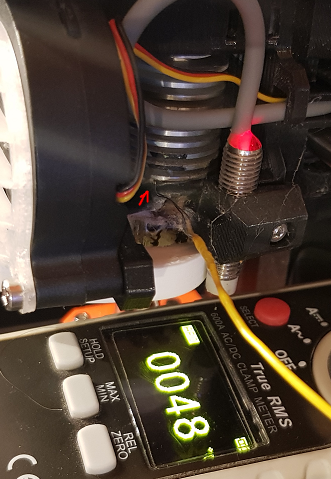

I decided to do some tests for ya to get some data that you might want to see. And to see if I can get some images with less reflections. I painted parts black and compared it with a K-type sensore I shoved in-between the fins with a very small paper behind it to prevent cold air cooling down the sensor from its electical leads.

I have the following situation :

- Only nozzle is heated to 220°C.

- Ambient is 22°C

- No heatbed heating.

- No pre-heated filaments from hot extruder

- No extra heat-creep from retracting hot filament

I measure 48°C in between 2nd lowest fin and 3rd lowest

Now I compare this with a thermal shot of the same situation:

Well.. seems accurate enough to me.

So.. add an ambient temp of +10°C (32°C total) and we are already at 58°C on the outside of the heatsink.

Seems already pretty possible to me to get it above 60°C on the inside.

And then I did not even add :

+ Heatbed from below

+ Heat-creep from filament retractions

+ Pre-heated filament feed from extruder motor.

PS. Keep in mind that the thermal image earlier with 74°C was with an actual PETHT printing process with 270°C Nozzle, 110°C bed, 42°C ambient, extruder motor got ~67°C. So I would guess the 74°C might have been pretty accurate 😉

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

I'm too tired to discuss the futility of trying to measure the heat break in a confined space of the hot end. Based on your test setup, did you know nichrome wire is a great heat absorber? Just an inch will soak up IR and heat a thermocouple, especially wire that has oxidized near the TC weld. Look up thermal shunting error. Valiant effort though.

What we can agree on is the step in the heat break can cause filament jams. All of my jams happened and were testable that the heat break was too cold to melt 2.2 mm ooze that had pumped into that region and cooled.

At the time, heating the hot end to absurd temperatures did not clear the jam: immediately after detecting a jam, raising the nozzle temp the heat break step never melted the PLA I was using (180c to 190c minimum print temp). That said, if you raise the ambient to 50c, nozzle to 275c, then the heat break neck might get hot enough to begin melting some plastics. Seems this works for you.

I found replacing the Prusa heat break with a stock E3D version solved the issue, and have never looked back.

RE: PRUSA edition heat break easily jam/clog with PLA

Two weeks without a jam. I am beginning to believe it was from where I was adjusting my slicer settings. I just got the retraction too high. I went back to the preset settings for PrusaSlicer and Prusament filament. Now no more jams.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

Two weeks without a jam. I am beginning to believe it was from where I was adjusting my slicer settings. I just got the retraction too high. I went back to the preset settings for PrusaSlicer and Prusament filament. Now no more jams.

Sorry @charles-h13, but what combination is working?

I just had my 2nd clone bimetal heatbreak failure on my Sidewinder, essentially adding the 2.2-2.0 step issue to a printer that didn't suffer from it. This time the filament can't be removed at all, and I've replaced it with a basic genuine E3D replacement and all is well. I'm done with clone parts in the filament path.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

@bobstro

Bobstro,

I have about a week of jams and not I have two weeks without a jam.

Changes made:

- I returned to the unedited Prusa Slicer Profile with a 0.2mm layer height. I had edited my file to try and get a ReRapper filament to print without stringiness.

- I switched back to Prusament.

- I cleaned my throat and nozzle with cleading filament.

I really thought it was a fluke, but now I am not sure.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

@antimix

Could you please provide a link to the original E3D heat break?